Grade ASTM A36 Carbon Steel Round Bar Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade ASTM A36 Carbon Steel Round Bar Stock

Details of Grade ASTM A36 Carbon Steel Round Bar Stock

Name | Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of Grade ASTM A36 Carbon Steel Round Bar Stock

| Product name | ASTM A36 carbon steel round bar |

| Dimensions | 15-150mm |

| Length | 6-12m |

| Standard | ASTM,BS,GB,JIS |

| Grade | Q195 Q235 20# 45# A36 SAE1020 |

| Brand | CNBM |

| Application | Mild Steel Round Bar is used for making security grills, screens, Construction and Machine Manufacture. |

| Finish condition | hot rolled |

| Appearance | new |

| Sales mode | factory direct sales |

| Quality assurance | mill test certificate is provided, third party inspection is acceptable |

| Trade term | FOB/CIF/CFR |

| Payment term | 30%T/T in advance, balance against B/L copy;Sight irrevocable LC |

| Delivery time | Within 15-30 days after receiving original LC or deposit, also according to the quantity |

| Certification | ISO9001:2000/BV |

| Product name | ASTM A36 carbon steel round bar |

| Dimensions | 15-150mm |

| Length | 6-12m |

| Standard | ASTM,BS,GB,JIS |

| Grade | Q195 Q235 20# 45# A36 SAE1020 |

| Brand | CNBM |

| Application | Mild Steel Round Bar is used for making security grills, screens, Construction and Machine Manufacture. |

| Finish condition | hot rolled |

| Appearance | new |

| Sales mode | factory direct sales |

| Quality assurance | mill test certificate is provided, third party inspection is acceptable |

| Trade term | FOB/CIF/CFR |

| Payment term | 30%T/T in advance, balance against B/L copy;Sight irrevocable LC |

| Delivery time | Within 15-30 days after receiving original LC or deposit, also according to the quantity |

| Certification | ISO9001:2000/BV |

CNBM Introduction of Grade ASTM A36 Carbon Steel Round Bar Stock

| Product name | ASTM A36 carbon steel round bar |

| Dimensions | 15-150mm |

| Length | 6-12m |

| Standard | ASTM,BS,GB,JIS |

| Grade | Q195 Q235 20# 45# A36 SAE1020 |

| Brand | CNBM |

| Application | Mild Steel Round Bar is used for making security grills, screens, Construction and Machine Manufacture. |

| Finish condition | hot rolled |

| Appearance | new |

| Sales mode | factory direct sales |

| Quality assurance | mill test certificate is provided, third party inspection is acceptable |

| Trade term | FOB/CIF/CFR |

| Payment term | 30%T/T in advance, balance against B/L copy;Sight irrevocable LC |

| Delivery time | Within 15-30 days after receiving original LC or deposit, also according to the quantity |

| Certification | ISO9001:2000/BV |

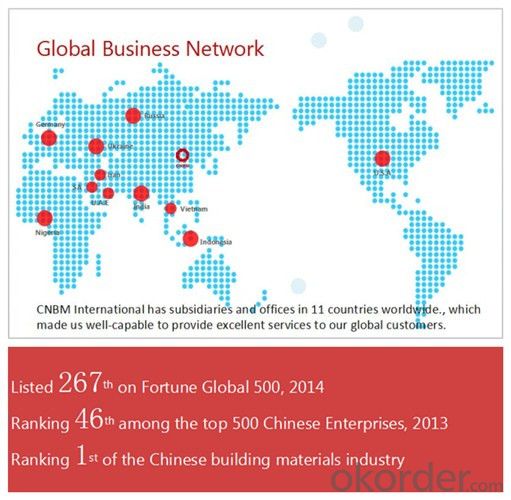

CNBM Introduction of Grade ASTM A36 Carbon Steel Round Bar Stock Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Grade ASTM A36 Carbon Steel Round Bar Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What is the significance of carbon content in special steel?

- The carbon content in special steel is significant because it determines the steel's hardness, strength, and overall performance. Higher carbon content results in increased hardness and strength, making the steel suitable for applications requiring durability and resistance to wear and tear. On the other hand, lower carbon content enhances the steel's ductility and formability, making it more suitable for shaping and molding processes. Therefore, carbon content plays a crucial role in tailoring the properties of special steel to meet specific industrial requirements.

- Q: How does special steel perform in high-speed machining operations?

- Special steel is specifically designed to perform well in high-speed machining operations. It has unique properties that make it ideal for cutting, drilling, and shaping at high speeds. Firstly, special steel has excellent thermal conductivity, which means it can effectively dissipate heat generated during the machining process. This is crucial in high-speed operations as excessive heat can cause tool wear and deformation. By efficiently transferring heat away from the cutting edge, special steel helps to prolong tool life and maintain dimensional accuracy. Secondly, special steel has high hardness and strength, which allows it to withstand the intense forces and pressures encountered during high-speed machining. This enables it to maintain its shape and integrity, reducing the chances of tool breakage or deformation. Moreover, its high strength also ensures that the machined parts have excellent durability and resistance to wear. In addition, special steel exhibits good machinability, meaning it can be easily cut and shaped with minimal effort. Its composition and microstructure are optimized for efficient chip formation and removal, ensuring smooth operations and reducing the risk of chip clogging or tool jamming. Furthermore, special steel often contains alloying elements such as chromium, molybdenum, and vanadium, which enhance its resistance to corrosion and wear. This is particularly important in high-speed machining operations, where the cutting tools and workpiece are in constant contact. The improved corrosion and wear resistance of special steel contribute to longer tool life and improved surface finish. Overall, special steel is specifically engineered to excel in high-speed machining operations. Its thermal conductivity, hardness, strength, machinability, and resistance to corrosion and wear make it a preferred choice for applications that require fast and precise metal removal.

- Q: How does stainless steel contribute to the construction industry?

- Stainless steel contributes to the construction industry by providing durability, corrosion resistance, and aesthetic appeal. Its strength and resistance to rust make it ideal for structural components, such as beams, columns, and reinforcement bars. Stainless steel is also commonly used for architectural elements like cladding, handrails, and fixtures due to its sleek appearance and low maintenance requirements. Overall, stainless steel enhances the longevity and aesthetics of buildings, making it a valuable material in the construction industry.

- Q: Can special steel be used for musical instruments?

- Yes, special steel can be used for musical instruments. Special steel alloys, such as stainless steel or carbon steel, can be utilized in the manufacturing of various musical instruments like drums, cymbals, or even certain parts of wind instruments. These steel alloys offer unique tonal qualities and durability, making them suitable for creating distinctive sounds and withstanding vigorous playing.

- Q: How does special steel perform in terms of corrosion resistance?

- Special steel, also known as stainless steel, performs exceptionally well in terms of corrosion resistance. Due to its high chromium content, it forms a passive layer on its surface that protects it from rusting and corrosion in various environments. This makes special steel suitable for a wide range of applications, including in marine, chemical, and food processing industries, where resistance to corrosion is crucial.

- Q: How is special steel used in the oil and gas industry?

- Special steel is used in the oil and gas industry for various applications such as manufacturing drill pipes, casings, and pipelines, as well as components for offshore platforms and equipment. It is highly resistant to corrosion, high temperatures, and extreme pressures, making it suitable for harsh environments and ensuring the integrity and safety of infrastructure in the industry.

- Q: What are the factors that affect the fatigue strength of special steel?

- The factors that affect the fatigue strength of special steel include the composition of the steel, the heat treatment process used, the presence of impurities or defects, the surface finish, the loading conditions, and the operating environment.

- Q: What are the common defects found in special steel?

- Some common defects found in special steel include surface defects such as scratches, pitting, and scaling, as well as internal defects like cracks, voids, and inclusions. These defects can negatively impact the mechanical properties and performance of the steel, compromising its strength, durability, and corrosion resistance.

- Q: Can special steel be used for making aerospace components?

- Yes, special steel can be used for making aerospace components. Special steel alloys, such as stainless steel or titanium alloys, possess high strength, excellent corrosion resistance, and good heat resistance, making them suitable for aerospace applications where lightweight, durability, and resistance to extreme conditions are essential.

- Q: How does special steel contribute to the agriculture aftermarket industry?

- Special steel plays a crucial role in the agriculture aftermarket industry by providing high-performance components and equipment that enhance productivity and efficiency in farming operations. Special steel, also known as alloy steel, is engineered to have specific properties such as strength, durability, corrosion resistance, and heat resistance, making it ideal for various agricultural applications. One of the key contributions of special steel to the agriculture aftermarket industry is the production of durable and reliable machinery parts. These parts, such as plowshares, blades, and tines, are subjected to harsh conditions, including intense wear, impact, and exposure to corrosive substances. Special steel components can withstand these challenges and offer extended service life, reducing downtime and maintenance costs for farmers. Furthermore, special steel is used in the manufacturing of agricultural equipment like tractors, harvesters, and sprayers. These machines require robust and lightweight materials to ensure optimal performance and fuel efficiency. Special steel grades provide the necessary strength while keeping the weight of the equipment low, allowing farmers to cover larger areas and increase productivity. Additionally, special steel alloys are used in the production of precision tools, such as cutting blades and drill bits, used in precision farming techniques. These tools enable farmers to perform tasks with high accuracy, such as soil sampling, seeding, and crop monitoring. The durability and sharpness of special steel tools enhance the precision and effectiveness of these operations, leading to improved crop yields and resource utilization. Moreover, special steel is also employed in the construction of infrastructure related to the agriculture aftermarket industry. For example, steel beams and columns are used in the fabrication of storage facilities, barns, and grain silos, providing structural strength and stability. This infrastructure allows for efficient storage, handling, and transportation of agricultural products, contributing to the overall efficiency of the industry. In conclusion, special steel is an essential component in the agriculture aftermarket industry as it contributes to the production of durable machinery parts, lightweight equipment, precision tools, and robust infrastructure. By offering enhanced strength, durability, and corrosion resistance, special steel helps farmers improve productivity, reduce downtime and maintenance costs, and achieve better crop yields.

Send your message to us

Grade ASTM A36 Carbon Steel Round Bar Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords