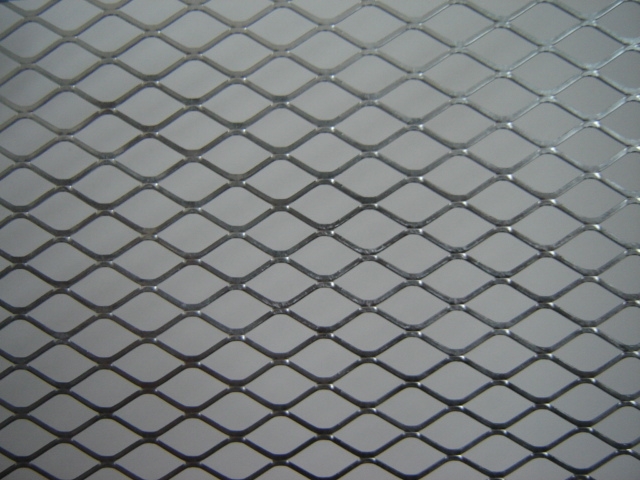

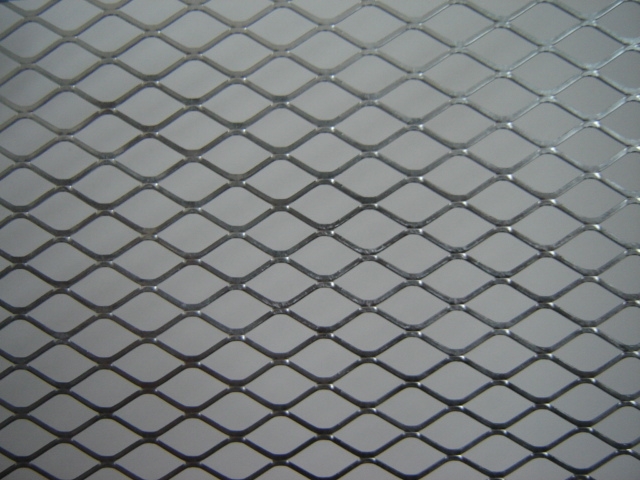

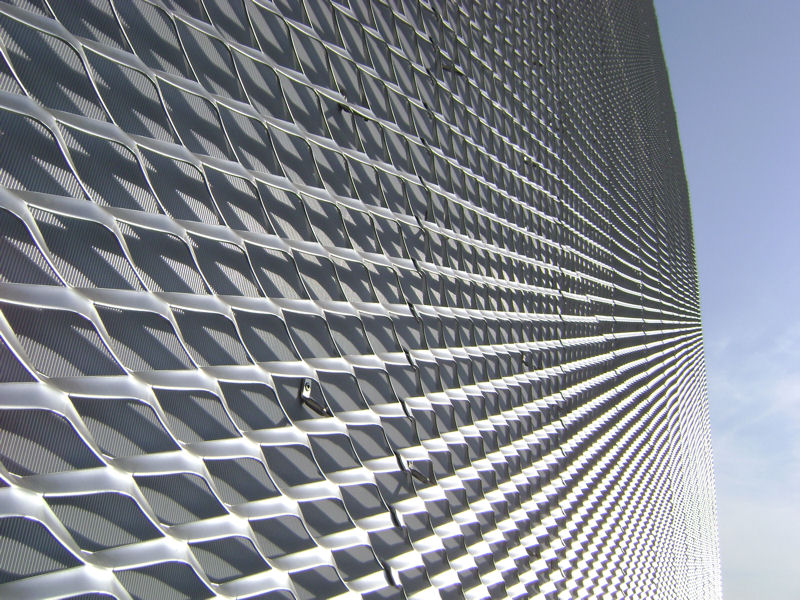

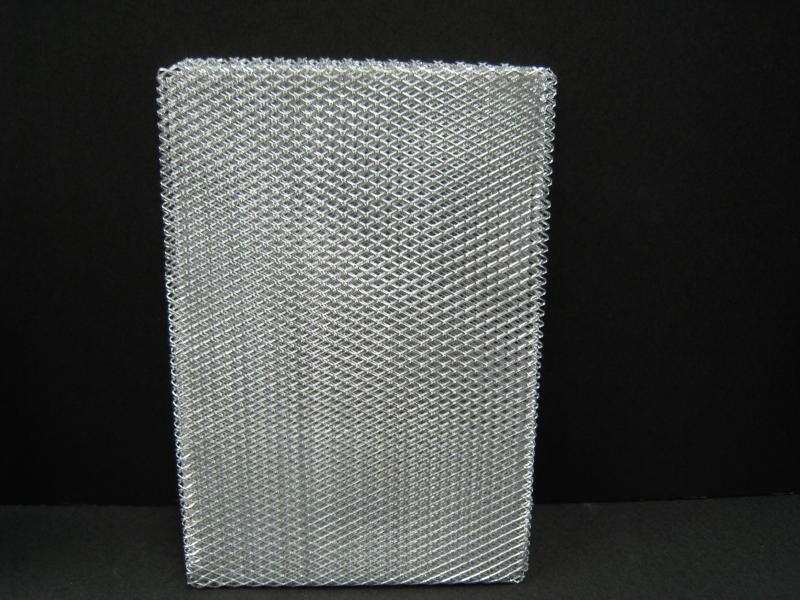

Aluminum Expanded Metal Mesh

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

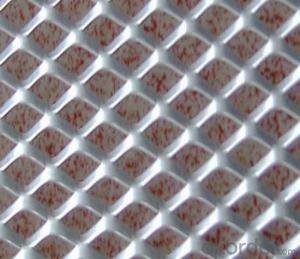

Material: aluminum(alloy)plate

Thickness: 0.3-8.0mm

Hole Shape: diamond

LWM: 3.0-100mm

SWM: 2.0-80mm

Strand Width: 0.3-8.0mm

Strand Thickness: up to 8.0mm

Mesh Width: 0.3-1.2mm

Roll Length: 1-30m/roll

Surface: not treated,PVC coated , Galvanized

Certification: ISO9001:2008

Use: Widely used in the agriculture, construction, medicine, filtering, paper-making, handicraft -making et

Packing Detailes: Packed with waterproof paper and paper boxes or according to every customer's requirement.

Delivery Time:15 days after receiving your deposit

Payment terms:

1. 30% T/T in advance, 70% payable against the copy of the B/L.

2. L/C is also acceptable.

3. As per your special requirements which are also welcome to discuss.

- Q: Can steel wire mesh be used for elevator interiors?

- Indeed, elevator interiors can benefit from the utilization of steel wire mesh. This adaptable and robust material possesses the ability to bestow a contemporary and visually pleasing appearance upon elevator interiors. It offers the potential for the creation of embellished panels, divisions, or even comprehensive wall coverings. The mesh can be tailored to various designs, dimensions, and finishes, accommodating the precise specifications of the elevator interior's design. Furthermore, the convenience of cleaning and maintaining steel wire mesh makes it a sensible selection for elevator interiors that necessitate frequent upkeep.

- Q: How strong is steel wire mesh?

- Known for its exceptional strength and durability, steel wire mesh varies in specific strength depending on factors such as wire diameter, thickness, steel type, and mesh size. Nevertheless, steel wire mesh is incredibly strong, capable of withstanding heavy loads and high tension. In construction, engineering, and industrial applications, steel wire mesh is commonly utilized due to its crucial strength. It provides reinforcement for concrete structures, enhancing strength and stability. Moreover, its ability to resist impact and external forces makes it a popular choice for fencing. Thanks to its high tensile strength, steel wire mesh can endure significant pressure and stress without deforming or breaking. This quality makes it ideal for applications requiring a durable and long-lasting solution. It can withstand heavy loads, resist stretching, and retain its structural integrity even in extreme conditions. In summary, steel wire mesh is renowned for its strength, making it a reliable option for applications prioritizing durability and stability. Its strength and resilience make it an excellent choice for reinforcement, fencing, and other demanding uses.

- Q: How is steel wire mesh used in reinforcement of airports and transportation hubs?

- Steel wire mesh is commonly used in the reinforcement of airports and transportation hubs to enhance the structural integrity of concrete structures such as runways, taxiways, and pavements. By adding steel wire mesh to the concrete mixture, it provides increased strength and durability, allowing the infrastructure to withstand heavy loads, frequent traffic, and extreme weather conditions. This reinforcement technique helps prevent cracking and deterioration, ensuring the safety and longevity of the airport and transportation hub facilities.

- Q: Can steel wire mesh be used for industrial shelving?

- Yes, steel wire mesh can be used for industrial shelving. Steel wire mesh is a strong and durable material that is commonly used in various industrial applications, including shelving systems. It offers several advantages, such as excellent ventilation, visibility, and easy maintenance. The open design of wire mesh allows for better airflow, making it suitable for storing items that require ventilation or cooling. Additionally, the visibility provided by the mesh allows for easy identification and access to stored items. The strength and durability of steel wire mesh make it capable of withstanding heavy loads, making it ideal for industrial shelving where heavy items or equipment need to be stored. Furthermore, steel wire mesh is resistant to corrosion, which is essential in industrial environments where exposure to moisture or chemicals is common. Overall, steel wire mesh is a practical and reliable choice for industrial shelving, providing strength, durability, ventilation, visibility, and low maintenance requirements.

- Q: How does the mesh opening size affect the performance of steel wire mesh?

- The mesh opening size of steel wire mesh directly affects its performance. A smaller mesh opening size provides higher structural integrity and better support, making it suitable for applications that require strong and durable mesh, such as fencing or reinforcing concrete. On the other hand, a larger mesh opening size allows for increased visibility and airflow, making it more suitable for applications that prioritize ventilation or visibility, such as window screens or filtration systems. Ultimately, the mesh opening size should be chosen based on the specific requirements and intended use of the steel wire mesh.

- Q: What are the benefits of using steel wire mesh in the mining industry?

- One of the main benefits of using steel wire mesh in the mining industry is its high strength and durability. Steel wire mesh is able to withstand heavy loads and harsh conditions, making it ideal for use in mining operations. Additionally, steel wire mesh is resistant to corrosion, which is crucial in environments where moisture and chemicals are present. It also provides excellent visibility and ventilation, ensuring the safety and well-being of workers. Overall, steel wire mesh enhances operational efficiency, promotes safety, and reduces maintenance and replacement costs in the mining industry.

- Q: What are the applications of steel wire mesh?

- Steel wire mesh has a wide range of applications due to its strength, durability, and versatility. Some of the key applications of steel wire mesh include: 1. Construction industry: Steel wire mesh is extensively used in construction projects for reinforcing concrete structures such as walls, floors, and foundations. It helps to enhance the structural integrity and prevent cracking or collapsing. 2. Industrial manufacturing: Steel wire mesh is used in the manufacturing industry for various purposes such as filtration, separation, and reinforcement. It is commonly employed in machines, equipment, and conveyor belts to ensure optimal performance and durability. 3. Security and safety: Steel wire mesh is widely used for security purposes, such as fencing and enclosures, to create barriers that provide protection against intruders or unauthorized entry. It is also used in window screens, door grilles, and animal enclosures to ensure safety while allowing ventilation and visibility. 4. Agriculture and farming: Steel wire mesh is commonly used in the agriculture and farming industry for applications such as animal fencing, poultry cages, and crop protection. It helps to keep animals secure, prevent pests from damaging crops, and create controlled environments for livestock. 5. Decorative and architectural: Steel wire mesh is often used in interior and exterior design applications for its aesthetic appeal. It can be utilized in decorative panels, artistic installations, furniture, and sculptures to create visually appealing and unique designs. 6. Automotive and transportation: Steel wire mesh is used in the automotive industry for various applications such as vehicle grilles, radiator guards, and air filters. It provides protection against debris and enhances airflow for cooling systems. 7. Mining and quarrying: Steel wire mesh is extensively used in mining and quarrying operations for safety purposes. It is commonly employed as a protective barrier to prevent rockfalls and ensure worker safety in underground mines and open pit quarries. 8. Environmental applications: Steel wire mesh is utilized in environmental applications such as erosion control, slope stabilization, and shoreline protection. It helps to prevent soil erosion, retain sediments, and mitigate the impact of natural elements. Overall, the applications of steel wire mesh are diverse and span across various industries, making it an essential material for a multitude of purposes.

- Q: Can steel wire mesh be used for decorative purposes?

- Yes, steel wire mesh can be used for decorative purposes. It offers a unique and modern look that can be incorporated into various architectural and interior design elements. Whether it is used to create stylish room dividers, decorative wall panels, or unique lighting fixtures, steel wire mesh adds an industrial and contemporary touch to any space. Additionally, its durability and strength make it suitable for both indoor and outdoor decorative applications.

- Q: What is the maximum temperature that steel wire mesh can withstand?

- The maximum temperature that steel wire mesh can withstand depends on the specific type of steel used and the manufacturing process. Generally, stainless steel wire mesh can withstand temperatures up to 1000°C (1832°F), while carbon steel wire mesh typically has a lower maximum temperature tolerance of around 550°C (1022°F). However, it is important to consult the manufacturer or specific product specifications for accurate information on the maximum temperature resistance of a particular steel wire mesh.

- Q: How does steel wire mesh perform in terms of visibility and transparency?

- Due to its dense construction and solid structure, steel wire mesh is generally characterized by low visibility and transparency. The interweaving of steel wires forms a solid barrier that hinders the view and restricts the passage of light. This lack of transparency makes it ideal for situations where privacy and security are of utmost importance, including fencing, partitions, and window screens. However, if the objective is to optimize visibility or enable abundant natural light to pass through, alternative materials such as glass or transparent plastics would be more appropriate choices.

Send your message to us

Aluminum Expanded Metal Mesh

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords