Customized Extruded Aluminum Profiles for Marine Ship Deck Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium Profile for Marine Ship Deck Making Description

Aluminium Profile for Marine Ship Deck Making is one semi-finished aluminium material. The alloy AA5083 T6 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Profile for Marine Ship Deck Making

Aluminum Extrusion | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Profile for Marine Ship Deck Making

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Profile for Marine Ship Deck Making

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Profile for Marine Ship Deck Making

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

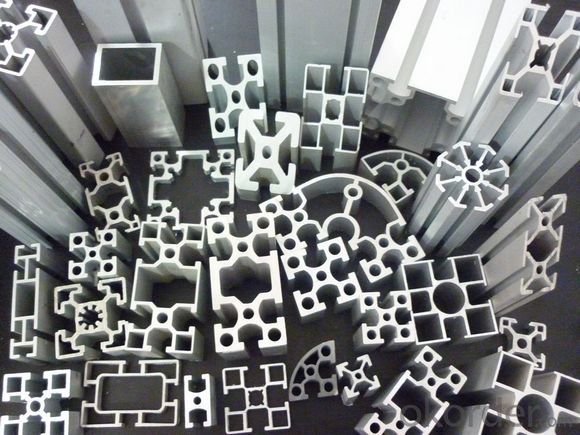

6. Image of Aluminium Profile for Marine Ship Deck Making

7. Package and shipping of Aluminium Profile for Marine Ship Deck Making

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to utilize aluminum profiles in interior design projects?

- <p>Yes, aluminum profiles can be used for interior design. They are popular for their strength, durability, and modern aesthetic. Aluminum profiles are lightweight, easy to install, and resistant to corrosion, making them suitable for various applications such as window frames, door frames, shelving systems, and decorative elements. They can be powder-coated or anodized to achieve different colors and finishes, allowing for a wide range of design flexibility.</p>

- Q: Are aluminum profiles suitable for partition walls?

- Partition walls can indeed be constructed using aluminum profiles. Aluminum, a material known for its lightweight and durability, is frequently utilized in the construction industry because of its versatility and strength. It offers exceptional structural support and can be easily tailored to meet diverse design specifications. Moreover, aluminum profiles provide a sleek and contemporary appearance, rendering them highly sought after for modern interior designs. Furthermore, aluminum is resistant to corrosion and necessitates minimal upkeep, making it a cost-effective alternative for partition walls. In conclusion, aluminum profiles are a dependable and pragmatic option for producing robust and visually appealing partition walls.

- Q: Is it feasible to recycle aluminum profiles economically and in significant quantities?

- <p>Yes, aluminum profiles can be recycled at a reasonable cost and volume. Recycling aluminum is more cost-effective than mining and refining new aluminum from bauxite. The process requires less energy, which reduces costs. Additionally, aluminum has a high recycling rate, with about 75% of all aluminum ever produced still in use today. This indicates that aluminum recycling is both economically viable and can be done in significant volumes, contributing to sustainability and waste reduction.</p>

- Q: What are the different surface texturing options for aluminum profiles?

- There are several surface texturing options available for aluminum profiles, each offering unique benefits and aesthetic appeal. Some of the common surface texturing options for aluminum profiles include: 1. Brushing or Satin Finishing: This technique involves the use of abrasive brushes to create a linear or circular pattern on the surface of the aluminum profile. It provides a smooth, matte finish, which is visually appealing and hides minor imperfections. 2. Anodizing: Anodizing is a popular surface treatment method that involves creating an oxide layer on the aluminum surface. This process not only enhances the corrosion resistance of the profile but also allows for the application of various colors, making it an excellent choice for decorative applications. 3. Polishing: Polishing is a process that involves mechanically smoothing the surface of the aluminum profile to achieve a reflective finish. This technique is commonly used in architectural applications where a high-gloss appearance is desired. 4. Powder Coating: Powder coating is a durable and versatile surface treatment option for aluminum profiles. A dry powder is electrostatically applied to the profile, and then it is cured under heat, creating a protective and decorative coating. Powder coating provides a wide range of color options and excellent resistance to weathering, making it suitable for both interior and exterior applications. 5. Textured Coating: Textured coating is a specialized powder coating technique that offers a unique texture and appearance to the aluminum profile. It can mimic various textures, such as wood grain or stone, adding a distinctive look to the profile. 6. Chemical Etching: Chemical etching is a process that involves selectively removing material from the surface of the aluminum profile using chemical solutions. This technique can create intricate patterns or designs on the surface, making it ideal for decorative or branding purposes. 7. Laser Engraving: Laser engraving is a precise and versatile method for creating patterns, logos, or text on the surface of aluminum profiles. The laser beam removes the material, leaving a permanent mark on the profile. Laser engraving offers high precision and customization options, making it suitable for branding and personalization. These are just a few examples of the surface texturing options available for aluminum profiles. The choice of texturing method depends on the desired appearance, functionality, and application of the profile.

- Q: How are aluminum profiles cut and shaped?

- Aluminum profiles are cut and shaped using various methods such as sawing, milling, drilling, and bending. Sawing is the most common method, where a circular saw or bandsaw is used to cut the aluminum profiles to the desired length. Milling involves removing excess material using a rotating cutting tool to create specific shapes and designs. Drilling is used to create holes in the profiles using a drill bit. Lastly, bending is employed to shape the profiles by applying force to bend them into the desired angles or curves.

- Q: Is it possible to utilize aluminum profiles as a material for flooring?

- <p>Yes, aluminum profiles can be used for flooring, particularly in industrial or commercial settings where durability and resistance to wear are required. They are known for their strength, lightweight, and corrosion resistance, making them suitable for high-traffic areas. Aluminum profiles can be used to create grid systems or as support structures for modular flooring solutions. However, they are not typically used as the direct surface material for flooring due to their hardness and potential for thermal conductivity, which can make them uncomfortable underfoot. Instead, they are often part of a system that supports other flooring materials like tiles or planks.</p>

- Q: How much is the 60 series aluminum frame bridge standard size, how much is the size of the fan

- [60] galuminium Qianjin aluminum series insulating aluminum window size 60x53.5, window size 67.8x68.6.

- Q: This question asks for a comparison between aluminum profiles and other building materials regarding their cost and performance.

- <p>Aluminum profiles are often more cost-effective than materials like steel or wood in the long run due to their durability and low maintenance requirements. They offer high strength-to-weight ratios, making them ideal for structures where weight is a concern. Additionally, aluminum profiles have excellent resistance to corrosion and weathering, which reduces the need for repainting or replacement over time. They are also energy-efficient, as they can help in reducing heat transfer, thus lowering energy costs for heating and cooling. However, the initial cost of aluminum profiles can be higher than some alternatives, but their long-term performance and low maintenance can offset this initial expense.</p>

- Q: Are aluminum profiles suitable for use in exterior wall insulation systems?

- <p>Yes, aluminum profiles can be used for exterior wall insulation systems. They are known for their durability, resistance to corrosion, and ability to withstand various weather conditions. Aluminum profiles provide a strong structural framework that can support insulation materials effectively. They are also lightweight, which makes them easy to handle and install. Additionally, aluminum profiles can be anodized or coated to enhance their resistance to environmental factors, making them a popular choice for exterior insulation systems.</p>

- Q: Are aluminum profiles suitable for balcony railings?

- Indeed, balcony railings can be effectively made using aluminum profiles. Aluminum is a favored material for balcony railings because it possesses qualities such as resilience, robustness, and minimal upkeep requirements. Its resistance to rust and corrosion makes it exceedingly appropriate for outdoor applications. Moreover, aluminum profiles can be effortlessly tailored and molded to match any desired design or architectural style. Although lightweight, they offer ample strength to ensure necessary support and safety for balcony railings. Additionally, aluminum railings are obtainable in a plethora of finishes and colors, providing limitless possibilities for design. On the whole, aluminum profiles are a dependable and fashionable choice for balcony railings.

Send your message to us

Customized Extruded Aluminum Profiles for Marine Ship Deck Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords