3DN-S Type High Pressure Slurry Injection Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

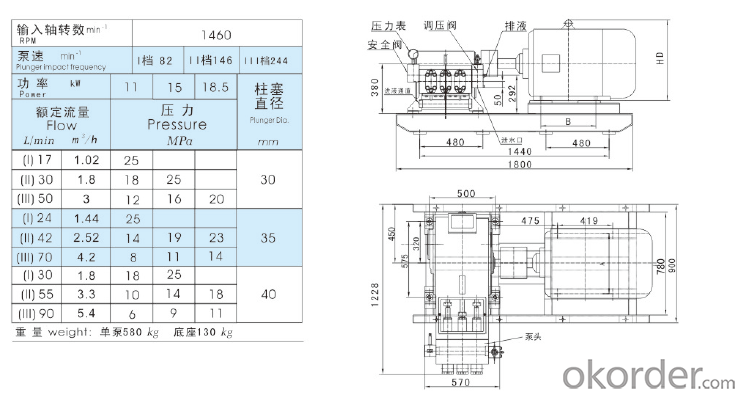

The slurry 3DN is a new type product, specially designed for the leakage blocking and suited for the waterproof wall in underground engineering, breast wall, leakage blocking in mine, wall protection in well and some basic engieering etc. It is a kind of light, special, high pressure pump with fixed flow rate and the medium to be pumped can be clear water, some liquids with particles or viscous fluid as well as slurry with high density.

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: How to prevent freezing of an air pump in cold temperatures?

- To prevent freezing of an air pump in cold temperatures, there are a few measures you can take: 1. Insulate the air pump: Wrap the air pump with insulation material to protect it from the cold air. This can be done using foam or insulating tape, ensuring that all exposed parts are covered. 2. Use a heat source: Place a heat source near the air pump to keep it warm. This can be a heat lamp, a heating pad, or even a small heater. Just make sure to place it at a safe distance to avoid any potential hazards. 3. Keep the pump running: One of the most effective ways to prevent freezing is to keep the air pump running continuously. The constant movement of air can help prevent the buildup of condensation and subsequent freezing. Consider using a timer to ensure the pump doesn't turn off during the night or when not in use. 4. Store the pump indoors: If possible, bring the air pump indoors when temperatures drop significantly. Storing it in a warmer environment will greatly reduce the risk of freezing. 5. Use a de-icer: Consider using a de-icer specifically designed for air pumps. These products can be added to the pump's intake or directly into the water to prevent freezing. Follow the manufacturer's instructions for proper usage. Remember, taking precautions to prevent freezing is crucial as it can damage the pump and reduce its effectiveness. By insulating, providing heat, keeping it running, storing it indoors, or using a de-icer, you can ensure the longevity and functionality of your air pump even in cold temperatures.

- Q: Can an air pump be used in high-altitude areas?

- Yes, an air pump can be used in high-altitude areas. However, it is important to note that the performance of the air pump may be affected by the reduced air pressure at higher altitudes. The lower air pressure means that the pump will have to work harder to achieve the desired level of inflation or pressure. Additionally, some air pumps may have a limited altitude range specified by the manufacturer. Therefore, it is advisable to check the specifications of the air pump and ensure it is suitable for use in high-altitude areas before purchasing or using it.

- Q: Can an air pump be used for inflating air loungers with cup holders?

- Indeed, air loungers with cup holders can be inflated using an air pump. This handy device proves to be quite efficient in rapidly inflating a variety of inflatable items, including air loungers. Usually, air loungers with cup holders come equipped with valves that seamlessly connect to an air pump. By employing the air pump, one can effortlessly achieve the desired level of firmness in the air lounger, enabling a pleasant and relaxing experience while keeping their preferred beverage conveniently nearby.

- Q: How small can an air pump be?

- An air pump can be as small as a few centimeters in size, depending on its intended use and technology used.

- Q: Can an air pump be used for reducing moisture in a space?

- Using an alternative structure and phrasing: Regrettably, an air pump does not possess the potential to diminish moisture within an area. Its primary function is the transportation of air between locations, typically employed to inflate or deflate objects. The extraction of moisture from the air necessitates the implementation of a dehumidifier or a ventilation system, explicitly engineered to eliminate surplus moisture from the environment.

- Q: Can an air pump be used for inflating inflatable play structures?

- Yes, an air pump can be used for inflating inflatable play structures. In fact, it is the most common and convenient method of inflating these structures. Air pumps are designed to provide a continuous flow of air into the inflatable play structures, allowing them to quickly inflate to their full size. They are typically equipped with various nozzles and adapters to fit different valve sizes on the inflatable play structures. It is important to ensure that the air pump has enough power and airflow capacity to inflate the particular play structure you have, as some larger structures may require a more powerful pump. Additionally, it is recommended to follow the manufacturer's instructions for proper inflation and safety precautions.

- Q: What's the difference between an air pump and an air compressor?

- Difference:The basic principle is the same. Only in the structure is not the same, the air compressor inlet and exhaust valves are, the exhaust air pump is usually straight.Explanation:The air pump (Q. B ng air pump), namely "air pump", a device for removing air or add air from the enclosed space from a closed space. The air pump is mainly divided into an electric air pump and a manual air pump. Electric air pump. An electric pump powered by electricity; produces air pressure by constantly compressing the air through electricity. Mainly used in pneumatic rubber, car inflatable, etc..The air compressor is the base of product of modern industry, electrical and automation is often said that there is full pneumatic meaning; and the air compressor is to provide power source, pneumatic system is the core equipment of electromechanical drainage main source device, it is the prime mover (usually motor) into mechanical energy conversion device of gas pressure can, is the pressure of compressed air generator.

- Q: Can an air pump be used for inflating air fryers?

- No, an air pump cannot be used for inflating air fryers. Air fryers are kitchen appliances that use hot air circulation to cook food, and they do not require any kind of inflation. Inflating air fryers would not be necessary or beneficial for their operation. They are designed to function by heating the air inside the appliance, not by inflating it.

- Q: What is the maximum flow rate an air pump can achieve?

- The achievement of the maximum flow rate by an air pump relies on multiple factors, including the pump's size, design, power source, pressure capabilities, and intended use. Generally, air pumps can attain flow rates that vary from a few liters per minute to several hundred liters per minute. Furthermore, industrial-grade air pumps, equipped with larger motors and greater pressure capabilities, can even achieve higher flow rates, reaching several thousand liters per minute. When determining the necessary maximum flow rate from an air pump, it is essential to carefully consider the specific requirements and limitations of the application.

- Q: How does an air pump handle variations in ambient temperature?

- An air pump is designed to handle variations in ambient temperature by incorporating various mechanisms and components. Firstly, the materials used in its construction are selected to withstand different temperature ranges. This ensures that the pump can operate efficiently and without any damage or malfunction in both high and low-temperature environments. Additionally, air pumps often include temperature sensors that continuously monitor the ambient temperature. These sensors provide feedback to the pump's control system, allowing it to adjust its operation accordingly. For example, if the temperature rises, the pump may increase its cooling mechanisms or adjust its speed to prevent overheating. Conversely, if the temperature drops, the pump may activate heating elements or adjust its speed to maintain optimal performance. Moreover, air pumps may have insulation or heat dissipation mechanisms to regulate the internal temperature within the pump. Insulation helps to retain heat in cold environments, preventing any freezing or damage to the internal components. On the other hand, heat dissipation mechanisms such as fans, heat sinks, or vents assist in dissipating excess heat generated during operation in hot environments. Overall, an air pump is designed to handle variations in ambient temperature through a combination of temperature sensors, control systems, material selection, insulation, and heat dissipation mechanisms. These features ensure the pump can adapt to different temperature conditions, maintain optimal performance, and prevent any damage or malfunction.

Send your message to us

3DN-S Type High Pressure Slurry Injection Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches