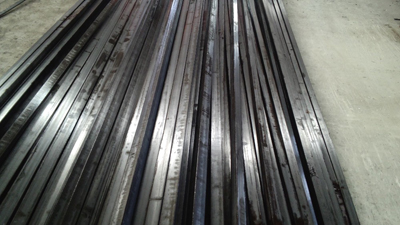

Stainless Steel Square Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 tons/month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

the Stainless Steel Square Bar is hot rolled, range from 5mm to 100mm,

Grade: Q195 Q235 and equivalent.

the monthly production capacity can be 500-1000 tons

it is used as structure steel.

the MOQ is usually 50 tons

canbe delivered by bulk vessel or by container.

- Q: How accurate are steel squares for measuring angles?

- Steel squares, renowned for their precision and adherence to strict standards, offer exceptional accuracy in angle measurement. Nevertheless, external factors like wear and tear, misuse, or manufacturing defects may impact their precision. Thus, regular checks and calibrations are crucial to uphold their accuracy. All in all, when utilized correctly and maintained diligently, steel squares prove themselves as highly reliable instruments for measuring angles.

- Q: Can a steel square be used for checking the alignment of a belt sander table?

- Yes, a steel square can be used for checking the alignment of a belt sander table. The square's straight edge can be placed against the table and used to ensure that it is perfectly parallel to the belt sander's direction of movement. This method helps to ensure accurate and precise sanding results.

- Q: Can a steel square be used for measuring and marking rip cuts?

- Yes, a steel square can be used for measuring and marking rip cuts. A steel square is a versatile and reliable tool commonly used in woodworking and construction. It has a long arm and a shorter arm that meet at a 90-degree angle, allowing for precise measurements and markings. When used for rip cuts, the long arm of the steel square can be held against the edge of the material being cut, ensuring a straight and accurate line. The shorter arm can be used to mark the desired width of the rip cut, providing a clear guide for the saw or cutting tool. Overall, a steel square is a valuable tool for measuring and marking rip cuts, providing accuracy and consistency in woodworking projects.

- Q: What is the difference between a framing square and a try square?

- A framing square and a try square are both types of square tools used in woodworking and construction, but they have some key differences in their design and purpose. A framing square, also known as a carpenter's square or steel square, is a larger and more versatile tool. It typically has a longer blade, usually around 24 inches, and a shorter tongue or handle, which is usually around 16 inches. The blade and tongue are joined at a 90-degree angle, forming an L-shape. This design allows the framing square to be used for a variety of tasks, such as laying out and marking right angles, checking the squareness of structures, measuring angles, and making complex calculations in carpentry and framing work. On the other hand, a try square is a smaller and more compact tool. It consists of a short blade, usually around 6 to 12 inches, and a shorter handle, typically around 3 to 6 inches. The blade and handle are also joined at a 90-degree angle, forming an L-shape similar to the framing square. However, the try square is primarily used for checking and marking right angles, ensuring the accuracy and squareness of joints, and making precise measurements in woodworking projects, such as marking and cutting 90-degree angles on boards or checking the squareness of edges and corners. In summary, the main difference between a framing square and a try square lies in their size, versatility, and intended use. A framing square is larger, more versatile, and used for a wide range of tasks in carpentry and construction, while a try square is smaller, more compact, and primarily used for checking and marking right angles in woodworking projects.

- Q: How do you use a steel square to check for levelness in a floor?

- To use a steel square to check for levelness in a floor, you would first place the square on the floor at different locations. Then, you would observe if there are any gaps between the square and the floor surface. If there are no gaps, it indicates that the floor is level. However, if there are gaps, it suggests that the floor is not level and may require further inspection or adjustments.

- Q: What is the purpose of a steel square?

- The purpose of a steel square is to provide a versatile and accurate measuring tool for various carpentry and woodworking tasks. It helps in measuring and marking right angles, laying out angles, and determining lengths and widths of materials.

- Q: Can a steel square be used for measuring roof pitch?

- Yes, a steel square can be used for measuring roof pitch. A steel square, also known as a framing square or carpenter's square, is a versatile tool used in carpentry and construction. It has a long blade and a shorter tongue, forming an L-shape. The blade of the square is marked with various angles and measurements, making it useful for determining roof pitch. To measure the roof pitch using a steel square, you can place the longer blade of the square along the roof rafters or trusses, ensuring that it is aligned with the bottom edge of the roof. Then, you can adjust the angle of the square until the shorter tongue rests on the roof surface. By reading the measurement on the blade where it intersects the desired pitch, you can determine the roof pitch accurately. The steel square's ability to measure angles and pitch makes it a reliable tool for determining roof slope and ensuring proper installation of roofing materials. However, it is essential to note that using a steel square may require some knowledge and practice to obtain accurate measurements. Additionally, other specialized tools, such as a digital inclinometer or a laser level, may provide more precise measurements for roof pitch in certain circumstances.

- Q: How do you use a steel square to lay out a pyramid shape?

- In order to lay out a pyramid shape, it is necessary to follow a few steps using a steel square. The steel square is a triangular measuring tool with different angles marked on each side, and it is important to have one before beginning the process. To start, the desired base length of the pyramid must be determined. Let's assume a base of 10 feet is desired. 1. Position the steel square on a flat surface, ensuring that the long side, known as the blade, is facing towards you. 2. Measure and indicate a point that is 10 feet away from the bottom corner of the blade, which will serve as the base length. 3. Proceed to measure and mark a point that is 10 feet along the blade, starting from the base length mark made in the previous step. This will establish the height of the pyramid. 4. In order to find the center point of the base, measure and mark the midpoint between the two base length marks. 5. Use a straightedge or ruler to connect the center point with each of the base length marks. This will form the base of the pyramid. 6. Subsequently, connect the center point with the top point that was marked for the height. This will create the sides of the pyramid. 7. Repeat steps 1-6 on the opposite side of the steel square to finalize the pyramid shape. By utilizing the steel square, one can ensure the accuracy of all angles and measurements, enabling the precise laying out of a pyramid shape.

- Q: How do you determine the squareness of a steel square?

- To determine the squareness of a steel square, there are several methods you can follow: 1. Check the edges: Start by inspecting the edges of the steel square. Ensure that they are straight, without any bends or warping. If the edges are not straight, it may affect the squareness of the tool. 2. Measure diagonally: Take a measurement from one corner of the steel square to the opposite corner. Then, measure the other diagonal. The two measurements should be equal if the square is perfectly square. If they differ, note the difference as it indicates the deviation from squareness. 3. Utilize a try square: A try square is a specialized tool designed specifically for checking squareness. Place the steel square against the straight edge of the try square, ensuring that both tools are aligned properly. Verify that the edges are parallel and check if the corners of the steel square align perfectly within the try square. 4. Verify right angles: Place the steel square against a flat surface, such as a table or workbench, ensuring that it is fully touching the surface. Use a known square object, like a piece of wood with a verified right angle, to check the squareness. Align the object against one side of the square, then slide it along the adjacent side. If the object remains in contact with both sides without any gaps or overlaps, it indicates a square angle. 5. Use a precision square: A precision square is a highly accurate tool specifically designed for checking squareness. Place the steel square against the flat surface of the precision square, ensuring that both tools are in full contact. Check if the edges and corners align perfectly, indicating squareness. Remember, the accuracy of the determination will depend on the precision of the measuring tools and the quality of the steel square itself. It is advisable to use multiple methods and tools to cross-verify the squareness of the steel square for more accurate results.

- Q: How do you use a steel square for determining the center of a circle?

- To determine the center of a circle using a steel square, follow these steps: 1. Place the steel square on the edge of the circle, ensuring it intersects the center. Draw a straight line across the diameter of the circle. 2. Mark the points where the straight line intersects the circle on both sides. These marks will be your reference points. 3. Rotate the steel square and align one of its edges with one of the reference points. 4. Draw a second straight line across the diameter, intersecting the center and the other reference point. 5. The intersection of the two lines is the center of the circle. You can either mark this point or use it as a reference for further measurements or constructions. By using a steel square to determine the center of a circle, you can achieve precise and accurate measurements, ensuring consistency and reliability.

STEXIN, an enterprise specializing in the production and sales of square bar, round bar and flat bar. The annual production capacity of square billet is 60,000 mtons, and sturtual steel 80,000 mtons.

1. Manufacturer Overview

| Location | Renqiu, China |

| Year Established | 1996 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | Mid East; Southeast Aisa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 70,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Square Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 tons/month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords