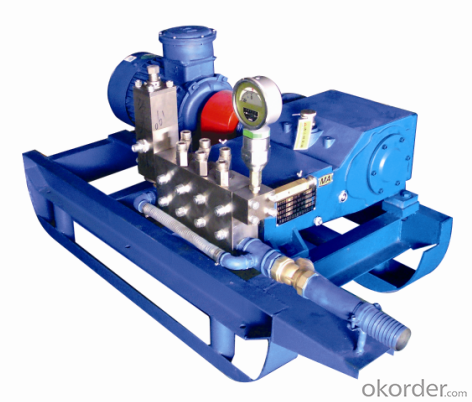

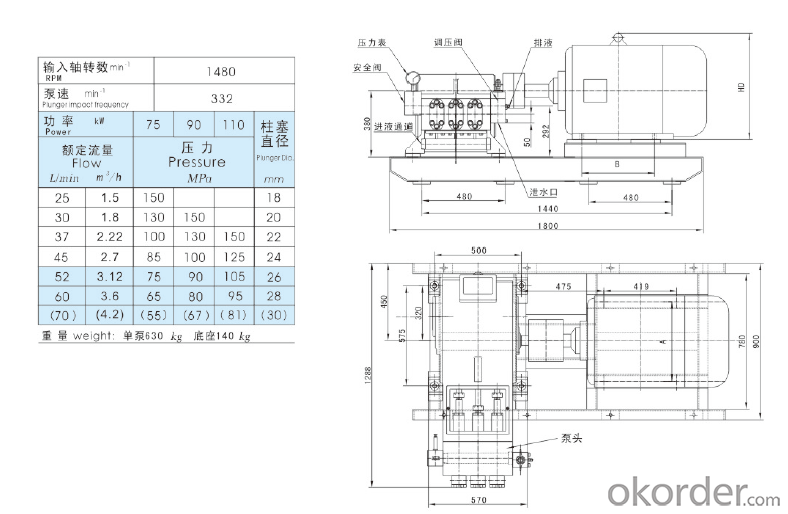

3D2D-S Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The pump 3D2D is impoved on the basis of the pump 3D2A and the liquid end is newly designed into a horizontal and straight-line manifold, which solved the problem of manifold strength very successfully with the characteristics of compact structure, easy to operate and maintain. The pump is suited for ultra-high pressure water jetting, metal cutting, shipping rust elimination, condenser, heat exchanger, evaporation pot, and boiler cleaning in the suger and power plant as well as various vessels and reactors. The medium to be pumped can ne clean water, emulsion and some other chemical liquids.

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: Can an air pump be used for pneumatic tools?

- Yes, an air pump can be used for pneumatic tools. Pneumatic tools require compressed air to operate, and an air pump is designed to generate and deliver compressed air.

- Q: How long does an air pump take to fully charge?

- The time required for an air pump to fully charge can vary depending on the specific model and its charging capabilities. It is best to consult the user manual or product specifications for accurate information regarding the charging time.

- Q: What is the energy source for an air pump?

- The energy source for an air pump can vary depending on the type of pump being used. In general, air pumps can be powered by electricity, batteries, or manual operation. Electric air pumps typically use an electrical outlet as their energy source, while battery-powered pumps rely on disposable or rechargeable batteries. Manual air pumps, on the other hand, require physical exertion to generate the necessary pressure for pumping air. It is important to select the appropriate energy source for an air pump based on the intended use and portability requirements.

- Q: How to calculate the required air flow rate for a specific application?

- In order to calculate the necessary air flow rate for a particular application, several factors must be taken into account. First and foremost, the volume of air required for the application needs to be determined. This can be achieved by assessing the size of the space or equipment that requires air supply. For instance, if the air flow rate for a room's ventilation system is being calculated, the dimensions of the room (length, width, and height) need to be measured and multiplied to determine the volume. Subsequently, the air change rate necessary for the application must be considered. This refers to the frequency at which the air in the space needs to be replaced within a specific time period. Different applications have varying requirements for air change rates, which depend on factors such as occupancy levels, industry standards, and air quality needs. For example, a laboratory may require more frequent air changes compared to an office space. Once the volume of air and the required air change rate have been determined, these values can be multiplied together to calculate the necessary air flow rate. This will provide the amount of air that needs to be supplied or circulated within the specified time frame. It is important to note that additional factors like air quality requirements, temperature control, and pressure differentials may need to be taken into consideration based on the specific application. Seeking advice from a professional in the field, such as an HVAC engineer, can ensure accurate calculations and proper system design for optimal performance.

- Q: Can an air pump be used for powering air brakes in vehicles?

- An air pump is not suitable for powering air brakes in vehicles. Instead, a specialized system called an air compressor is required. Unlike a simple air pump, air compressors are designed to generate and maintain the high pressure necessary for air brakes to function effectively. They are capable of providing a constant supply of compressed air to the brake system, ensuring consistent and reliable braking performance. Regular air pumps are not equipped to handle the high pressure demands of air brakes and would not be able to generate the required pressure for safe and effective operation. Therefore, it is crucial to use a designated air compressor specifically designed for powering air brakes in vehicles.

- Q: How does an air pump prevent water foaming in fish tanks or aquariums?

- The prevention of water foaming in fish tanks or aquariums is achieved through the use of an air pump, which enhances the oxygen levels in the water. When air is directed into the aquarium via an air stone or diffuser, bubbles emerge and ascend to the water's surface, causing movement and agitation. This motion aids in breaking the surface tension of the water and promoting gas exchange, enabling the escape of carbon dioxide and the dissolution of oxygen. By upholding a higher concentration of oxygen in the tank, the air pump effectively impedes the accumulation of organic waste and excessive nutrients, which can be catalysts for foam formation. Moreover, the augmented water movement facilitated by the air pump also promotes the even distribution of heat and nutrients throughout the tank, ensuring a healthier and more stable environment for the fish and other aquatic organisms.

- Q: Can an air pump be used for air pollution control systems?

- Yes, an air pump can be used for air pollution control systems. Air pumps, also known as air blowers or air compressors, can be used to supply air to various components of air pollution control systems such as air scrubbers, catalytic converters, and particulate matter filters. These systems work by removing or reducing pollutants from the air, and an air pump plays a crucial role in providing the necessary air flow to facilitate the pollutant removal processes. The air pump helps to create the required pressure or vacuum needed for the efficient operation of these pollution control systems. Additionally, air pumps can also be used to transport or distribute treated air in ventilation or exhaust systems, further contributing to air pollution control efforts.

- Q: How efficient is an air pump in terms of energy consumption?

- When it comes to energy consumption, an air pump is widely regarded as a highly efficient device. Its efficiency is determined by the amount of energy needed to produce a specific amount of airflow or pressure. In comparison to similar equipment, air pumps are recognized for their efficiency. Typically, air pumps utilize electric motors to compress air. These motors have become more efficient over time, thanks to technological advancements that reduce energy consumption. Additionally, air pumps are designed to minimize air leaks and optimize the transfer of energy to the compressed air, further enhancing their efficiency. The efficiency of an air pump can vary depending on factors such as the model, size, and intended use. However, on average, air pumps are able to convert a significant portion of electrical energy into compressed air. This level of efficiency is advantageous as it reduces energy waste and leads to cost savings for the user. External factors such as air temperature, humidity, and the condition of the pump itself can influence the efficiency of an air pump. To maintain and improve efficiency, regular maintenance, proper sizing, and usage within recommended operating conditions are important. All in all, an air pump is considered an energy-efficient device due to its effective conversion of electrical energy into compressed air. Its efficiency makes it a preferred choice for various applications, including tire inflation, operating pneumatic tools, and powering air compressors in industrial settings.

- Q: Are air pumps powered by electricity?

- Yes, air pumps are typically powered by electricity. Most air pumps available in the market require an electrical power source, such as a wall outlet or batteries, to operate. These pumps use an electric motor to generate the necessary force to compress and push air into various objects, such as tires, inflatable mattresses, or sports equipment. However, it is worth noting that some air pumps may have alternative power sources, such as hand-operated pumps or rechargeable batteries, but the majority of them rely on electricity.

Send your message to us

3D2D-S Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches