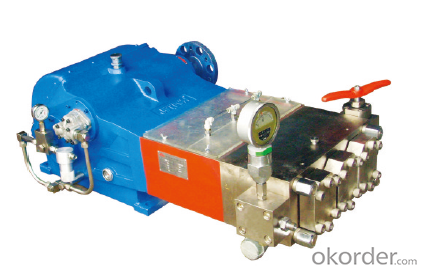

3D3Q-S Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

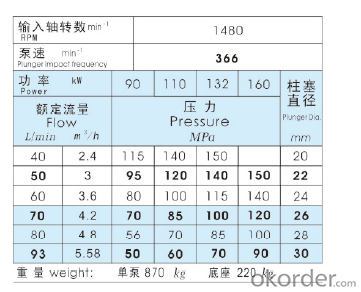

The technology for our high pressure pump was introduced from JETECH and the flow rate can reach 40L/min to 93L/min at the maximum pressure 150MPa, which is suitable for ultra-high pressure cleaning, metal exchanger, evaporation pot, and boiler cleaning in the sugar and power plant as well as various vessels and reactors. The medium to be pumped can be clean water, emulsion and some other chemical liquids.

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: How can I solve the water in the air pump?

- Oil water only three problems, one is the thrust cylinder gasket, cylinder two is a water trachoma or bad, three is the ring of oil cooler.

- Q: How to prevent air leaks in inflatable structures?

- To prevent air leaks in inflatable structures, there are various precautions you can take: 1. Prior to using the inflatable structure, carefully examine it for any signs of damage or wear. Conduct a visual inspection to identify punctures, tears, or loose seams. If any issues are detected, repair them before inflating. 2. Place a protective ground cover or tarp underneath the inflatable structure to shield it from sharp objects or rough surfaces that may cause punctures. 3. Securely anchor the structure to the ground or other stable structures. Implement stakes, sandbags, or other suitable methods to prevent it from being blown away or exerting excessive stress on the seams. 4. Avoid over-inflation, as this can strain the seams excessively and heighten the risk of leaks. Adhere to the manufacturer's instructions and recommended pressure levels to ensure proper inflation. 5. Regularly inspect and maintain the structure to identify any signs of damage, wear, or leaks. Assess the seams, valves, and other potential weak points. Immediately repair minor leaks or damage using a suitable repair kit or adhesive recommended by the manufacturer. 6. Keep the inflatable structure away from sharp objects such as sharp branches, furniture edges, or tools to minimize the chance of accidental punctures or tears. 7. Properly store the inflatable structure in a clean, dry, and secure location when not in use. Avoid exposing it to extreme temperatures, direct sunlight, or other harsh environmental conditions that could degrade the material over time. By following these preventive measures, you can ensure the durability and safety of your inflatable structure by minimizing the risk of air leaks.

- Q: How can the piston ring of the air pump not burn engine oil?

- Hello: the piston ring can not be matched first, that is, the gap of the ring can not be placed in the same place. I hope my answer can help you.

- Q: Can an air pump be used for inflating air fryers?

- No, an air pump cannot be used for inflating air fryers. Air fryers are kitchen appliances that use hot air circulation to cook food, and they do not require any kind of inflation. Inflating air fryers would not be necessary or beneficial for their operation. They are designed to function by heating the air inside the appliance, not by inflating it.

- Q: Can an air pump be used for inflating air cushions for outdoor seating?

- Indeed, air cushions for outdoor seating can be inflated using an air pump. Air pumps are specifically designed to inflate and deflate a range of objects, including air cushions. They offer a speedy and efficient means of inflating air cushions, which is far more time-saving and effortless compared to manual inflation techniques. Furthermore, certain air pumps are equipped with diverse nozzle attachments, enabling the effortless inflation of air cushions of various types and sizes. Consequently, employing an air pump proves to be both a convenient and practical approach to inflating air cushions for outdoor seating.

- Q: How does an air pump affect gas mileage in vehicles?

- The gas mileage of vehicles can potentially be affected in various ways by an air pump, also referred to as an air injection system. The main objective of an air pump is to introduce fresh air into the exhaust system in order to assist in minimizing harmful emissions. By infusing fresh air into the exhaust, the air pump encourages the burning of unburned fuel, resulting in a cleaner exhaust and decreased emissions. Nevertheless, the functioning of the air pump does require energy, which is generally obtained from the vehicle's engine. Consequently, the air pump can cause a slight reduction in overall efficiency and gas mileage. The engine needs to exert a slightly greater effort to power the air pump, which in turn necessitates the burning of a small additional amount of fuel. It is worth noting that the impact on gas mileage is usually negligible, particularly in modern vehicles equipped with more advanced air injection systems. The advancements in engine technology and overall efficiency have significantly mitigated the adverse effects of the air pump on gas mileage. Ultimately, while there may be a slight effect on gas mileage, the primary purpose of an air pump is to minimize emissions and ensure compliance with environmental regulations. The advantages of cleaner air and reduced pollution outweigh any minor decrease in fuel efficiency.

- Q: Can an air pump be used for blowing up inflatable toys?

- Yes, an air pump can be used for blowing up inflatable toys.

- Q: What are the common features of an air pump?

- The common features of an air pump include a motor or engine, an air intake or suction port, an air outlet or discharge port, a pressure gauge, and a control or switch to turn the pump on and off. The motor or engine is responsible for powering the pump and creating the necessary airflow. The air intake or suction port allows the pump to draw in the surrounding air or gas. The air outlet or discharge port is where the compressed air or gas is expelled after it has been pressurized. The pressure gauge is used to monitor and regulate the pressure of the air being pumped. Lastly, the control or switch allows the user to start or stop the pump as needed. These features are commonly found in various types of air pumps, such as those used for inflating tires, aquariums, or air mattresses.

- Q: How does an air pump handle continuous operation?

- An air pump is designed to handle continuous operation by incorporating durable components, such as a robust motor and high-quality bearings, that can withstand the constant usage without overheating or breaking down. Additionally, it may have built-in cooling mechanisms, like a fan or heat dissipation system, to regulate the temperature and prevent any damage due to prolonged operation.

- Q: How to prevent clogging of the air outlet of an air pump?

- To prevent clogging of the air outlet of an air pump, there are several steps you can take: 1. Regularly clean and maintain the air pump: Dust, debris, and other particles can accumulate in the air pump over time, leading to clogging. Clean the air pump regularly using a soft brush or cloth to remove any accumulated dirt. 2. Use a pre-filter or sponge: Placing a pre-filter or sponge over the air intake can help trap larger particles before they enter the air pump. This can prevent clogging and extend the life of the pump. 3. Position the air pump properly: Ensure that the air pump is positioned in a well-ventilated area that is free from dust and dirt. Avoid placing it on the ground or near any potential sources of debris that could get sucked into the air pump. 4. Avoid overloading the air pump: Each air pump has a recommended maximum output capacity. Exceeding this capacity can put strain on the pump and increase the likelihood of clogging. Refer to the manufacturer's guidelines for the appropriate usage and avoid overloading the pump. 5. Check and clean the air tubing: Over time, the air tubing can accumulate dirt, algae, or other substances that can lead to clogging at the outlet. Regularly inspect the tubing and clean it by running a brush or cloth through it to remove any blockages. 6. Use a check valve: Installing a check valve at the outlet of the air pump can prevent water or debris from flowing back into the pump, reducing the risk of clogging. By following these preventive measures, you can minimize the chances of clogging the air outlet of an air pump and ensure its efficient operation.

Send your message to us

3D3Q-S Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches