Extruded Aluminum Profiles for Air Handling Unit Case with Thermal Break

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

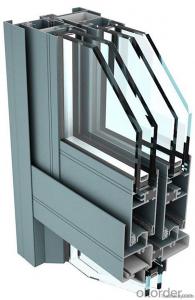

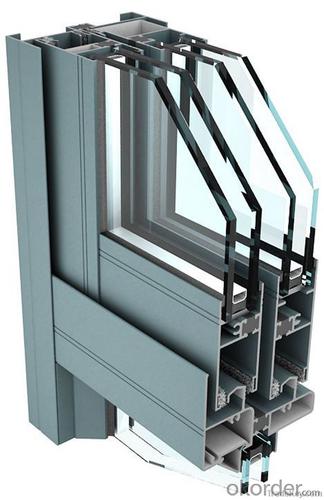

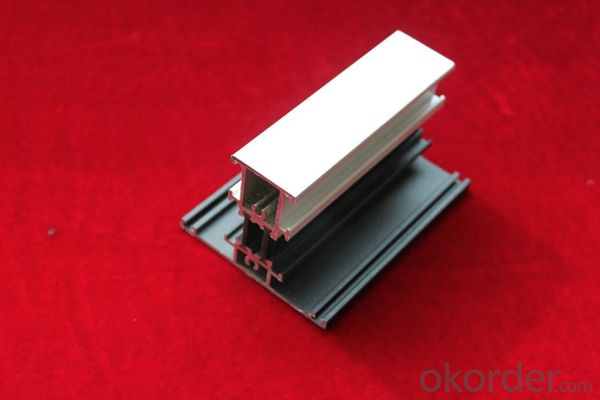

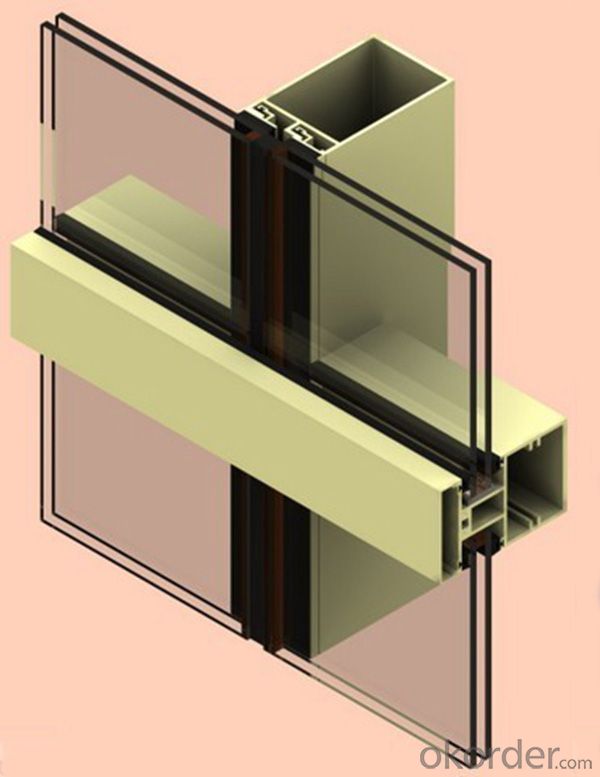

5. Image of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

6. Package and shipping of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: Are aluminum profiles suitable for use in exterior wall insulation systems for residential buildings?

- <p>Yes, aluminum profiles can be used for exterior wall insulation systems in residential buildings. They are known for their durability, corrosion resistance, and low thermal conductivity, which makes them ideal for creating thermal barriers. Aluminum profiles can support the structure of the insulation system, providing a stable framework while also contributing to energy efficiency by reducing heat transfer. However, it's important to ensure that the profiles are properly sealed and insulated to prevent thermal bridging and to maintain the overall insulation performance of the building envelope.</p>

- Q: What are the different surface texturing options for aluminum profiles?

- Some of the different surface texturing options for aluminum profiles include anodizing, powder coating, brushing, polishing, and sandblasting. These techniques can be used to create different textures and finishes on the surface of the aluminum profiles, enhancing their appearance and providing additional protection against corrosion and wear.

- Q: What are the differences between horizontal and vertical aluminum profiles?

- Horizontal vertical hanger in the middle on the head,Therefore, the horizontal number will affect the surface a little, and when you have to find non decorative surface hangingThe vertical head is better, a hanging point, just cut off

- Q: This question asks whether aluminum profiles can be joined using welding or bolting methods.

- <p>Yes, aluminum profiles can be both welded and bolted together. Welding aluminum requires specific techniques and equipment due to its high thermal conductivity, but it is possible and results in a strong joint. Bolting is a common method for joining aluminum profiles, as it is quick, easy, and does not require melting the material. It is important to use appropriate hardware and techniques to ensure a secure and durable connection.</p>

- Q: This question asks about the various standards and specifications that govern the manufacturing and quality of aluminum profiles.

- <p>Aluminum profiles are governed by a variety of standards and specifications that ensure quality and consistency. These include international standards such as ISO 7599, which specifies tolerances for aluminum profiles, and ASTM B221, which covers aluminum and aluminum-alloy extruded bars, rods, and profiles. National standards like the European EN 573 or the Chinese GB/T 6892 also provide guidelines for aluminum profiles. Specifications cover dimensions, mechanical properties, surface finishes, and tolerances. Each standard may have specific requirements for different types of profiles, such as those used in construction, automotive, or aerospace industries. Compliance with these standards is crucial for ensuring the safety, performance, and reliability of aluminum profiles in various applications.</p>

- Q: How to process the wood grain transfer of aluminum profile? Thank you

- Popular talk is to transfer grain, electrostatic powder coating on metal material, vacuum equipment through the wood grain transfer on the coating material in high temperature, pay pressure, ink sublimation transfer printing or transfer film on the penetration into a conversion process in the coating. Now there are very good equipment in China ~!

- Q: Are aluminum profiles suitable for automotive racks and carriers?

- Aluminum profiles, indeed, possess the appropriateness for automotive racks and carriers. Being both lightweight and robust, aluminum emerges as an optimal material for instances that prioritize weight reduction, such as automotive racks and carriers. The adaptability and flexibility of aluminum profiles enable their design and engineering to cater to specific requirements, facilitating customization. Besides, aluminum's resistance to corrosion guarantees the endurance and long-lasting nature of automotive racks and carriers, even in unfavorable weather conditions. Moreover, the notable strength-to-weight ratio of this material contributes to an enhanced fuel efficiency and reduced emissions. In summary, aluminum profiles furnish a dependable and efficient resolution for automotive racks and carriers.

- Q: Are aluminum profiles energy-efficient?

- Yes, aluminum profiles are considered to be energy-efficient. Aluminum is a highly conductive material, which means it can effectively transfer heat or cold. This property allows aluminum profiles to provide excellent thermal insulation, helping to minimize energy loss and maintain a consistent indoor temperature. Additionally, aluminum profiles can be designed with thermal breaks, which further enhance their energy efficiency by reducing heat transfer between the inside and outside of a building. These features make aluminum profiles a popular choice for windows, doors, and other building components, as they contribute to energy savings and reduce the overall carbon footprint of a structure.

- Q: Can aluminum profiles be used for medical equipment or devices?

- Yes, aluminum profiles can be used for medical equipment or devices. Aluminum is a widely used material in the medical industry due to its unique properties. It is lightweight, yet strong and durable, making it suitable for various medical applications. Aluminum profiles can be used to manufacture medical equipment such as hospital beds, wheelchairs, surgical tables, and diagnostic equipment. The corrosion resistance of aluminum also makes it ideal for medical devices that come in contact with bodily fluids or chemicals. Additionally, aluminum is easily sterilizable, which is crucial for maintaining a hygienic environment in healthcare settings. Overall, aluminum profiles offer numerous advantages for medical equipment and devices, making them a popular choice in the medical industry.

- Q: This question asks for methods to prevent rusting on aluminum profiles during the installation process.

- <p>To prevent rusting on aluminum profiles during installation, follow these steps: Ensure the aluminum profiles are clean and free from any contaminants before installation. Use stainless steel screws and fittings to avoid galvanic corrosion. Keep the profiles dry and avoid contact with moisture. Apply a protective coating or sealant if the profiles will be exposed to harsh environments. Store aluminum profiles in a dry place to prevent moisture absorption. Regularly inspect and maintain the profiles to catch any signs of corrosion early.</p>

Send your message to us

Extruded Aluminum Profiles for Air Handling Unit Case with Thermal Break

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords