3DK Type Coal Excavation High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The splash or forced lubrication will be used for the power end with the characteristics of small size,compact structure,stable driving,lower frication coefficient,low temperature and suitable for long time operation.

◆The pump can be applied to coal excavation with high pressure water jetting,hydraulic liquid supply in the metallurgy,shipping rust elimination,basic engineering,liquid transportation,engineering and pressure test for various rubber hose,metal tube and oil well as well .The medium to be pumped can be clear water and some other chemical liquids as well.

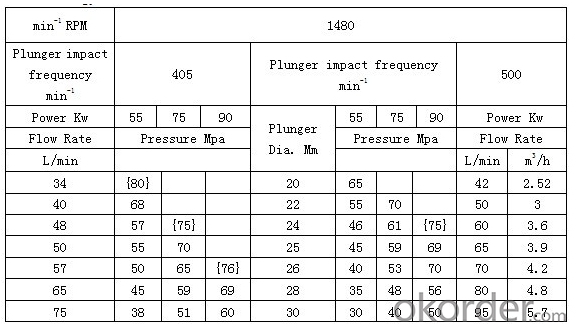

◆Technology Parameters

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: How to install circulating water pump for cooling tower?

- Water pump, cold water pump and hot water pump, the specific installation depends on the location of the cooling tower and the location of the heat exchanger, high cooling tower position, the need for hot water pump, heat exchanger position high.The cooling tower, cooling tower (Cooling tower), is using water as coolant, from a system to absorb heat emissions to the atmosphere, heat exchanged to produce steam, steam heat to volatile evaporation dissipation, convection and radiation heat transfer principle to disperse industrial waste heat or refrigeration and air conditioning to reduce evaporation cooling device therefore, in order to ensure the normal operation of the system, device as a barrel. The cooling tower can be divided into natural ventilation cooling tower and mechanical ventilation cooling tower according to its ventilation mode.

- Q: where is water pump tempertuer sensor in ford focus 2002

- Water-pumps do not have temperature sensors. They're (temperature sensors) always located in the water-jacket of the hottest part of the engine which is the cylinder head. The water-pump coolant temperature is by far the coolest. It's located to the right of the alternator, a few inches facing forward screwed into the cylinder head. The little manual in the glove compartment will not explain where the coolant temperature sensor is.

- Q: All the water to my house comes from the river close by - via a 1500kw surface pump, into a large pressurised tank. If there is ever any kind of blockage in the pipe - or if it freezes ...this causes the pump to run - 'dry' - which eventually burns out the motor. I have lost 2 pumps so far because of running dry - and they are very expensive.I would like to fit some kind of automatic cut-out - that will ALWAYS stop the pump running after 15 minutes or perhaps less - as that is ALL the time it needs - if the water is flowing freely - to fill the pressurised tank. I feel sure such a thing must exist - but I do not know what it is called or where to buy one. Does anyone know of a 'switch' of this kind? And where to look for one? What could I put into google to do a search - for suppliers and prices, please?

- There are pressure switches that have a low water cut out on them.If the pressure drops too low the switch will turn the pump off.This however my not be a 100% cure.If you used just enough water to turn the pump on and then shut the flow of water off and the pump was not pumping water for the reasons you stated it would continue to run and not build up enough pressure to turn it off.If you wanted to do some sort of timer you could contact an electrician and ask about a timer that could be acctivated when the pump comes on. I am not aware of any thing on the market made for this but a good electrician would know where to get the right components to do this.

- Q: Who knows? Is the motor with a pump a squirrel cage induction motor?

- Should be a squirrel cage motor for winding asynchronous motor for high torque applications. For example, its structure and the hoist crane cage motor with different rotor loop it can slip ring external resistor. The motor rotor circuit principle know that certain external resistance can reduce the starting current, but also can improve the rotor circuit power factor and torque. The pump load does not need large torque. So it should be the squirrel cage induction motor.

- Q: I am looking for a small water pump that I can turn on and off using a computer, preferably via USB. If someone could please post a link or a method of me doing this myself, I will be very appreciative.

- Well I am going to tell you the best site that I have found about USB I/O. Here we can get USB Lab digital Input and Output data acquisition interfaces series are available in many different configurations. They support a wide variety of industrial automation I/O control, test and measurement applications by USB. For more details visit the following link and enjoy ...

- Q: Installation position of check valve for water pump

- Check valves must be installed at the pump's exit and position before the outlet control valve for servicing the check valve.Jiang Yuanyuan 1985's statement has a problem:1. On the flow of water, because the fluid is continuous and incompressible, the water in any part of the pipe will not flow as long as it is cut off in any position in the pipe.2, self suction exhaust is formed within the pump in outlet pipe, check valve installed in the inlet, because the pressure is low, is not conducive to automatically open the check valve, and its resistance, easy to form a vacuum pump and cavitation.

- Q: I have a 1990 js550 that i picked up for a project. When in the water it overheats and minimal water comes out the tell tail. When on the tap it runs fine no overheating, so i disconnected the hose from the back of the ski where it sucks the water in and ran a garden hose directly to it. And the ski ran fine.I also cleaned all the tubes out with air.I am not getting enough water flow through the ski when it is in the water. Is there a water pump inside the motor?There is definitely no blockages, there is just no enough pressure to keep it cool.Thanks

- Hey Sam, It's Jeff again. I used to own a stand-up ski a while back, and I had the same problem. The water to the motor comes from the jet pump, the more RPM, the more pressure, There should be enough pressure to keep the motor cool at low RPM, but if not then there are a couple of things to check. Since you already eliminated a blockage in the motor buy disconnecting the pickup, first check the actual pickup for a restriction from the entrance to the connection you took the hose off at. If that's OK, then the clearance in the jet pump itself could be excessive. A ski with a lot of hours in sandy water can have pump wear that isn't really noticeable when cruising, you might notice it a little under heavy acceleration when leaving the no wake zone. Under idle there just isn't enough pressure to cool the motor. You can have it fixed for not to much, a little hard to do yourself. To save a planned day on the lake you can always get a cheep inline electric water pump. My last thought though, since your other question was about a slow cranking starter, I'd pull the plugs and spin it over to see if it spits water out the cylinders. It doesn't hurt just to eliminate a blown head gasket. As a side note, I like them a lot better then the big sit-down style, they're much more free then the bigger ones. It's like the difference between a motorcycle and a car. If you want to do the stuff the bigger ones do, buy a boat.

- Q: My car was is leaking antifreeze. One guy told me without even l putting it up in the air to check it that it was the radiator. The second guy I took it to said it is the water pump. He told me a total of six hundred sixty one dollars to replace it. I went to pep boys and was told eight hundred sixty two. I have a 2000 grand am se.

- It depends what engine you have. If it is a V6 3.4... the labor is only .5 and the water pump is about $65.00, and one gallon of Dexcool is $21.33. Sounds like $661.00 is far off. If you have a 2.4 engine, the water pump is quite complicated to replace, as it is in the rear bottom of the engine and driven by the timing chain. I replaced one when I worked in a shop. Notice I said ONE? Those are a More than likely you have a 2.4 with a price like that. That is also not a bad price, being that the pump runs about $50.00, but the labor is about 9.5 hours to install it. Make sure the diagnosis was properly done. The water pump on the 2.4 is a far cry from the radiator. The water pump bolts into the back of the timing cover, and the back flange on the pump bolts to another flang on the water pipe back there. There is also a bypass pipe that has an o-ring on it that pops into the pump. If it is just that o-ring leaking, you will save a ton of money.

- Q: This is what it is doing- the actual pump that is in its own little shed CLICKS all of the time water is being ran, even a small amount of water. The water pressure goes to a slow trickle and eventually stops completely. After about 20-30 minutes I go back and check the spickets and the water is fine, but quickly repeats this same cycle. We just installed this pump about 3 weeks ago. It was doing fine until last week. Does it need to be primed or pressure switch settings increased or decreased? Or am I talking totally out of my head?!

- Its either faulty, or was installed wrong.

- Q: What is the difference between a low pressure pump and a high pressure pump?

- High pressure pump head, large power! High pressure pump, low pressure pump has no strict limit

Send your message to us

3DK Type Coal Excavation High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords