Ball Valve For Heating SupplyDN 125 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

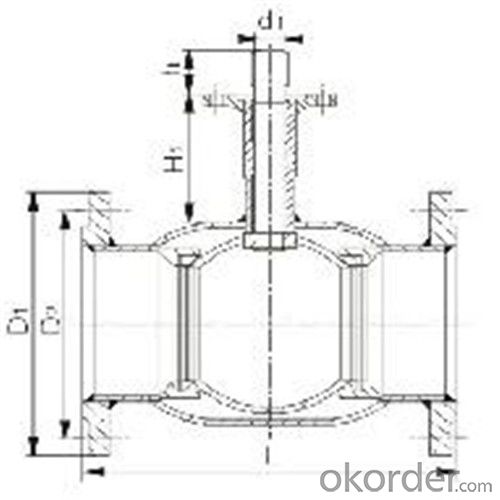

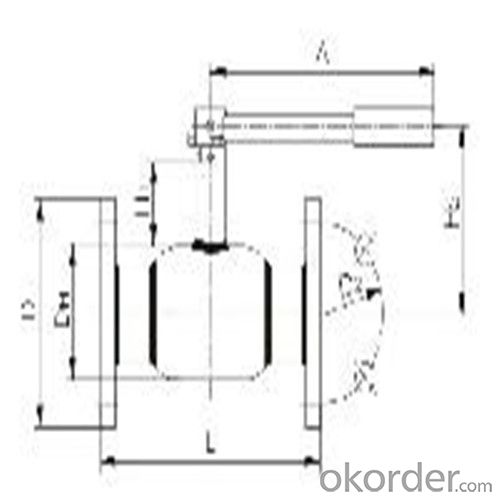

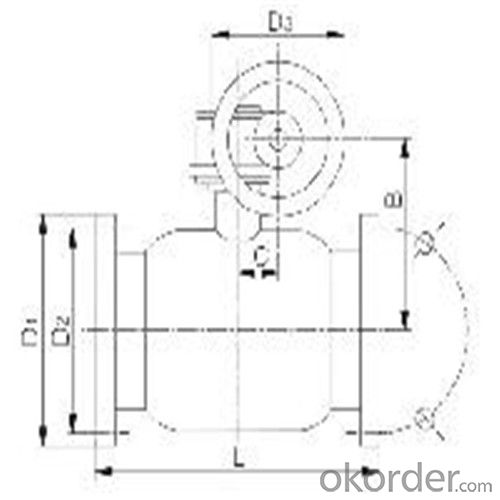

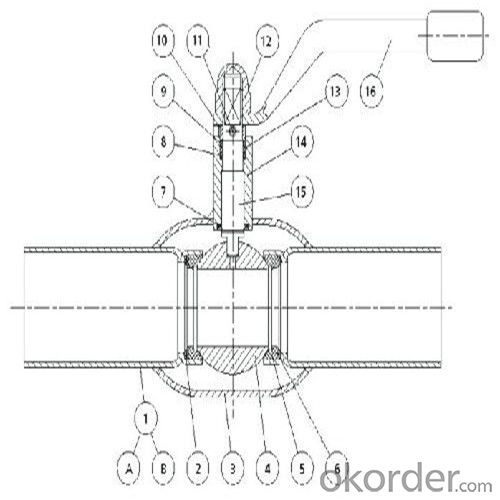

Product Description of Ball valve for heating supply:

Technical introduction

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: whats the location of the pcv valve on on a 2001 bmw 740il (e38)

- In front of the engine slightly to the left and lower area of the throttle valve. It is a round black plastic canister supported by a teardrop shaped rubber with a cable connector at the top and 2 hose connections at the opposite end of the cable connector which are perpendicular to each other. BMW calls it the tank vent valve.

- Q: I have a Jupiter double horn. The thumb valve will randomly stick down and not want to come back up. It however only does this when I play a scale or am in the middle of a song, so when I ask the director or an instrument repair person to help, they think I'm crazy and see nothing wrong with it. Also, the first valve is slightly bent sideways towards the second valve. I got it used and it came like this. It is not horrible, but that makes it significantly slower than the other valves and sticks a LOT. All repair shops do is take my money and claim they've fixed it when they have done nothing. It is so frustrating. What should I do? And the oil doesn't help with either of these things, which is even MORE frustrating.

- Open up the #4 valve cap and flood the top with valve oil, put the cap back on and turn the instrument over. Put valve oil in the crack where the valve comes out of the bottom of the valve case. This can be hard to see. Put some drops on every moving part of the valve action. I can remember the layout of that valve but I don't think you can shoot oil into the valve. Try all that I said above and see if that helps. Rotate and wiggle the valve between each step.

- Q: i have a valve seat pop out and it did some damage my question is can it be fixed i took it to a machine shop the guy look at me with a little confusion he said it cant be done anyone out there have another answer

- Replacing the valve seat can be done, but if there is enough damage, it still may be risky. Swapping the head for a rebuilt one is much safer. You turn in the old head as a core, and no one will even care that is may not be rebuildable. They are only $159, exchange.

- Q: I have three zone valves, two out of the three don't ignite the gas. Once I turn up the thermostat I see the lever on the zone valves move but no gas ignition. Only one of three works fine. Any leads? Thanks!

- you are able to drain this water heater, I try this for a residing, and it fairly is what i might do in case you employed me to come returned restoration your concern. i might siphon off extremely some the water via a hose. turn off the water grant, enable it to relax, undo the feed lines on the suitable, do away with the electrical powered feed line, after shutting it off, or the gas line after shutting it down. locate a sufficiently small hose or plastic tubing to in positive condition into the suitable installation on the tank, start up a siphon and have some buckets waiting to seize the water. shop music of the type of buckets you siphon off and once you have bumped off as much as you are able to, tip the water heater over on that is facet and you are able to then have finished get right of entry to to the previous drain valve to place despite equipment you ought to on it to do away with it. maximum possibly you will in simple terms want to do away with the finished element. In that is place, i might propose a 4 x 3/4 galv. nipple with an entire circulate ball valve for a drain. The ball valve ought to have 3/4 lady threads on the two ends and you will get an adapter installation to pass from the pipe thread to a hose thread. you will not have confidence how common it fairly is going to be to empty your heater then. as quickly as you have each thing put in, set if back up and reattach on the suitable, hook up gas source and verify to thoroughly fill the tank, bleeding all the air out of it earlier turning on the electrical powered, despite if it fairly is electrical powered.

- Q: We have a 2005 GMC Sierra 1/2 ton truck that has a check engine light on. The dealer checked the code and he told us we need a new Evap Vent Valve and clamp. The cost is over 500.00 with labor being most of the cost. Is this diffcult to change out? Im a very mechanical person. Also he said it would be ok to drive for now but could cause problems down the road. ????like what?My wife is getting ready to take a trip in it, should it be ok for awhile? Dont have 500+ to spend on it now.

- Theres 2 valves . 1 is electronic , the other is a manual valve in the canister. The valve is normally in the charcole canister. These canisters have been pretty much the same design for years. You could probably find another at a junk yard to fit , even if it was a different year/body. Seeing how a code finder found it . It's probably the electronic valve. It is a simple open close valve. 1 connector and usually 2 vacuum lines. You can also plug the line going to the intake. this will prevent a lean mixture from an unregisted air leak. The valve is used to direct tank vapors that accumulate in the canister at start up. At start up the valve opens and the engine sucks gas vapor from the canister . once the engine is started the valve closes .Vapor gas has a quicker ingnition point then liquid gas. A quick fix would be to simply plug the line going to the intake , with a bolt or screw to fit the end of the hose. This is only to prevent a lean mixture from air getting in behind the mass air flow sensor. The light on the dash will come on when the O2 sensor in the exhaust smell the lean mixture thats not being adjusted by the injectors as told to do. I run an older multi port fuel injected truck and have compleatly blocked all the emmisions systems off and removed them. It's only an emmisions device , it has nothing to do with the preformance of the engine (unless it allows a leak). Just plug it and have no worries of it becoming a problem

- Q: I want to switch off the water in the bathroom only due to replacing sink taps, will water still come out of the pipe if i turn the stop valve

- Assuming that the stop valves are good, turning them off will stop the flow of water to the sink taps. To test them, turn on the water faucet at the sink, then turn off both stop valves. The water should stop coming out of the faucet. If it continues to drip, the stop valves are defective and should be replaced when you do the job. If this is the case you'll have to shut off the main water valve or a valve upstream of the stops to replace them. Good Luck

- Q: Or could you put a blow off valve on a supercharger?

- Supercharger Blow Off Valve

- Q: Is there a product that can fit over a foot valve to give it further protection in muddy water? I am looking for something for forest firefighting in mind. Something like a screen box something else that can give it further protection. It would be nice if it was small, and compact. Pictures would definitely be an asset. Thanks to everyone that answers. Greatly appreciated.

- most foot valves i have bought come with a strainer attached perhaps you should look for that type. if your valve has a strainer you may consider making a further coarse strainer out of a ball of chicken wire and place this over the foot valve assembly(thats what i do for the cold water supply to my house) don't compress the chicken wire very small as it will block up i tie the wire filter on with galvanized wire then i can easily replace it if necessary ps i tried stainless steel pot scourers but they were to fine and blocked easily

- Q: Was wondering if there is something I could purchase to put into a car so that it will become a 24 valve????

- Time to drop out of your software then. You did no longer even attempt - you in basic terms decrease and paste an common quiz devoid of even inclusive of the linked diagrams, and anticipate us to unravel it. Why could we do this? you haven't any longer even attempted. i do no longer want you getting close to a motor vehicle in any technical means in any admire in case you could no longer answer those questions.

- Q: ive had my yz250f for more than a year and i havent had the valves adjusted......it still starts up in under 5 kicks and rides great.......are there any signs that indicate you need your valves adjusted besides not being able to start it?

- With titanium valves you do not wait until they start ticking. It is a race bike not a Ford Pinto. Do I need to define the term preventative maintenance? They need to be checked a minimum of once a year, if not more. Don't wait for problems, take it in now. As to super cleats answer, I'm sure the factory riders would love to know your secret for making a 4 stroke race bike start on the first kick every time, because they sure haven't figured that one out yet.

Send your message to us

Ball Valve For Heating SupplyDN 125 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords