One Up Aluminum Bars - AA1100 C.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1100 C.C Mill Finished Aluminum Circles used for Cookware Description

AA1100 C.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1100 C.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1100 C.C Mill Finished Aluminum Circles used for Cookware

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

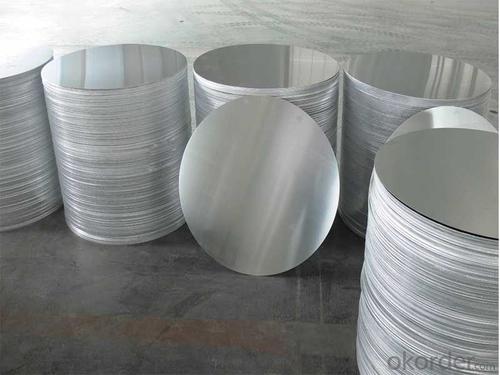

3.AA1100 C.C Mill Finished Aluminum Circles used for Cookware Images

4.AA1100 C.C Mill Finished Aluminum Circles used for Cookware Specification

Alloy | AA1100 |

Temper | H14, H16, H18,O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1100 C.C Mill Finished Aluminum Circles used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

How to guarantee the quality?

---Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1100 C.C Mill Finished Aluminum Circles used for Cookware.

- Q: What are the requirements of industrial profiles for aluminum bars?

- Industrial profiles are divided into assembly lines and profiled bars! The domestic assembly line profiles are mainly made of 6063 material!

- Q: Which corrosion resistant aluminum bars 2A12 and LF21?

- Mainly used in the manufacture of a variety of high load parts and components (but excluding stamping parts, forgings), such as aircraft skeleton parts, skin, bulkhead, wing ribs, wing beams, rivets and other parts below 150 degrees celsius.LF21 AL-Mn system is a kind of antirust aluminum alloy, the most widely used, the strength of the alloy is not high (slightly higher than that of pure aluminum), can be strengthened by heat treatment, so the use of cold processing methods to improve its mechanical properties in annealing state have high plasticity, in the semi cold hardening plastic is good, when the low plasticity of cold hardening, good corrosion resistance, good weldability, poor machinability. tc.

- Q: What are the differences between aluminum bars 5052 and 6063?

- 5052 aluminum alloy density: 2.68g/cm3; 6063 aluminum alloy density: 2.71g/cm3. aluminum alloy casting and extrusion form density is different, extrusion aluminum alloy density is higher.

- Q: What is an aluminum rod intermediate frequency heating furnace?

- The utility model relates to an aluminum rod heating furnace for extrusion, which is suitable for heating larger diameter aluminum bars, has fast heating speed and relatively accurate temperature control.

- Q: Now processing D8 long 300 aluminum rod, with instrument car processing, sleeve will pinch aluminum rod, is there any good way or suggestion? At present we do with bakelite collet, but life is not enough. Please master suggestions, thank you!

- Thank you for your reply, now we also generally know the direction, is the choice of soft material collet, remove the sharp edges,

- Q: Basic information of 6063 aluminum bar

- The role of 1.2 Si and the amount of Si that affect all Mg in the alloy can be in the form of Mg2Si phase, to ensure the full play of the role of Mg. With the increase of Si content, the grain of the alloy becomes thinner, the fluidity of the metal increases, the casting performance becomes better, the strengthening effect of heat treatment increases, the tensile strength of the section increases, while the plasticity decreases, and the corrosion resistance becomes worse.

- Q: For example, an aluminum bar is cut once and returned to the secondary cutting

- Why do you cycle three times? G96p100q300L3Then you have to go up and down the starting point three times

- Q: Aluminum Alloy extruded aluminum bar, not straight, with wavy continuous bending like uneven thickness like, our specification is 90110120, that is the same with this problem, do not know how, seek professional help

- Extruded products rarely have straight, which have a relationship with mold, quenching, traction and cooling system. After production, you can straighten it with the drawing machine.

- Q: Does the smell of burning aluminum bars often affect fertility?

- It will be! Although aluminum is not heavy metals, it belongs to non-ferrous metals! Too much absorption is harmful to the human body

- Q: Can the internal and external grinding mill grind the aluminum bar?

- The Hauck tool installed in the lathe up cylindrical grinder, instead of the traditional internal grinder, abrasive belt grinding machine and screw grinder, without two clamping, without grinding wheel, abrasive belt, clamping and processing can achieve a Ra0.2 mirror effect on lathe. Hauck can also be installed on the grinder, for high-precision, high hardness parts, easy processing to mirror effect.

Send your message to us

One Up Aluminum Bars - AA1100 C.C Mill Finished Aluminum Circles for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches