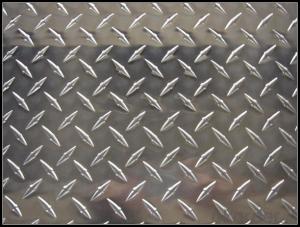

Bright Aluminum Diamond Plate

Bright Aluminum Diamond Plate Related Searches

Bright Aluminum Tread Plate Brazing Aluminum Diamond Plate White Aluminum Diamond Plate Aluminum Black Diamond Plate Polished Aluminum Diamond Plate Black Aluminum Diamond Plate Black Diamond Plate Aluminum Buy Aluminum Diamond Plate Bending Aluminum Diamond Plate Aluminum Diamond Plate Panels Anodized Aluminum Diamond Plate Aluminum Diamond Plate Strips Colored Aluminum Diamond Plate Aluminum Dimond Plate Aluminum Sheet Diamond Plate Sheet Aluminum Diamond Plate Diamond Plate Sheet Aluminum Aluminum Diamond Deck Plate Aluminum Diamond Plate Nearby Bending Diamond Plate Aluminum Wholesale Aluminum Diamond Plate Cosmetic Aluminum Diamond Plate Aluminum Diamond Plate Roll Welding Aluminum Diamond Plate Buffing Diamond Plate Aluminum Sheet Diamond Plate Aluminum Thin Aluminum Diamond Plate 1 2 Aluminum Diamond Plate Aluminum Diamond Plate For Sale Aluminum Diamond Plate BoxBright Aluminum Diamond Plate Supplier & Manufacturer from China

Bright Aluminum Diamond Plate is a type of aluminum sheet material that features a distinctive diamond-shaped pattern on its surface, providing both aesthetic appeal and enhanced traction. This product is widely recognized for its durability, corrosion resistance, and slip resistance, making it an ideal choice for various applications. The usage scenarios for Bright Aluminum Diamond Plate include industrial flooring, ramps, walkways, and platforms, where safety and slip resistance are of paramount importance. Additionally, it is utilized in the automotive, aerospace, and construction industries due to its lightweight and high-strength properties. Okorder.com is a leading wholesale supplier of Bright Aluminum Diamond Plate, offering a vast inventory of this product to cater to the diverse needs of customers across different industries. By maintaining a large stock, Okorder.com ensures prompt delivery and competitive pricing for Bright Aluminum Diamond Plate, making it a reliable choice for businesses seeking high-quality aluminum materials.Hot Products