China Made Extruded Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium Profile

Our advantages:

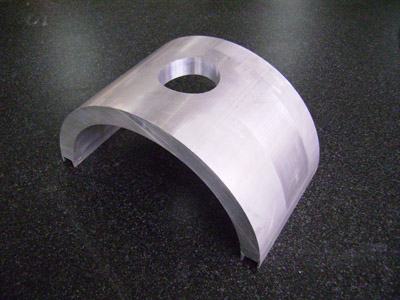

1)we can provide"one- stop service from melting,extruding,surface treatment,machining,welding,assembling to mould design & building.

2)we have a good capacity of precise machining,cnc machining.

3)we can provide good quality with reasonable price.

Products:

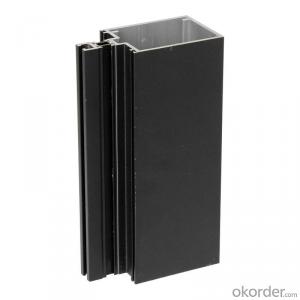

Description | Aluminium Profiles |

Alloy | Al 6063 T5 /T6 or 6061 or 6005 or as per customers' need |

Finish | Anodizing or powder coating with various colors |

Packing | Foam sheet,poly bag,plastic bag,carton |

Brand | YMJ |

Original place | |

Certificate | ISO9001 |

Equipments:

7extruders,2 six meters long anodizing lines,1 twelve meters long anodizing line(including dyeing & electrolysis).1 powder coating line,5 melting lines,12 CNCs(including 2 machines which can mill 6.5m long profile),10 argon arc welding machines and multiple machines for cutting,drilling,punching,milling,shearing and bending,2 spectrum scanners,1 projective instument,1 extension test machine,1 mechanical property tester,1 Rohs tester and 1 metallurgical microscope.

Service:

We're a well- established manufacture for aluminium products,we're confident we can give our customers complete satisfication.

We can provide good quality with reasonable price.

- Q: How can the aluminum profile T6 and T5 be distinguished?

- Mechanical properties are inconsistent, T5 tensile strength is 160 MPa; T6 tensile strength is 215 mpa. (normally determined by this method) do a tensile test and you'll see

- Q: Can aluminum profiles be used for curtain wall systems?

- Yes, aluminum profiles can be used for curtain wall systems. Aluminum is a popular material choice for curtain walls due to its lightweight, durability, and flexibility in design. It offers excellent structural integrity, weather resistance, and thermal performance, making it suitable for creating large glazed facades in buildings. Additionally, aluminum profiles can be easily fabricated, allowing for customization and integration of various components in curtain wall systems.

- Q: How do aluminum profiles provide structural stability?

- Aluminum profiles provide structural stability through their inherent properties such as high strength-to-weight ratio and excellent corrosion resistance. These profiles are designed to distribute and withstand loads efficiently, ensuring the structural integrity of various applications. Additionally, their versatility allows for customization and integration with other materials, further enhancing stability in different environments and industries.

- Q: What are the different methods of joining aluminum profiles together?

- There are various ways to connect aluminum profiles, depending on the desired result and specific application. The most commonly used techniques include: 1. Mechanical fastening: To secure aluminum profiles, screws, bolts, or rivets can be employed. This method is straightforward and cost-effective, suitable for different applications. However, it may leave visible fasteners and require additional finishing. 2. Welding: Aluminum profiles can be joined using different welding techniques like TIG, MIG, or laser welding. Welding creates a sturdy and seamless joint, making it ideal for structural purposes. However, it demands specialized equipment and expertise. 3. Adhesive bonding: Specialized adhesives for aluminum bonding can be utilized to connect profiles. This technique offers high strength, even stress distribution, and a clean appearance. Adhesive bonding is commonly used for lightweight applications or when welding is not feasible. 4. Slotting and interlocking: Profiles with specially designed slots or interlocking features can be connected without additional hardware. This method ensures a seamless and neat appearance while maintaining structural integrity. 5. Thermal joining: Heat-based methods like hot plate welding or induction heating can be employed to connect aluminum profiles. These processes involve melting a portion of the aluminum surface and bonding it upon cooling. Thermal joining provides both strength and aesthetics without requiring extra materials. 6. Extrusion-based connectors: Connectors designed for extrusion are components that allow for the joining of aluminum profiles. These connectors are typically inserted into the slots or channels of the profiles, providing a secure and long-lasting connection. When choosing the appropriate method for joining aluminum profiles, it is necessary to consider factors such as strength requirements, appearance, ease of assembly, and cost. Each method has its own advantages and limitations, so the most suitable technique depends on the specific application and desired outcome.

- Q: Explain the various methods used to install aluminum profiles in construction projects.

- <p>There are several methods to install aluminum profiles in construction: 1. Bolting: Aluminum profiles can be secured with bolts and nuts, providing a strong and adjustable connection. 2. Welding: For permanent and rigid connections, aluminum profiles can be welded together. 3. Adhesive bonding: Using specialized adhesives, aluminum profiles can be bonded together for a secure fit. 4. Clipping: Some profiles come with clip-on connectors that allow for quick and easy assembly. 5. Screwing: Self-tapping screws can be used to join aluminum profiles, providing a strong hold without the need for pre-drilled holes. 6. Mortise and tenon: A traditional woodworking joint that can be adapted for aluminum profiles, creating a tight and secure fit. Each method has its advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: How are aluminum profiles cut and shaped?

- Depending on the desired result, there are various methods available for cutting and shaping aluminum profiles. One popular approach involves the use of saws. Whether it's a hand saw or a power saw like a miter saw or circular saw, specially designed blades capable of cutting through aluminum are utilized. Alternatively, CNC (Computer Numerical Control) machines provide a highly precise option. By programming these machines, aluminum profiles can be cut and shaped with great accuracy. This technique is particularly suitable for intricate and complex designs. Shaping aluminum profiles can be achieved through different techniques as well. For instance, bending is a common method. Specialized bending machines apply force gradually to achieve the desired angle without causing any damage or deformation to the aluminum. Another shaping technique is extrusion. This involves forcing the aluminum through a die to create a specific shape. Extrusion is commonly employed in the manufacturing of aluminum profiles with consistent cross-sectional shapes like tubes or beams. Overall, achieving the desired results in cutting and shaping aluminum profiles necessitates the use of specialized tools and machinery. The specific method chosen depends on the complexity of the design and the desired outcome.

- Q: Are aluminum profiles compatible with other materials for construction purposes?

- <p>Yes, aluminum profiles can be used in combination with other materials in construction. They are often paired with steel, glass, and various plastics due to their lightweight, durability, and corrosion resistance. Aluminum's ability to be easily joined and its compatibility with different finishes make it a versatile choice for construction projects.</p>

- Q: Are aluminum profiles suitable for electrical grounding applications?

- Indeed, electrical grounding applications find aluminum profiles to be a fitting choice. The high conductivity of aluminum enables it to proficiently transport electrical currents and disperse any conceivable electrical charges. In the realm of electrical grounding systems, aluminum profiles are frequently employed for grounding bars, busbars, and grounding conductors. They offer a dependable and long-lasting solution for establishing a low-resistance pathway, ensuring the secure flow of electrical currents towards the ground. Moreover, the exceptional corrosion resistance properties of aluminum profiles enhance their aptness for grounding applications, whether indoors or outdoors.

- Q: What are the different bending machines or tools used for aluminum profiles?

- There are several bending machines and tools that are commonly used for aluminum profiles. These tools are designed to manipulate aluminum profiles into various shapes and angles to meet specific project requirements. 1. Manual Tube Bender: This is a hand-operated bending tool that is commonly used for smaller aluminum profiles. It consists of a lever and a bending shoe that is used to bend the profile manually. 2. Hydraulic Tube Bender: This machine is equipped with hydraulic power to bend larger and thicker aluminum profiles. It offers more precision and control compared to manual benders, making it suitable for industrial applications. 3. CNC Tube Bending Machine: This is a computer-controlled machine that uses a combination of hydraulic power and computer programming to accurately bend aluminum profiles. It can produce complex and precise bends, making it ideal for high-volume production and intricate designs. 4. Roll Bending Machine: This machine is specifically designed for bending aluminum profiles into curved shapes. It consists of three rolls, with the profile passing through the middle roll while the other two rolls apply pressure to bend it into the desired curve. 5. Mandrel Bender: This tool is used for bending aluminum profiles without deforming or collapsing the inner diameter. It uses a mandrel (a rod inserted into the profile) to support the inner wall during the bending process, ensuring a smooth and consistent bend. 6. Rotary Draw Bender: This machine uses a combination of bending dies and a rotating arm to produce accurate and repeatable bends in aluminum profiles. It is commonly used for bending tubes and pipes, but can also be adapted for aluminum profiles. These bending machines and tools offer different levels of precision, control, and production capacity, allowing manufacturers and fabricators to choose the most suitable option based on their specific needs and requirements.

- Q: This question asks if aluminum profiles can be utilized in the construction of environmentally friendly buildings.

- <p>Yes, aluminum profiles can be used for green building applications. They are valued for their durability, recyclability, and energy efficiency. Aluminum is lightweight, which reduces the building's carbon footprint during transportation. It also has excellent thermal conductivity, allowing for better insulation and energy conservation. Additionally, aluminum can be recycled without losing its properties, contributing to a circular economy and reducing waste. These characteristics make aluminum profiles suitable for sustainable construction practices.</p>

Send your message to us

China Made Extruded Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords