Extruded Aluminum Bar Stock

Extruded Aluminum Bar Stock Related Searches

Extruded Aluminum Stock Extruded Aluminum Frame Stock Anodized Aluminum Bar Stock Aluminum Extrusion Stock Polished Aluminum Bar Stock Aluminum Rectangular Bar Stock Extruded Aluminum Fence Stock Stock Aluminum Bar Aluminum Extrusions Stock Bending Aluminum Bar Stock Aluminum Round Bar Stock Brushed Aluminum Bar Stock Aluminum Stock Bar Cutting Aluminum Bar Stock Round Aluminum Bar Stock Solid Aluminum Bar Stock Aluminum Extrusion Shapes Stock Cold Bending Aluminum Bar Stock Aluminum Square Bar Stock Extruded Aluminum Stock Shapes 1 X 2 Aluminum Bar Stock Anodized Aluminum Flat Bar Stock Aluminum Bar Stock For Sale 1 Inch Aluminum Bar Stock Knurled Aluminum Bar Stock Aluminum T Bar Stock Metric Aluminum Bar Stock Aluminum Tee Bar Stock Aluminum Triangle Bar Stock Aluminum Flat Bar StockExtruded Aluminum Bar Stock Supplier & Manufacturer from China

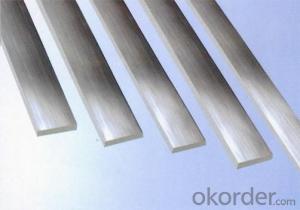

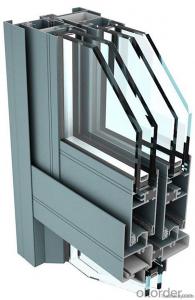

Extruded Aluminum Bar Stock is a type of aluminum material that has been processed through an extrusion process, resulting in a strong and lightweight bar with a variety of shapes and sizes. This material is known for its excellent strength-to-weight ratio, making it an ideal choice for a wide range of applications. The versatility of extruded aluminum bar stock allows it to be used in various industries, such as construction, automotive, aerospace, and consumer electronics. Its durability and resistance to corrosion make it a popular choice for both functional and decorative purposes.In terms of usage, extruded aluminum bar stock is commonly employed in structural components, frameworks, and support systems. It can also be found in applications requiring high strength and rigidity, such as in the manufacturing of machinery parts, transportation equipment, and various engineering projects. The product's lightweight nature and ease of fabrication make it a preferred material for many designers and engineers, as it can be easily cut, machined, and formed into the desired shapes without compromising its structural integrity.

Okorder.com is a leading wholesale supplier of extruded aluminum bar stock, boasting a vast inventory that caters to the diverse needs of various industries. As a reliable source for this product, Okorder.com ensures that customers have access to high-quality extruded aluminum bar stock at competitive prices. By maintaining a large inventory, Okorder.com is able to provide prompt delivery and excellent customer service, making it a go-to destination for businesses and individuals seeking extruded aluminum bar stock for their projects.

Hot Products