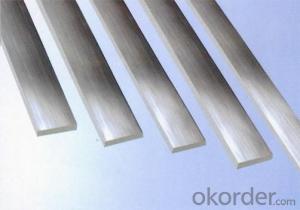

Aluminum Flat Bar Stock

Aluminum Flat Bar Stock Related Searches

Anodized Aluminum Flat Bar Stock Flat Aluminum Stock Aluminum Flat Bar Stock Near Me Aluminum Square Bar Stock Flat Stock Aluminum Black Aluminum Flat Stock Aluminum Stock Bar Aluminum Flat Stock For Sale Stock Aluminum Bar Aluminum Hollow Bar Stock Buy Aluminum Bar Stock Aluminum Bar Stock Price Aluminum Round Bar Stock 1 4 Aluminum Flat Stock Aluminum Bronze Bar Stock Solid Aluminum Bar Stock Anodized Aluminum Flat Stock Aluminum Bar Stock For Sale White Aluminum Flat Stock Aluminum Flat Stock Prices Aluminum T Bar Stock Aluminum Triangle Bar Stock Metric Aluminum Bar Stock Anodized Aluminum Bar Stock 1 Aluminum Bar Stock 1 2 Aluminum Bar Stock 1 4 Aluminum Bar Stock Aluminum Rectangular Bar Stock Polished Aluminum Bar Stock Bending Aluminum Flat StockAluminum Flat Bar Stock Supplier & Manufacturer from China

Aluminum Flat Bar Stock is a versatile metal product known for its strength, lightweight properties, and excellent corrosion resistance. It is widely used in various industries such as construction, automotive, aerospace, and manufacturing due to its ability to withstand harsh conditions and maintain structural integrity. This product is also favored for its ease of fabrication and finishing, making it a popular choice for custom applications and designs.Aluminum Flat Bar Stock is utilized in numerous applications, including structural components, framework, and decorative elements. It is particularly useful in scenarios where weight reduction is a priority, such as in the transportation sector where fuel efficiency is crucial. Additionally, its non-magnetic and non-sparking properties make it an ideal material for environments where safety is a concern, such as in the oil and gas industry or for use in electrical installations.

Okorder.com is a reputable wholesale supplier of Aluminum Flat Bar Stock, offering a vast inventory to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Aluminum Flat Bar Stock they provide meets the highest industry standards. Their extensive range of products allows customers to find the specific dimensions, grades, and finishes required for their projects, making them a one-stop solution for all aluminum flat bar stock needs.

Hot Products