3D1 Type High Pressure Explosion-proof Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The pump can be equipped with the explosion-proof motor 7.5 to 22 kw and the medium to be pumped can be clear water and emulsion as well.

◆That pump can be applied for dust removal affusion, hydraulic support and coal excavation and also can be used for surface cleaning, such as excavation equipments and pipes etc., as well as pressure test.

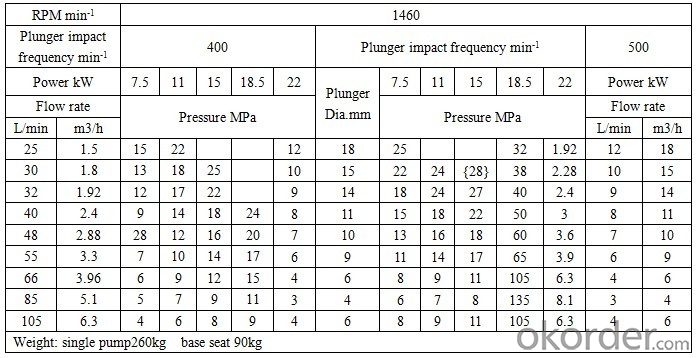

◆Technology Parameters

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: Want to spray model, so into the suitable for beginners with the gas pump + HD130, but not quite understand, with 012, there are a few problems, I hope to get the experience of guidance, kneeling thank you1: spray color spray for a long time when (15 ~ 20 minutes) paint (paint model) will be holding water sprayed out of ||||, why? Is there any way you can work it out? Is there anything I've missed?2: I heard that the air pressure can be adjusted, isn't it? Is it possible to control the range of jet pressure more freely? (that is, if you want to spray small places, you can adjust the small, large range of jet can be increased?) Found that part of the barometer, in addition to air filter has a marked "0" to "9" 10 figures can be, things turn, is that thing? If you can adjust, please spray model, how much better value of spray color?

- 1. when the weather is wet, the water jet is normal.2. air filter, we also called oil-water separator.It feels like you have two empty filters, and mine is the one with the red circle.A red circle, the oil-water separator above the barometer of the dark here, pull it up, can be rotated to adjust the voltage and then left.The general air pressure is about 2 kilograms.

- Q: Are there air pumps suitable for medical use?

- Air pumps specifically designed for medical use are available. These pumps are utilized in various medical settings, including hospitals, clinics, and home healthcare. Their purpose is to provide a constant supply of compressed air for different medical applications. To guarantee the delivery of clean and dependable air, medical air pumps are designed to meet specific safety and performance standards. They are typically equipped with filters and moisture separators, which eliminate contaminants and maintain the purity of the delivered air. Moreover, these pumps are often designed to be noiseless or have low noise levels to prioritize patient comfort and minimize disturbance. Medical air pumps have several common applications. Firstly, they are used in respiratory therapy to power respiratory devices like ventilators, CPAP machines, and nebulizers. These devices aid patients with breathing difficulties, sleep apnea, or asthma by facilitating easier breathing. Secondly, medical air pumps are utilized in wound care. They play a crucial role in negative pressure wound therapy (NPWT), which promotes wound healing. These pumps create a controlled vacuum environment around the wound, aiding in the removal of excess fluid and promoting tissue regeneration. Lastly, medical air pumps are employed in surgical procedures to power pneumatic tools such as surgical drills or bone saws. These pumps ensure a continuous source of air pressure, which is vital for the proper functioning of these tools during surgery. It is important to emphasize that healthcare professionals should guide and supervise the use of medical air pumps. Proper maintenance and regular servicing of these pumps are crucial to ensure their reliability and safety in medical settings.

- Q: My previous air pump was 0.25, and then the pump head and motor were wasted. Only the cylinder. If the pump head and the motor can hit 12 pressure cylinders, can they stand it?The pump head is big and the rated pressure is 12. I was wondering if the cylinder 0.25 can stand it

- Pressure is mainly organic, is installed in reverse, /0.25 can play 12 high voltage, to the money, a cylinder back loaded Caixing Oh!

- Q: Is it necessary to have a pressure gauge on an air pump?

- Yes, it is necessary to have a pressure gauge on an air pump. The pressure gauge allows you to monitor and control the amount of air being pumped into a tire or any other inflatable object. It ensures that you do not overinflate or underinflate, which can lead to potential safety hazards or damage to the object being inflated.

- Q: How does an air pump handle continuous use?

- An air pump is designed to handle continuous use by utilizing durable materials, efficient cooling systems, and automatic shut-off features to prevent overheating. Additionally, regular maintenance, such as cleaning and replacing worn-out parts, ensures optimal performance and longevity.

- Q: How long does an air pump take to deflate an inflatable object?

- The time it takes for an air pump to deflate an inflatable object depends on various factors such as the size of the object, the pressure at which it was inflated, and the power of the air pump. However, in general, it usually takes a few minutes to completely deflate an inflatable object using an air pump.

- Q: How to make a simple oxygen pump?

- Oxygen in the water can be increased through the flow of water, not necessarily to the water filling oxygen. Just as the living creatures in the river do not lack oxygen, a reason, because the river is flowing.Understand this principle, oxygen pump is not so complicated. To get a small motor or engine, and power, then the gear in a motor with a plastic or metal sheet made of water,, fan blades and so can, anyway, let the water flow up fast. Just fine. But it's better to buy one than waste so much. Small power pump is only 56 yuan, a little more than ten yuan. At least in terms of electricity, than homemade safety..

- Q: What are the different pressure settings for air pumps?

- The pressure settings for air pumps can vary depending on the specific model and purpose. However, common pressure settings for air pumps can range from low pressure settings such as 1-5 PSI (pounds per square inch) for inflating small objects like balloons or inflatable toys, to higher pressure settings such as 20-30 PSI for tasks like inflating car or bicycle tires.

- Q: What is the recommended air pressure for inflatable kayaks?

- The optimal air pressure for inflatable kayaks may vary depending on the specific model and brand. However, it is generally recommended to inflate the kayak to a pressure of approximately 1.5 to 2.5 PSI. To determine the precise range, it is crucial to consult the manufacturer's instructions or the kayak's manual. Overinflating the kayak can lead to excessive rigidity and potential bursting, while underinflating it may compromise stability and performance. It is advisable to utilize a pressure gauge or a pump equipped with a built-in pressure indicator to ensure accurate inflation. Regularly monitoring and maintaining the air pressure in your inflatable kayak is indispensable for optimal performance and safety while on the water.

- Q: How does an air pump handle vibrations?

- An air pump typically handles vibrations by incorporating various mechanisms such as shock-absorbing mounts or dampeners, which help to minimize the impact of vibrations on the pump's internal components. Additionally, manufacturers may use robust materials and designs to ensure the pump's stability and reduce the effects of vibrations.

Send your message to us

3D1 Type High Pressure Explosion-proof Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords