Customized Extruded Aluminum Profiles for Industrial Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Industrial Aluminium Profiles For Machinery Description

Industrial Aluminium Profiles For Machinery is one semi-finished aluminium material. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel. Each profile is wrapped by the particular paper to avoid the scratching between each profile and also prevent the moisture in the air. Outside the bundle is fixed with the four wooden boards including support board vertically and base board on horizontal level. There are steel belts outside the boards to strap and tighten.

2. Specification of Industrial Aluminium Profiles For Machinery

Industrial Aluminium Profiles For Machinery | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Industrial Aluminium Profiles For Machinery

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Industrial Aluminium Profiles For Machinery

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Industrial Aluminium Profiles For Machinery

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

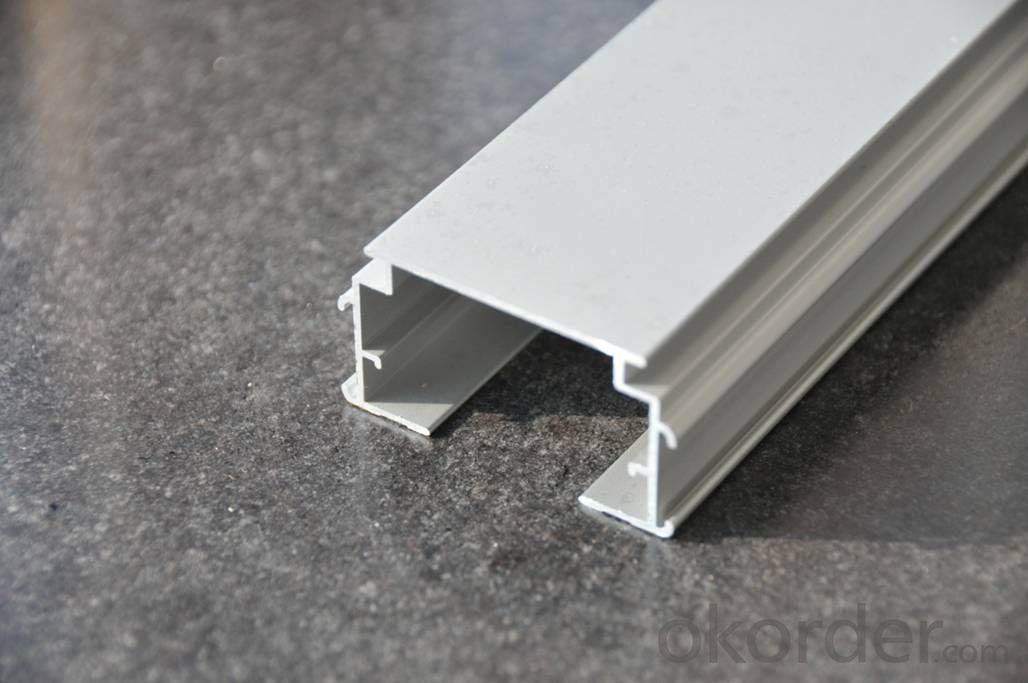

6. Image of Industrial Aluminium Profiles For Machinery

7. Package and shipping of Industrial Aluminium Profiles For Machinery

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the aluminum section table?

- Aluminum frame is used to do the frame, console ah. Jing Teng aluminum professional undertake assembly line workbench ~!

- Q: Can aluminum profiles be used for DIY projects or home improvement?

- Yes, aluminum profiles can be used for DIY projects or home improvement. Aluminum profiles are versatile and can be easily customized and fabricated to fit various applications. They are lightweight, durable, and resistant to corrosion, making them suitable for a wide range of projects such as shelving, framing, furniture, and even outdoor structures like pergolas or fences. Additionally, aluminum profiles are available in different shapes and sizes, allowing for flexible and creative designs.

- Q: What are the reasons for the slow down of aluminum extrusion press?

- Try to adjust it properlyCheck for premature transferCheck whether the reaction speed of the filling valve is fast enoughThink of the above five points temporarily. Hope to be of some help to you.

- Q: This question asks for an explanation of the various methods employed in the manufacturing of aluminum profiles.

- <p>Aluminum profiles are produced using several manufacturing processes, each suited to different applications and profile shapes. The primary methods include: Casting, where molten aluminum is poured into molds to form profiles; Extrusion, the most common process, where aluminum is pushed through a die to create long, continuous shapes; Rolling, used for creating flat or curved sheets and plates; Forging, which involves shaping aluminum by applying compressive forces; and Machining, where aluminum profiles are cut and shaped using tools. Each process has its advantages and is chosen based on the desired profile's complexity, strength, and cost-effectiveness.</p>

- Q: What are the different anodizing colors available for aluminum profiles?

- There are several different anodizing colors available for aluminum profiles, including clear, black, bronze, gold, and champagne.

- Q: Are aluminum profiles suitable for use in sustainable or eco-friendly construction projects?

- <p>Yes, aluminum profiles can be used for green building projects. They are valued for their recyclability, which contributes to sustainability. Aluminum is lightweight, strong, and requires less energy to produce and transport compared to other materials like steel. Additionally, aluminum's durability can lead to a longer lifespan, reducing the need for frequent replacements and thus minimizing waste. Moreover, aluminum can be used in energy-efficient designs, such as in window frames that provide better insulation, further enhancing the green credentials of a building.</p>

- Q: What is aluminum profile?

- Aluminum is the aluminum bar through hot melt, extrusion, so as to obtain different cross-section of aluminum. The production process of aluminum profile mainly includes three processes: casting, extrusion and coloring. Among them, the color mainly includes: oxidation, electrophoresis coating, fluorine carbon spraying, powder spraying, grain transfer and other processes.

- Q: What are the different grades of aluminum used in profiles?

- The different grades of aluminum commonly used in profiles include 6061, 6063, and 6082. These grades vary in terms of their mechanical properties, corrosion resistance, and suitability for different applications.

- Q: This question seeks to understand the various types of aluminum profiles that are specifically used in the construction of building facades.

- <p>Aluminum profiles for facades come in various types, each serving different purposes and functions. Common types include: 1. <strong>Vertical and Horizontal Mullions</strong>: These are the primary structural elements that form the framework of the facade. 2. <strong>Transoms and Muntins</strong>: Used to divide the glass into panels, providing both aesthetic appeal and structural integrity. 3. <strong>Capping Profiles</strong>: These cover the ends of the mullions, providing a finished look and protecting the edges. 4. <strong>Cover Caps</strong>: Used to conceal the fasteners and provide a clean, streamlined appearance. 5. <strong>Angle Connectors</strong>: Facilitate the connection of different profile sections at various angles. 6. <strong>Gaskets and Seals</strong>: Ensure weatherproofing and insulation. 7. <strong>Accessories</strong>: Such as handles, locks, and hinges, which are integrated into the facade system. Each type is designed to meet specific performance requirements, such as load-bearing capacity, resistance to environmental factors, and aesthetic considerations.</p>

- Q: This question asks for methods to prevent rusting on aluminum profiles during the installation process.

- <p>To prevent rusting on aluminum profiles during installation, follow these steps: Ensure the aluminum profiles are clean and free from any contaminants before installation. Use stainless steel screws and fittings to avoid galvanic corrosion. Keep the profiles dry and avoid contact with moisture. Apply a protective coating or sealant if the profiles will be exposed to harsh environments. Store aluminum profiles in a dry place to prevent moisture absorption. Regularly inspect and maintain the profiles to catch any signs of corrosion early.</p>

Send your message to us

Customized Extruded Aluminum Profiles for Industrial Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords