Oneup Aluminum Bars - AA1070 C.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1070 C.C Mill Finished Aluminum Circles used for Cookware Description

AA1070 C.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1070 C.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1070 C.C Mill Finished Aluminum Circles used for Cookware

1)Surface Quality : be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

2)Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3)Fine craftsmanship

4)Durable

5)Easy processing

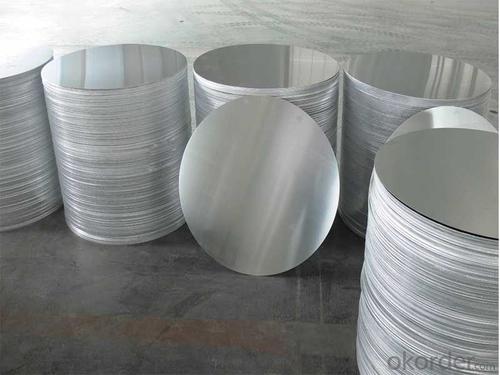

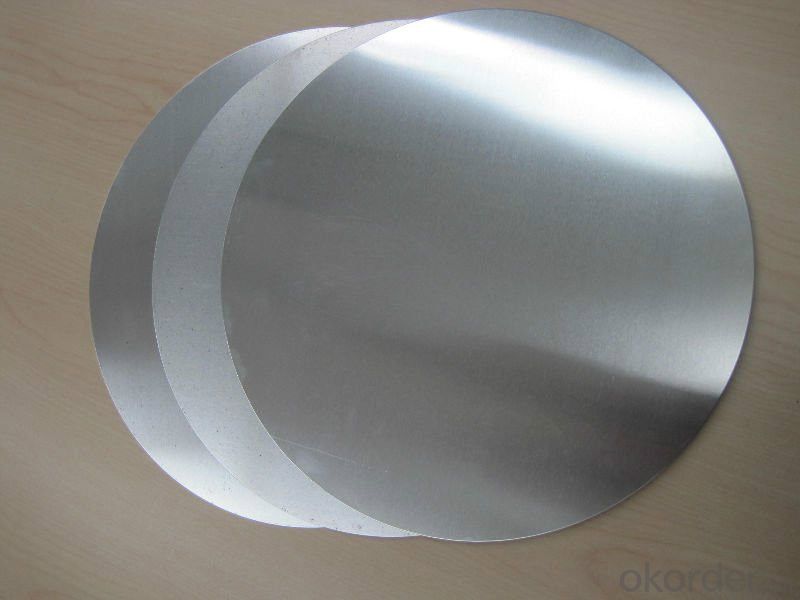

3.AA1070 C.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1070 C.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1070 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1070 C.C Mill Finished Aluminum Circles used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

- Q: Which of the 6061 aluminum bars, heat treated and 7075 aluminum rods, has been treated with heat?

- The hardness of aluminum alloys is directly related to the chemical composition of the alloy.

- Q: What are the differences between aluminum bars 5052 and 6063?

- 5052 aluminum alloy density: 2.68g/cm3; 6063 aluminum alloy density: 2.71g/cm3. aluminum alloy casting and extrusion form density is different, extrusion aluminum alloy density is higher.

- Q: What I do is export, and like this, the tax check will be checked every time. Is there a better export HS code that meets the product characteristics?

- You should be the best choice, there is no special regulatory conditions, especially including the name of the aluminum bar.You choose the number, if it is imported, the tariff rate of 15% ah.

- Q: What are the elements of the national standard aluminum rod 6063t5?

- chemical compositionAluminum Al: marginSilicon Si:0.20 ~ 0.60Copper Cu:0.10Magnesium Mg:0.45 ~ 0.9Zinc Zn:0.10Manganese Mn:0.10Titanium Ti:0.10Chromium Cr:0.10Iron Fe:0.35Single: 0.05 total: 0.15

- Q: Which wear resistant die casting aluminum and aluminum bars?

- These two processes are not very different, mainly depends on the alloy composition, the general choice of aluminum is because of good corrosion resistance and small proportion of aluminum.

- Q: Automatic blanking (formerly under copper machine)

- The ordinary copper can be cut, Dongguan Shenghui machinery limited company for your service.

- Q: What is the cause of the center crack in the casting of aluminum bars?

- 4. pouring temperature is too high5. casting out the casting prematurely6. heat treatment, overheating or over burning, excessive cooling rate

- Q: What grade of aluminum rod can be machined to teach high surface finish?

- I think no aluminum rod can be said produced higher smoothness, because will be machined out of aluminum oxidation in the air so that the finish grade did not say out of aluminum rod processing would have been good, all aluminum rods are the same as long as the feed and speed the car out of the car with the pin depth finish is very good. I think 6061-T1 made a very bright finish of our company is to use a medium grade finish up to 2

- Q: What are the diameters of the aluminum bars sold on the market?

- On the market, the general aluminum rod diameter 5, 6, 8, 10, 12, 15, 18, 20mm, 25, 30~95, 100mm (5mm interval), 100~200 (10mm interval), basically extrusion aluminum rod.Then, more than 200mm is basically a cast aluminum bar.The tube can also be made of aluminium tube, the price is almost the same as the aluminum bar, and the right size can be saved.

- Q: Is it 76012000, 76042900 or 7604291010? Thank you very much! Urgently!! FiveIs it 76012000, 76042900 or 7604291010? Thank you According to our engineers might be unwrought Aluminum Alloy, but from the cylindrical shape should be cylindrical solid Aluminum Alloy, the two different export tariffs, were 0 and 15, we export alloy ingots are written Aluminum Alloy unwrought aluminum bar, whether can also write this? In fact, these two processes are the same. Thank you for your advice, thank you! Urgently!!!

- 76012000, the export tariff should be 30%, you say 76042900 (actually 76052900) refers to the aluminum alloy wire, 7604291010 tariff is 20%.Only at 76012000 and 7604291010, which should be forged;Personally think it should be the first 76012000

Send your message to us

Oneup Aluminum Bars - AA1070 C.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches