Grade ASTM A36 Round Steel Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High Quality A36 Round Steel Bar Large Quantity in Stock

Specifications of High Quality A36 Round Steel Bar Large Quantity in Stock

1.Competitive price

2.Prime quality

3.Best service

4.Quick deliver time

5 BV ,SGS third party inspection

Description of High Quality A36 Round Steel Bar Large Quantity in Stock

Description | Carbon Steel Rod/Carbon Steel Bar,carbon steel rod,carbon steel shaft,mild steel bar, mild steel shaft,ms bar | |

| Material | ASTM | 1005,1006,1008,1010,1015,1020,1025,1030,1035,1040,1045,1050,1055,1060,1065,1070,1080,1084,1016,1022 |

| DIN | Ck10,Ck15,Ck22,Ck25,Ck30,Ck35, Ck40,Ck45,Ck50, 30Mn4,40Mn4 | |

| BS | 040A04,095M15,045M10,080A40,045M10,080M50 | |

| Standard | GB/T799,ASTM A29,A108,A321,A575,BS970,DIN1652,JIS G4051 | |

| Section shape | Round,square,hexagonal,flat,angle | |

| Surface | Black painted,galvanized | |

| Specifications | Round bar | Diameter: 4mm~800mm |

| Angle bar | Size: 3mm*20mm*20mm~ 12mm*800mm*800mm | |

| Square bar | Size: 4mm*4mm~100mm*100mm | |

| Flat bar | Thickness: 2mm~100mm | |

| Width:10mm~500mm | ||

| Hexagonal | Size: 4mm~800mm | |

| Length | 2m,4m,5.8m,6m,11.8m,12m or as required. | |

| Trade terms | Payment terms | T/T,L/C,Western Union |

| Price terms | FOB,CIF,CFR,EXW | |

| Package | Bundled,wooden box for export standard package. | |

| Delivery Date | Normally according to the order quantity | |

| Application | Carbon steel rod applies to chemical industry, shipping industry, manufacturing industry,construction,decorate Industry,electric power,pump shafts, sanitary wares,furniture handles,boiler,high temperature resistant,low temperature resistant, corrosion resistant. | |

Company Introduction of High Quality A36 Round Steel Bar Large Quantity in Stock

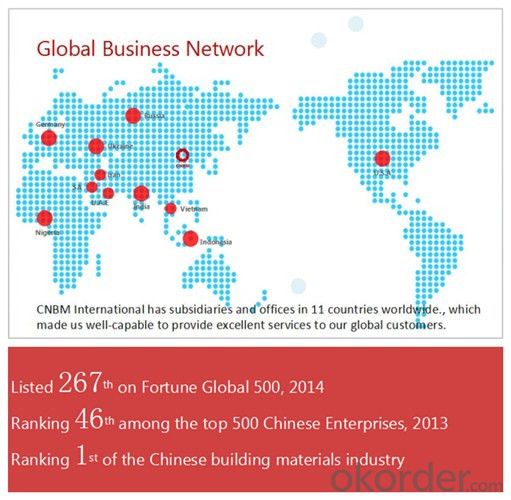

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of High Quality A36 Round Steel Bar Large Quantity in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How is special steel used in the production of bearings?

- Special steel is used in the production of bearings due to its unique properties such as high durability, corrosion resistance, and wear resistance. It helps in increasing the lifespan and performance of bearings, allowing them to withstand high loads and rotational speeds. Additionally, the special steel used in bearings undergoes precise heat treatment and surface finishing processes to ensure optimal performance and reduce friction, resulting in smoother operations in various industries such as automotive, aerospace, and manufacturing.

- Q: What are the different methods of preventing pitting corrosion in special steel?

- There are several methods to prevent pitting corrosion in special steel. One common approach is the use of corrosion-resistant alloys, such as stainless steel, which contain elements like chromium and nickel that form a protective oxide layer on the surface. Additionally, applying coatings or paints can provide a barrier against corrosive agents. Another effective method is cathodic protection, where a sacrificial anode or impressed current system is employed to protect the steel from corrosion. Regular inspection and maintenance, as well as controlling the environment by reducing exposure to corrosive substances, also play crucial roles in preventing pitting corrosion in special steel.

- Q: What are the properties of case-hardening steel?

- Case-hardening steel is a type of steel that possesses specific properties, such as high surface hardness and improved wear resistance. It achieves these properties through a process called case hardening, which involves heating the steel to a specific temperature and then introducing a carbon-rich environment. This process allows the steel to absorb carbon atoms, resulting in a hardened outer layer while maintaining a tough and ductile core. The hardened surface layer provides excellent resistance to abrasion and impact, making case-hardening steel suitable for applications requiring durability and strength, such as gears, shafts, and bearings.

- Q: What are the different methods for improving the magnetic properties of special steel?

- There are several methods that can be employed to improve the magnetic properties of special steel. 1. Heat Treatment: One common method is heat treatment, which involves subjecting the steel to specific heating and cooling processes. This can help to alter the atomic structure of the steel and enhance its magnetic properties. For example, annealing the steel at high temperatures followed by slow cooling can lead to the formation of a fine-grained microstructure, resulting in improved magnetic properties. 2. Alloying: Another approach is to add certain alloying elements to the steel. For instance, the addition of small amounts of elements like nickel, cobalt, or aluminum can significantly enhance the magnetic characteristics of the steel. These alloying elements can help to increase the saturation magnetization and improve the coercivity of the material. 3. Cold Working: Cold working, also known as cold deformation, involves subjecting the steel to mechanical stress at low temperatures. This process can cause the formation of dislocations and defects within the crystal structure of the steel, which can improve its magnetic properties. Cold working can lead to increased magnetization, improved permeability, and reduced hysteresis losses. 4. Grain Orientation: Another method is to align the grains of the steel in a specific direction. This can be achieved through processes like hot rolling or magnetic annealing. By aligning the grains, the steel can exhibit anisotropic magnetic properties, meaning it will have different magnetic characteristics depending on the direction of the applied magnetic field. 5. Surface Treatments: Surface treatments can also be employed to enhance the magnetic properties of special steel. Coatings like electroplating, electroless plating, or chemical vapor deposition can be used to modify the surface of the steel, leading to improved magnetic performance. These treatments can help to reduce eddy current losses, enhance corrosion resistance, and increase the magnetic permeability of the material. It is important to note that the choice of method for improving the magnetic properties of special steel depends on the specific requirements and desired characteristics. Each method has its advantages and limitations, and the selection should be made based on factors such as cost, feasibility, and the desired magnetic performance.

- Q: How does special steel perform in magnetic applications?

- Special steel performs well in magnetic applications due to its high magnetic permeability and low electrical conductivity. This allows it to efficiently conduct and concentrate magnetic fields, making it ideal for various magnetic devices and applications such as transformers, motors, generators, and magnetic sensors. Additionally, special steel can exhibit excellent magnetic properties such as high saturation magnetization and low coercivity, making it capable of generating strong magnetic fields and maintaining magnetization even in challenging conditions.

- Q: Can special steel be used in the production of artistic sculptures?

- Certainly, artistic sculptures can indeed be produced using special steel. Special steel, which pertains to steel alloys specifically designed and manufactured for specific applications, presents a plethora of benefits that render it suitable for the creation of sculptures. Primarily, special steel alloys boast exceptional strength and durability, enabling sculptors to fashion large and intricate structures that can withstand external forces and environmental conditions. This robustness and resilience prove crucial, especially for sculptures placed outdoors and exposed to weather elements such as rain, wind, and extreme temperatures. Moreover, special steel alloys offer pliability and malleability, allowing for easy shaping and forming. Artists can effortlessly mold and manipulate the steel into various shapes and sizes, bringing their creative visions to life. By employing techniques like welding, cutting, and bending, sculptors can shape the steel into their desired forms, resulting in one-of-a-kind and captivating sculptures. Furthermore, special steel alloys can be finished in diverse ways, such as polishing, painting, or coating, to enhance their aesthetic appeal. This grants artists the ability to incorporate different textures, colors, and surface finishes into their sculptures, further augmenting their artistic value. Additionally, special steel alloys provide resistance to corrosion, which is especially significant for sculptures situated in outdoor or humid environments. This corrosion resistance ensures that the sculptures retain their visual allure and structural integrity over time, reducing the need for frequent maintenance and repairs. In conclusion, special steel presents a wide array of advantages that make it an exceptional choice for the production of artistic sculptures. Its strength, pliability, aesthetic appeal, and resistance to corrosion equip artists with the necessary tools to create visually striking and enduring sculptures that can be cherished for years to come.

- Q: What are the different corrosion testing methods used for special steel?

- There are several corrosion testing methods used for special steel, including salt spray testing, electrochemical testing, immersion testing, and accelerated corrosion testing. These methods help to assess the corrosion resistance and durability of special steel in different environments and conditions.

- Q: What are the different methods of surface cleaning for special steel?

- There are several different methods of surface cleaning for special steel, each with its own advantages and applications. Some of the most common methods include: 1. Mechanical Cleaning: This method involves the use of mechanical tools like wire brushes, sandpaper, or abrasive pads to physically remove dirt, rust, or other contaminants from the surface of the steel. Mechanical cleaning is effective for light to moderate surface contamination and is often used as a pre-treatment before other cleaning methods. 2. Chemical Cleaning: Chemical cleaning involves the use of specific chemicals or cleaning agents to dissolve or loosen contaminants on the surface of the special steel. These chemicals can be applied through brushing, spraying, or immersion methods. Acid-based cleaners are commonly used for removing scale, rust, or oxide deposits, while alkaline cleaners are effective for removing oils, greases, or organic residues. 3. Electrochemical Cleaning: This method utilizes electrochemical reactions to remove surface contaminants from special steel. Electrochemical cleaning involves the use of an electric current and an electrolyte solution to dissolve or dislodge dirt, rust, or other deposits. This method is particularly useful for cleaning intricate or hard-to-reach areas on the steel surface. 4. Ultrasonic Cleaning: Ultrasonic cleaning involves the use of high-frequency sound waves in a liquid medium to agitate and remove contaminants from the surface of special steel. This method is highly effective for removing fine particles, oils, greases, or other organic residues from complex or delicate surfaces. 5. High-pressure Water Jetting: High-pressure water jetting uses a focused stream of pressurized water to remove contaminants from the special steel surface. This method is particularly useful for removing heavy deposits, coatings, or paints from large areas. It can be adjusted to different pressure levels to accommodate various degrees of surface contamination. It is important to note that the choice of surface cleaning method for special steel will depend on factors such as the type and extent of contamination, the condition of the steel surface, the desired level of cleanliness, and the specific requirements of the application. It is recommended to consult with experts or professionals in the field to determine the most suitable method for a given situation.

- Q: What are the different methods of surface powder coating for special steel?

- Special steel can be coated using various surface powder coating methods. These methods include: 1. Electrostatic powder coating: By charging the powder particles and spraying them onto the steel surface, a uniform and durable coating is achieved. The charged particles are attracted to the grounded steel. 2. Fluidized bed powder coating: Preheating the steel and dipping it into a fluidized bed of powder particles results in a smooth coating. The heat causes the powder to melt and adhere to the steel surface. Excess powder is removed through shaking or blowing air. 3. Flame spray powder coating: This method involves heating the powder particles with a flame and then spraying them onto the steel surface. The melted powder solidifies to form a coating. This method is commonly used for repairing damaged coatings or larger steel structures. 4. Thermal spray powder coating: By heating and propelling the powder particles onto the steel surface using a thermal spray gun, a dense and well-adhered coating is achieved. This method is suitable for high-wear applications and corrosive environments. 5. UV-cured powder coating: Applying a UV-sensitive powder onto the steel surface and exposing it to UV light initiates a chemical reaction that results in a hard coating. UV-cured powder coating is known for its fast curing time and excellent resistance to chemicals and UV radiation. Each method has its own advantages and considerations, and the choice depends on factors such as the specific requirements of the steel surface, desired coating thickness, and production volume.

- Q: What are the specific requirements for special steel used in the railway track industry?

- The specific requirements for special steel used in the railway track industry include high strength, durability, and resistance to wear, fatigue, and corrosion. It must also possess good weldability and maintain its mechanical properties under varying temperatures and loading conditions. Additionally, the steel should comply with specific industry standards and undergo rigorous testing and quality control measures to ensure its reliability and safety for railway track applications.

Send your message to us

Grade ASTM A36 Round Steel Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords