Extruded Aluminum Stock

Extruded Aluminum Stock Related Searches

Extruded Aluminum Bar Stock Extruded Aluminum Frame Stock Aluminum Extrusion Stock Aluminum Extrusions Stock Extruded Aluminum Fence Stock Aluminum Extrusion Shapes Stock Extruded Aluminum Stock Shapes Aluminum Stock Anodized Aluminum Stock Stock Aluminum Aluminum Frame Stock Aluminum Engraving Stock Solid Aluminum Stock 1x2 Aluminum Stock Aluminum Machining Stock Aluminum Manufacturers Stock Brushed Aluminum Stock Aluminum Price Stock Us Aluminum Stock Aluminum Box Stock China Aluminum Stock Anodized Aluminum Sheet Stock Aluminum Lathe Stock Aluminum Tubing Stock Aluminum Gun Stock Aluminum Metal Stock Aluminum Extrusions Stock Shapes Tubular Aluminum Stock Cnc Aluminum Stock Aluminum Rectangle StockExtruded Aluminum Stock Supplier & Manufacturer from China

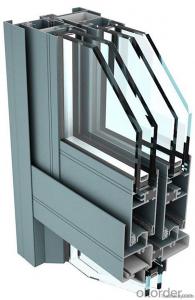

Extruded Aluminum Stock refers to a range of aluminum profiles that have been manufactured through the process of extrusion. This method involves forcing aluminum alloy billets through a die to create a desired shape and size. The resulting products are known for their high strength, lightweight, and excellent corrosion resistance, making them ideal for a variety of applications.These extruded aluminum profiles are widely used across numerous industries, including construction, automotive, aerospace, and electronics. They can be found in applications such as window frames, door frames, support structures, and various mechanical components. Due to their versatility and durability, extruded aluminum stocks have become a popular choice for both commercial and industrial purposes.

Okorder.com is a leading wholesale supplier of extruded aluminum stock, boasting a large inventory of high-quality products. They offer a comprehensive range of aluminum profiles to cater to the diverse needs of their customers. By partnering with Okorder.com, businesses can access a reliable source for extruded aluminum stock, ensuring that they receive the best materials for their specific applications.