Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Round Bar in stock

Descriptio of Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

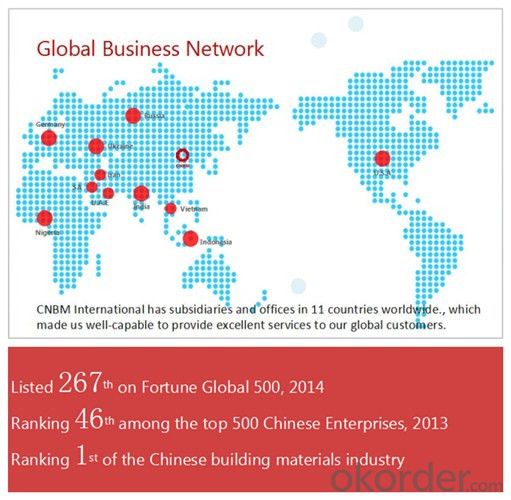

Company Information of Steel Round Bar in Stock

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different types of tool and die steel?

- There are several different types of tool and die steel, including high-speed steel (HSS), carbon tool steel, alloy tool steel, and powdered metal steel. Each type has specific properties and characteristics that make it suitable for different applications in tool and die making.

- Q: How are nickel-based alloys used in the aerospace industry?

- Nickel-based alloys are extensively used in the aerospace industry due to their exceptional strength, heat resistance, and corrosion resistance properties. These alloys are commonly used in the manufacturing of various aerospace components such as turbine blades, combustion chambers, and exhaust systems. Their high temperature stability allows them to withstand extreme conditions in jet engines, while their corrosion resistance ensures longevity and reliability. Additionally, nickel-based alloys also contribute to weight reduction in aircraft, as they possess a high strength-to-weight ratio, making them an ideal choice for enhancing fuel efficiency and overall performance in the aerospace industry.

- Q: What are the different methods of surface etching for special steel?

- There are several different methods of surface etching that can be used for special steel. These methods include: 1. Chemical etching: Chemical etching involves the use of various acids or other chemical solutions to selectively remove material from the surface of the steel. This method allows for precise control over the etching process and can create highly detailed patterns or designs on the steel surface. 2. Electrochemical etching: Electrochemical etching uses an electrical current to etch the surface of the steel. This method can be particularly effective for creating deep, uniform etches and is often used for marking or labeling purposes. 3. Laser etching: Laser etching involves the use of a high-powered laser to remove material from the steel surface. This method is highly precise and can create very intricate designs or markings. Laser etching is commonly used for branding or decorative purposes. 4. Mechanical etching: Mechanical etching utilizes physical abrasion to remove material from the steel surface. This can be done manually using tools such as sandpaper or brushes, or with the help of machinery like a sandblaster. Mechanical etching is often used to create a textured or roughened surface. 5. Plasma etching: Plasma etching involves the use of a high-energy plasma to remove material from the steel surface. This method is particularly useful for creating very fine, shallow etches and is commonly used in microfabrication or semiconductor manufacturing. Each of these methods has its own advantages and limitations, and the choice of which method to use will depend on factors such as the desired outcome, the type of special steel being etched, and the available equipment and resources.

- Q: How does special steel perform in high-pressure hydrogen environments?

- Special steel performs well in high-pressure hydrogen environments due to its high strength, corrosion resistance, and ability to withstand hydrogen embrittlement. It is specifically designed to resist the damaging effects of hydrogen, making it a reliable choice for applications in these environments.

- Q: What are the factors that affect the mechanical properties of special steel?

- The mechanical properties of special steel are affected by several factors. Some of the key factors include the chemical composition of the steel, the heat treatment process, the presence of impurities or alloying elements, the microstructure of the steel, and the manufacturing process used. These factors can greatly influence the steel's strength, hardness, toughness, ductility, and corrosion resistance.

- Q: What are the specific requirements for special steel used in the railway sector?

- Ensuring the safety, durability, and efficient operation of railway infrastructure in the railway sector relies heavily on meeting the specific requirements for special steel. Some of the key requirements include: 1. Exceptional strength is essential for the special steel used in the railway sector to withstand heavy loads, vibrations, and impacts. This is crucial to maintain the structural integrity of tracks, bridges, and other components. 2. To minimize the need for frequent maintenance and replacement, special steel must have excellent wear resistance as railway tracks and wheels experience significant wear due to continuous contact and friction. 3. Railway components are subjected to constant cyclic loading, which demands high fatigue resistance in the steel. This ensures they can withstand repetitive stress and prevents fatigue failures. 4. Special steel must possess good corrosion resistance to prevent rusting and degradation, thereby ensuring a longer service life in the face of various environmental conditions such as moisture, extreme temperatures, and chemicals. 5. In certain applications like rail joints and fasteners, special steel is exposed to high temperatures due to friction and stresses. Good heat resistance is necessary for the steel to maintain its mechanical properties under such conditions. 6. Good weldability of special steel is essential to enable efficient and reliable joining of components during manufacturing and maintenance processes in the railway sector. 7. The steel must exhibit sufficient ductility and toughness to absorb energy and resist fracture in the event of a collision or impact, ensuring passenger safety. 8. Special steel used in the railway sector must maintain its dimensional stability under varying temperatures and loads to prevent deformation and ensure proper alignment of tracks and components. Meeting these specific requirements for special steel in the railway sector is crucial to ensure the safety, reliability, and longevity of railway infrastructure. This contributes to the smooth operation of the entire transport network.

- Q: How is the toughness of special steel measured?

- The toughness of special steel can be assessed by specific tests and methodologies that evaluate its capacity to absorb energy and withstand fractures. One widely used approach is the Charpy V-Notch (CVN) test, in which a notched specimen is struck by a pendulum hammer, and the energy absorbed during fracture is measured. The results are then expressed as the energy absorbed per unit area, typically in joules per square centimeter (J/cm²) or foot-pounds per square inch (ft-lb/in²). Another commonly employed test is the Izod test, which is similar to the CVN test but involves a different specimen geometry. Furthermore, engineers and manufacturers may also employ other mechanical tests such as tensile strength, impact strength, and fracture toughness measurements to evaluate the toughness of special steel. These tests are invaluable in determining the suitability of special steel for various applications, particularly those requiring exceptional resistance to impact or sudden loading.

- Q: What are the advantages of using special steel over other materials?

- There are several advantages of using special steel over other materials. Firstly, special steel offers superior strength and durability, making it ideal for applications that require high load-bearing capacity or resistance to wear and tear. Secondly, special steel has excellent corrosion resistance properties, which is particularly important for industries such as construction, automotive, and marine. Additionally, special steel can be easily customized and shaped to meet specific design requirements, providing flexibility in manufacturing processes. Lastly, special steel often exhibits high heat resistance and excellent mechanical properties, making it suitable for demanding environments and critical applications.

- Q: What are the different methods of strengthening special steel?

- There are several methods of strengthening special steel, each with its own advantages and applications. One common method is through heat treatment, which involves heating the steel to a specific temperature and then cooling it rapidly or slowly, depending on the desired outcome. This can include processes like quenching, tempering, and annealing, which modify the microstructure of the steel to enhance its mechanical properties. Another method is alloying, where different elements are added to the steel to improve its strength. For example, adding elements like chromium, nickel, or molybdenum can increase the steel's resistance to corrosion, while elements like vanadium or tungsten can enhance its hardness and wear resistance. Cold working is another technique used to strengthen special steel, which involves deforming the steel at room temperature through processes like rolling, forging, or drawing. This helps to align the steel's crystalline structure, increasing its strength and hardness. Additionally, surface treatments can be applied to special steel to improve its strength. These can include techniques like carburizing, nitriding, or plating, which introduce a hardened layer or coating on the surface of the steel to enhance its wear resistance and durability. Each of these methods has its own advantages and can be tailored to suit specific applications and requirements. By combining various strengthening techniques, special steel can be customized to meet a wide range of industrial needs, making it a versatile and reliable material.

- Q: What are the different methods of improving the strength of special steel?

- There are several methods to enhance the strength of special steel, including alloying, heat treatment, and cold working. Alloying involves adding specific elements to the steel composition to enhance its properties, such as chromium for improved corrosion resistance or molybdenum for increased strength. Heat treatment techniques like quenching and tempering can alter the steel's microstructure, making it stronger and more durable. Cold working, which includes processes like rolling or forging, can also increase the strength of special steel by deforming its crystal structure and inducing strain hardening.

Send your message to us

Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords