Rippled Aluminum Sheets for Roofs - Bright Diamond Aluminium Chequer Plate for Toolbox

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Bright Diamond Aluminium Chequer Plate for Toolbox

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Bright Diamond Aluminium Chequer Plate for Toolbox

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Bright Diamond Aluminium Chequer Plate for Toolbox

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

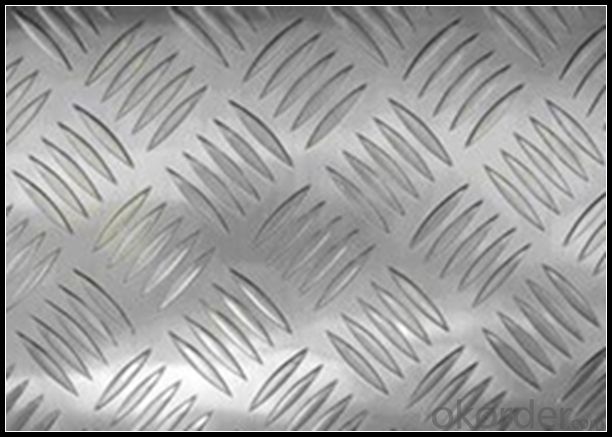

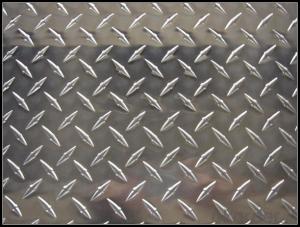

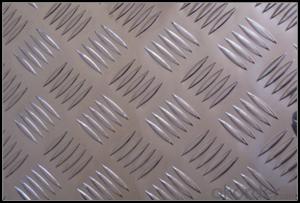

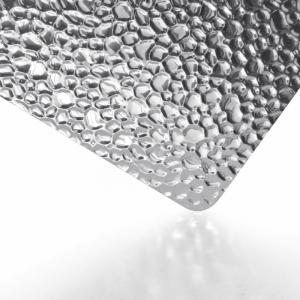

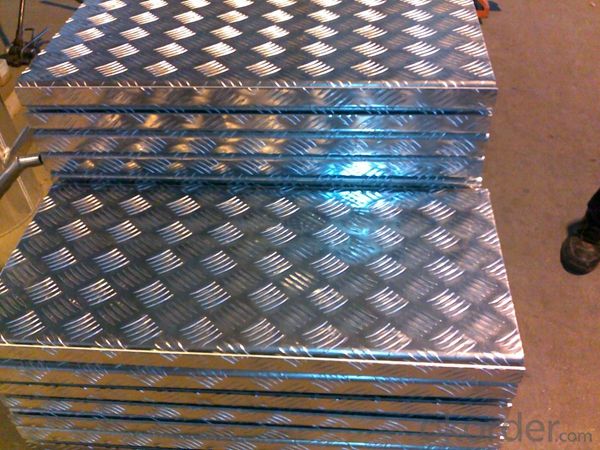

5. Image of Bright Diamond Aluminium Chequer Plate for Toolbox

6. Package and shipping of Bright Diamond Aluminium Chequer Plate for Toolbox

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: is general aluminum sheet fire-proof?

- general aluminum sheet is less fireproof than tinfoil.

- Q: As for graphite and aluminum sheet, which one has a better thermal conductivity?

- aluminum sheet

- Q: Can 101 aluminum sheets be CNC machined?

- Yes, 101 aluminum sheets can be CNC machined. CNC machining is a versatile and precise manufacturing process that is commonly used for aluminum materials. The process involves the use of computer-controlled machines to remove material from the aluminum sheets, allowing for intricate and accurate cuts, holes, and shapes to be created. The specific alloy designation of 101 aluminum sheets does not pose any limitations on their CNC machinability. However, it is important to consider factors such as cutting parameters, tool selection, and feed rates to ensure optimal results when machining aluminum sheets.

- Q: This question asks for methods to clean aluminum sheets to preserve their appearance.

- <p>To clean aluminum sheets and maintain their appearance, follow these steps: 1. Use a mild detergent mixed with warm water to create a cleaning solution. 2. Gently scrub the aluminum sheets with a soft cloth or sponge to avoid scratching the surface. 3. Rinse thoroughly with clean water to remove any detergent residue. 4. Dry the sheets immediately with a soft, dry cloth to prevent water spots. 5. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. 6. Avoid using harsh chemicals or abrasive materials that can damage the aluminum's finish. Regular cleaning will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: I need help with this question for a report i'm doing, it's about recycling aluminium, please could you give me some reasons why to recycle aluminium and eg.saves energy, and how it does eg. saves energy by...Thanks a lot this will help me loads.P.S this is just a report for my science project.

- Well aluminium is a common metal and throwing it away fills up land fills. Recycling the metal means less mining and ripping up the earth.

- Q: What are the different methods of surface cleaning for aluminum sheets?

- There are several methods of surface cleaning for aluminum sheets, each with its own advantages and suitability for different types of cleaning needs. 1. Mechanical Cleaning: This method involves using mechanical abrasion techniques to remove dirt, stains, and oxidation from the surface of aluminum sheets. It can be done using brushes, abrasive pads, sandpaper, or a wire brush. Mechanical cleaning is effective for removing heavy dirt or oxidation, but it may leave scratches on the surface if not done carefully. 2. Chemical Cleaning: Chemical cleaning involves the use of specific cleaning agents or solutions that are designed to dissolve or remove dirt, grease, oil, or other contaminants from aluminum surfaces. These cleaning agents can vary depending on the type of dirt or stain being removed. For example, alkaline cleaners are effective for removing oil and grease, while acidic cleaners can remove mineral deposits or oxidation. It is important to follow the manufacturer's instructions and safety precautions when using chemical cleaners. 3. High-Pressure Water Cleaning: This method utilizes a high-pressure water jet to clean the aluminum surface. The force of the water helps to dislodge dirt or grime from the sheet. High-pressure water cleaning is particularly useful for removing loose debris or light dirt from larger areas. However, it may not be suitable for heavily soiled or oxidized surfaces. 4. Steam Cleaning: Steam cleaning involves using high-temperature steam to remove dirt, grime, or other contaminants from aluminum sheets. The steam helps to loosen the dirt, making it easier to wipe or rinse away. Steam cleaning is effective for removing grease, oil, or other stubborn stains. It is a versatile method that can be used on both small and large surfaces. 5. Electrolytic Cleaning: Electrolytic cleaning is a specialized method that uses an electric current to remove contaminants from the aluminum surface. The aluminum sheet is immersed in a cleaning solution, and an electric current is passed through it. This causes the contaminants to be attracted to a sacrificial electrode, leaving the aluminum sheet clean. Electrolytic cleaning is effective for removing heavy oxidation or corrosion, but it requires specialized equipment and expertise. It is important to consider the specific cleaning requirements, the condition of the aluminum sheet, and the desired level of cleanliness when choosing the appropriate method of surface cleaning. It is also advisable to test the chosen method on a small, inconspicuous area first to ensure compatibility and avoid any potential damage to the aluminum sheet.

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications, including shelving. It offers strength and stability while being easy to clean and maintain. Additionally, aluminum's versatility allows for customization and modification to fit specific storage needs.

- Q: What is the lifespan of the aluminum sheets?

- The durability and longevity of aluminum sheets can differ due to various factors, including the aluminum's quality, the usage environment, and the level of maintenance provided. Despite this, aluminum sheets are renowned for their long-lasting nature. On average, these sheets endure for approximately 20 to 30 years, but by ensuring proper care and maintenance, their lifespan can surpass this estimate. To extend the longevity of aluminum sheets, it is beneficial to regularly clean them, shield them from severe weather conditions, and prevent exposure to corrosive substances.

- Q: Can aluminum sheets be used for decorative purposes?

- Certainly, decorative purposes can indeed be served by aluminum sheets. Aluminum, as a versatile and lightweight material, lends itself easily to manipulation into various shapes, sizes, and designs. It can be painted, coated, or anodized with a multitude of colors to suit any aesthetic preference. In the realm of decoration, aluminum sheets prove useful as panels, signage, wall cladding, ceiling tiles, and even in furniture design. Moreover, aluminum's resistance to corrosion renders it a durable choice for both indoor and outdoor applications. Furthermore, its reflective surface adds a sleek and modern touch to any space. In summary, aluminum sheets offer a vast array of possibilities for incorporating decorative elements into any project.

- Q: Can aluminum sheets be used in automotive applications?

- Yes, aluminum sheets can be used in automotive applications. Aluminum is a lightweight and durable material that offers a variety of benefits for automotive manufacturing. It is commonly used in the production of car bodies, hoods, doors, roofs, and other components. The use of aluminum sheets in automotive applications helps to reduce the overall weight of the vehicle, which improves fuel efficiency and performance. Additionally, aluminum has excellent corrosion resistance properties, making it ideal for withstanding harsh weather conditions and road salt exposure. Furthermore, aluminum can be easily formed and shaped, allowing for complex designs and intricate detailing on automotive parts. Overall, the use of aluminum sheets in automotive applications contributes to the production of lighter, more fuel-efficient, and aesthetically appealing vehicles.

Send your message to us

Rippled Aluminum Sheets for Roofs - Bright Diamond Aluminium Chequer Plate for Toolbox

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords