AA1XXX Mill-Finished C.C Aluminum Bars for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction Description

AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction Description is cut from aluminum coils 1xxx. The aluminum content of aluminum sheets 1xxx C.C quality is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

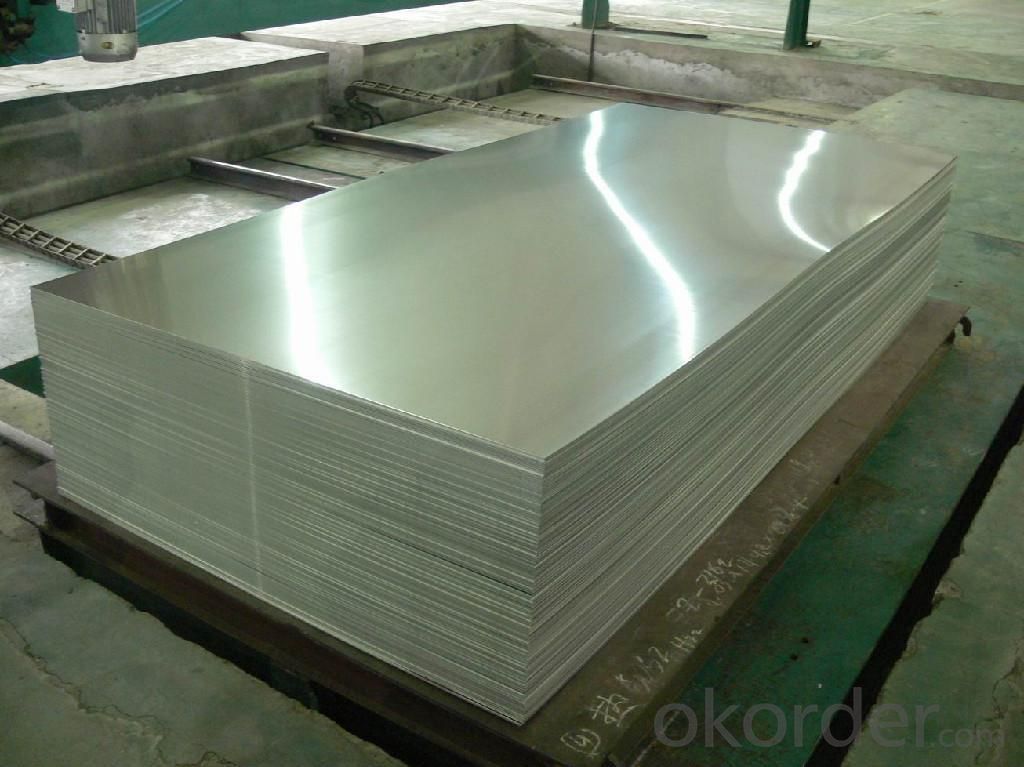

3.AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction Images

4.AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction Specification

Alloy | AA1xxx |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction.

B.When will you deliver the products?

AA1xxx Mill-Finished C.C Aluminum Sheets Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: How much should the speed of the 20mm aluminum bar and the wire speed be cut off by the 2mm mechanical cutting machine of the NC machine?

- Speed is about 500r, line speed 5m/s on the line, feed speed election 0.1mm/r, I hope useful for you, ha ha!

- Q: Can aluminum bars be used as car wheels?

- Aluminum bar also depends on his composition is not A356, and now in addition to forging ingredients are different, basically A356

- Q: Numerical control car diameter 10, length 70 aluminum bars, how to solve the earthquake mark?

- Withstand the processing of the top, there will be no vibration lines.

- Q: What's the latest price for 6063 Aluminium bars?

- Generally speaking,The price of aluminum ingot base (= current month average price, to the date and four working days, average delivery day and 4 days, five days before the shipment, and other contractual pricing) + price + + processing fees increase state of special size increases with price + other.At present we Zhongfu special aluminum 6063 aluminum rod hot, very high price, welcome to consult oh!

- Q: Aluminum stick, 6351-t6? What do you mean?

- T6 refers to heat treatment process. The state of artificial ageing after T6 solution heat treatment is applicable to the products which are no longer subjected to cold working after the solid solution heat treatment (can be straightened and leveling, but does not affect the mechanical performance limit).

- Q: Excuse me, what's the temperature and speed of the 6063 aluminum bar casting?

- Now die-casting aluminum process according to material size, with electric furnace heating to 600-700 degrees. Small material high temperature heating, aniseed low, or too soft, not easy to move.It doesn't make sense to ask such questionsOr find their own information it!

- Q: How do the scrap aluminum rod

- Coarse removal of impurities - melting removes molten impurities (lower than aluminium melting point) - removal of impurities (aluminum melting, removal of aluminum at higher melting points) - casting aluminum rods (or after cooling extrusion)

- Q: I do lathe processing, how to make 6061 of the aluminum bars crisp, or what good processing methods?

- The groove must be smooth. In addition jiaqie chip liquid is the key, of course, is the best add oil.

- Q: The temperature of the one meter aluminum bar rises by 1 degrees and how many degrees

- Once the need to absorb 4200 Joule heat per liter of water increased, the 1 card is about 4.2 joules, so it needs 1000 cards; the specific heat capacity of water is 4.2 x 10 fand J/ (kg C) calculation formula of Q=cm delta T Q said C M said the specific heat capacity of heat temperature change Q delta T quality of absorption of =cm (t-t0) Q t said at the end of the heat absorption temperature and initial temperature of Q =cm t0 (t0-t.

- Q: 42 diameter aluminum bars, CNC lathes, what cutting head, how much speed?

- Alloy aluminum 1300, YT15, YT30, YW2 will do.

Send your message to us

AA1XXX Mill-Finished C.C Aluminum Bars for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches