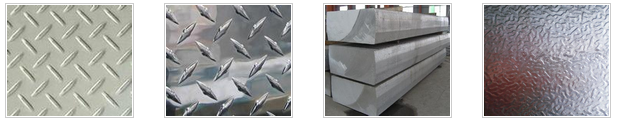

Aluminium Tear Plates, Bright Diamond

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Tear Plates, Bright Diamond :

Aluminium Tear Plates, Bright Diamond is widely used for decorative purposes in construction, packing and appliance. Aluminium Tear Plates, Bright Diamond is also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Main Features of Aluminium Tear Plates, Bright Diamond :

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminium Tear Plates, Bright Diamond

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm-1500mm

4. Production of Aluminium Tear Plates, Bright Diamond

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: This question asks for a comparison between aluminum sheets and other types of sheet metal regarding their strength and durability.

- <p>Aluminum sheets are known for their high strength-to-weight ratio, making them lighter than many other sheet metals such as steel. They offer excellent corrosion resistance, which contributes to their durability. However, in terms of sheer strength, aluminum is not as strong as steel or titanium. Steel is stronger but also heavier, and while titanium is very strong and durable, it is also more expensive and less commonly used in construction and manufacturing. Aluminum's malleability allows it to be easily shaped and formed, and it is also non-magnetic and has good thermal conductivity. Overall, aluminum is a popular choice for applications requiring a balance between strength, weight, and resistance to corrosion.</p>

- Q: Can someone please explained what aluminum reacts slowly with dilute acided?Thank you!

- rethink your question, is non sensical at this point.

- Q: Can aluminum sheets be used for balcony railings?

- Indeed, balcony railings can be constructed using aluminum sheets. Aluminum is widely favored for balcony railings because of its lightweight properties, durability, and resistance to corrosion. This adaptable material can be effortlessly molded into various shapes and designs, making it suitable for a range of architectural styles. Moreover, aluminum railings necessitate minimal upkeep and can endure inclement weather conditions, rendering them an astute and enduring selection for balcony railings.

- Q: How is an aluminum sheet manufactured?

- An aluminum sheet is manufactured through a process called rolling, where a large ingot of aluminum is heated and passed through a series of rollers to reduce its thickness and increase its length. This continuous rolling process is repeated until the desired thickness is achieved, and the aluminum sheet is then cut into various sizes and shapes.

- Q: How is the thickness of an aluminum sheet measured?

- The thickness of an aluminum sheet is typically measured using a tool called a micrometer. This handheld device applies pressure to the sheet and displays the measurement in millimeters or inches on a digital or analog gauge.

- Q: What is the weight of an aluminum sheet?

- The weight of an aluminum sheet can vary depending on its dimensions and thickness. Aluminum is a lightweight material, so sheets made from it generally have a relatively low weight compared to other metals. To determine the weight of an aluminum sheet, you would need to know the length, width, and thickness of the sheet. By multiplying the dimensions and the density of aluminum (2.7 g/cm³ or 0.0975 lb/in³), you can calculate the approximate weight of the sheet.

- Q: Are aluminum sheets suitable for aircraft manufacturing?

- Yes, aluminum sheets are widely used in aircraft manufacturing due to their lightweight, high strength-to-weight ratio, excellent corrosion resistance, and good formability.

- Q: Are aluminum sheets suitable for aerospace fuel tanks?

- Yes, aluminum sheets are suitable for aerospace fuel tanks. Aluminum is a commonly used material in the aerospace industry due to its lightweight yet durable properties. It offers a good strength-to-weight ratio, making it ideal for fuel tanks that need to be strong enough to withstand the forces of flight while keeping the overall weight of the aircraft as low as possible. Additionally, aluminum is resistant to corrosion, which is crucial for aerospace fuel tanks as they are exposed to various fuels and environmental conditions. The ease of fabrication and availability of aluminum also make it a cost-effective choice for aerospace applications. Overall, aluminum sheets are a suitable material for aerospace fuel tanks due to their strength, lightweight nature, corrosion resistance, and cost-effectiveness.

- Q: This question asks for a list of various types of aluminum sheets that can be used for decorative purposes.

- <p>Aluminum sheets are popular for decorative purposes due to their durability and versatility. The main types include: 1) Embossed Aluminum Sheets, which feature a textured surface for a unique look; 2) Perforated Aluminum Sheets, with holes of various sizes for a distinctive pattern; 3) Mirror Finish Aluminum Sheets, offering a reflective, shiny appearance; 4) Anodized Aluminum Sheets, which have a protective oxide layer for enhanced color and durability; 5) Brushed Aluminum Sheets, with a satin-like finish; 6) Color Coated Aluminum Sheets, available in a wide range of colors; 7) Composite Aluminum Panels, which combine aluminum with other materials for added strength and design options. Each type offers specific aesthetic and functional benefits for various decorative applications.</p>

- Q: Can the aluminum sheets be used for roofing or siding purposes?

- Yes, aluminum sheets can be used for roofing or siding purposes. Aluminum is a durable and lightweight material that is resistant to rust and corrosion, making it a suitable choice for both roofing and siding applications.

Send your message to us

Aluminium Tear Plates, Bright Diamond

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords