Antique glazed tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

rackle glazed tiles

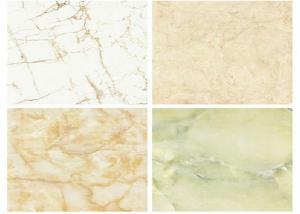

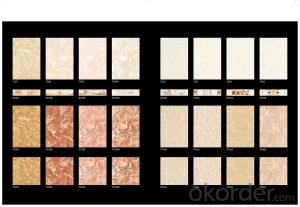

A fine layer of pigment and color have been applied on the surface of the tiles. The colors are plentiful. The glaze layer is crackle artistically. They are suitable for many applications, such as for wall decorations, Pillars & Columns, artwork, furniture, baths, kitchens etc. We also can supply the tiles with one edge or two round, which are perfect for installation need. This series also can partner with various kinds of accessories to form a perfect art concept for your imagination.

Specification

1) Size: 3ft× 9ft, 3ft× 6ft, 2ft× 6ft, 6ft× 6ft, 4ft× 4ft, 2ft× 4ft, 2ft× 2ft, 2ft× 8ft etc.

2) Lead Day: About 1 month

3) Available in various colors

4) Excellent color fade resistance

5) Acid and alkali resistance

6) Durable

7) Washable

8) Unique artistic style

9) Crackle glaze

10) Ideal for bathrooms, kitchens, wall decorations, Pillars & Columns, artwork, furniture etc.

- Q: What are the considerations for steel structure design in earthquake-prone areas?

- When designing steel structures in earthquake-prone areas, several considerations need to be taken into account. Firstly, the structure should be designed to resist the seismic forces generated during an earthquake. This involves understanding the local seismicity and ground motion characteristics, and selecting appropriate design parameters such as the design earthquake magnitude and ground acceleration. Secondly, the structural system should be designed to ensure ductility and energy dissipation. This means incorporating features that allow the structure to deform and absorb seismic energy without collapsing, such as using moment-resisting frames or braced frames. The connections between structural elements should also be carefully designed to provide sufficient strength and ductility. Another consideration is the choice of materials and construction techniques. Steel, with its high strength and ductility, is often preferred for seismic-resistant structures. The construction process should also be carried out carefully, ensuring proper quality control and adherence to design specifications to maintain the structural integrity. Lastly, regular inspection and maintenance of the steel structure are crucial to ensure its long-term performance. This includes checking for any signs of damage or deterioration, repairing or strengthening as necessary, and conducting periodic seismic assessments to evaluate the structure's capacity to withstand future earthquakes.

- Q: How are steel structures used in disaster-resistant buildings?

- Steel structures are commonly used in disaster-resistant buildings due to their exceptional strength and durability. Steel's high tensile strength allows it to withstand extreme forces, such as earthquakes, hurricanes, and heavy snow loads, without collapsing. Additionally, steel structures can be designed with flexible joints and connections that can absorb and dissipate energy during seismic events, reducing the risk of structural failure. The use of steel in disaster-resistant buildings ensures increased safety and resilience, protecting occupants and minimizing damage during natural disasters.

- Q: How are steel structures used in the construction of resorts?

- Steel structures are commonly used in the construction of resorts due to their strength, durability, and versatility. They are used to create the framework and support systems for various resort buildings such as hotels, restaurants, and recreational facilities. Steel structures offer the ability to span large distances, allowing for open and flexible design layouts. Additionally, steel is resistant to corrosion, which is crucial in coastal or humid resort locations. Its use in resort construction ensures a safe and sturdy environment for guests while also providing architects and designers with the freedom to create unique and aesthetically pleasing structures.

- Q: What are the design considerations for steel mezzanine platforms?

- Some design considerations for steel mezzanine platforms include load capacity, structural stability, access points, safety features, and integration with existing infrastructure. The platform should be designed to support the anticipated load, ensuring that it can safely accommodate the intended use. Structural stability is crucial to prevent any collapse or deflection, requiring careful analysis and design of the support structure. Access points such as stairs, ladders, or ramps should be included to provide safe and convenient entry and exit. Safety features like guardrails, handrails, and non-slip surfaces should be incorporated to minimize the risk of accidents. Lastly, the design should take into account the integration with the existing infrastructure, considering factors like clearance height, utility connections, and fire safety requirements.

- Q: What are the different types of steel canopies and walkways?

- There are several different types of steel canopies and walkways available, including cantilever canopies, gable canopies, and barrel-vault canopies. Walkways can also vary in design, such as straight walkways, curved walkways, and elevated walkways. Each type offers unique features and benefits, catering to specific aesthetic and functional requirements.

- Q: What is the role of steel in residential buildings?

- The role of steel in residential buildings is crucial as it provides structural support, ensuring the strength and stability of the building. Steel is commonly used in beams, columns, and foundations, allowing for open-floor plans and the ability to withstand various loads, such as the weight of the structure, occupants, and external forces like wind or earthquakes. Additionally, steel offers durability, fire resistance, and design flexibility, making it an ideal material in construction for creating safe and aesthetically pleasing residential spaces.

- Q: How are steel structures used in theme hotels and resorts?

- Steel structures are commonly used in theme hotels and resorts due to their strength, versatility, and cost-effectiveness. These structures are utilized in various ways, such as creating unique and eye-catching architectural designs, constructing large open spaces, and supporting heavy loads. Steel provides the necessary structural integrity for creating themed elements like large-scale sculptures, bridges, and extravagant facades. Additionally, steel structures allow for faster construction times, making them an ideal choice for meeting tight project deadlines in the hospitality industry. Overall, steel structures play a crucial role in bringing the imaginative and immersive experiences found in theme hotels and resorts to life.

- Q: What are the common maintenance requirements for steel structures?

- The common maintenance requirements for steel structures include regular inspections for corrosion or damage, cleaning to remove dirt or debris, repainting or re-coating to prevent rust, and addressing any structural issues or repairs that may arise over time.

- Q: What are the considerations for designing steel structures for high wind zones?

- When designing steel structures for high wind zones, several considerations need to be taken into account. Firstly, the structure should be designed to withstand the highest possible wind speeds expected in the area. This involves calculating wind loads and selecting appropriate materials and structural members with sufficient strength and stiffness. Secondly, the overall shape and geometry of the structure should be carefully considered. Aerodynamic shapes with smooth surfaces can help reduce wind resistance and minimize the impact of high winds. Additionally, the arrangement and orientation of the structural members should be optimized to ensure efficient load distribution and minimize wind-induced vibrations. Next, the connections between structural members become crucial. Strong and reliable connections are essential to ensure the integrity of the overall structure. Proper detailing and welding techniques should be used to secure the connections and prevent failure due to wind forces. Furthermore, the foundation of the steel structure should be designed to resist uplift and lateral forces caused by strong winds. Adequate anchoring systems and proper soil analysis are essential to ensure the stability and safety of the structure. Lastly, it is important to consider potential dynamic effects caused by wind gusts or vortex shedding. These effects can induce resonant vibrations and potentially cause fatigue failure. To mitigate this, appropriate damping mechanisms and aerodynamic features can be integrated into the design. Overall, designing steel structures for high wind zones requires a comprehensive understanding of wind effects, proper material selection, careful geometric design, reliable connections, robust foundations, and consideration of dynamic effects.

- Q: Can steel structures be designed to be self-cleaning or low-maintenance?

- Yes, steel structures can be designed to be self-cleaning or low-maintenance. Various strategies can be employed to achieve this. One method is to use a high-quality protective coating on the steel surface, such as a galvanized or powder-coated finish. These coatings provide a barrier against corrosion and dirt accumulation, making it easier to clean the structure. Additionally, the design can incorporate features that promote self-cleaning, such as sloped surfaces or strategic placement of rainwater collection systems to naturally wash away dirt and debris. Furthermore, advancements in nanotechnology have led to the development of self-cleaning coatings that use photocatalytic materials to break down organic matter and prevent dirt from sticking to the surface. Overall, with proper design considerations and the use of appropriate protective coatings, steel structures can be made self-cleaning or low-maintenance, reducing the need for frequent cleaning and maintenance efforts.

Send your message to us

Antique glazed tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords