Printed Aluminum Sheets - Bright Diamond Aluminium Chequer Plate for Boat Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Bright Diamond Aluminium Chequer Plate for Boat Panel

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Bright Diamond Aluminium Chequer Plate for Boat Panel

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Bright Diamond Aluminium Chequer Plate for Boat Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

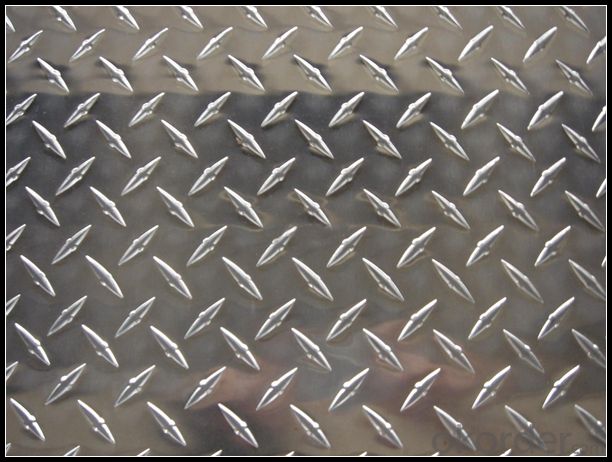

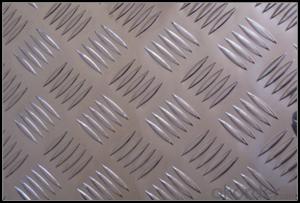

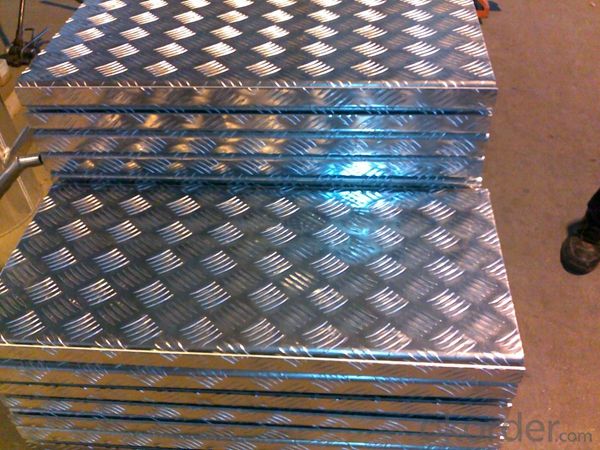

5. Image of Bright Diamond Aluminium Chequer Plate for Boat Panel

6. Package and shipping of Bright Diamond Aluminium Chequer Plate for Boat Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How does aluminum sheet perform in high-pressure applications?

- Due to its inherent properties, aluminum sheet is exceptionally effective in high-pressure applications. Its impressive strength-to-weight ratio makes it a suitable option for withstanding high-pressure environments. Additionally, aluminum exhibits excellent corrosion resistance, a crucial feature when dealing with high-pressure conditions that involve exposure to moisture or aggressive chemicals. Moreover, aluminum sheet is highly malleable, allowing it to be shaped and formed into various configurations to meet the specific requirements of high-pressure applications. Its flexibility enables it to endure the forces and stresses exerted during high-pressure processes without compromising its structural integrity. Furthermore, aluminum demonstrates good thermal conductivity, which aids in dissipating heat generated by high-pressure systems. This characteristic helps prevent overheating and ensures efficient operation. However, it is important to consider that the performance of aluminum sheet in high-pressure applications can be influenced by factors such as sheet thickness and alloy composition. Therefore, it is crucial to carefully select the appropriate grade and thickness of aluminum sheet based on the specific requirements and operating conditions of the high-pressure application. In conclusion, aluminum sheet is a dependable and efficient choice for high-pressure applications due to its strength, corrosion resistance, malleability, thermal conductivity, and overall performance under demanding conditions.

- Q: The corrosion of the aluminum sheet that I request is friction during operation, not the surface of the container after the passivation of the surface of the container containing sulfuric acid. I'd like to use the evaporating plate, the evaporator fin and so on for the cooling in the quick freezing equipment. The ice of ice making machine is attached to the aluminum plate after anodic oxidation or passivation. When it is peeled off, it will cause friction to the surface of the aluminum plate and block the passivation layer, which will make the aluminum plate easier to corrode.

- Directly on the surface coating H2SO4Because the AL and H2SO4 react to produce a dense oxide film that prevents corrosion again, the barrel containing sulfuric acid can be made from AL

- Q: Can aluminum sheets be perforated?

- Yes, aluminum sheets can be perforated. Perforation is a process that involves creating holes or punctures in a material, and it can be done on various types of metals, including aluminum.

- Q: What are the advantages of using aluminum sheet in construction?

- Using aluminum sheet in construction offers several benefits. Firstly, its lightweight composition makes it easy to handle and transport on construction sites, reducing the need for heavy machinery and improving efficiency, ultimately leading to cost savings. Secondly, aluminum exhibits exceptional resistance to corrosion, unlike other metals such as steel, making it a durable and suitable material for outdoor applications like roofing or cladding. Additionally, aluminum's versatility allows for easy shaping and forming into various sizes and profiles, providing architects and engineers with greater design flexibility to create innovative and unique structures. Moreover, aluminum is a sustainable choice as it is 100% recyclable, helping reduce waste and minimize the carbon footprint. Furthermore, it possesses excellent thermal and electrical conductivity properties, reflecting heat and light to maintain comfortable indoor temperatures and reduce energy consumption. It also serves as an excellent conductor of electricity, making it ideal for electrical wiring and building components. Lastly, though aluminum may have a higher initial cost, its low maintenance requirements and long lifespan make it cost-effective in the long run. Structures made with aluminum sheet do not require regular painting or upkeep, saving both time and money. In conclusion, the advantages of utilizing aluminum sheet in construction encompass its lightweight nature, corrosion resistance, versatility, sustainability, thermal and electrical conductivity, and cost-effectiveness, making it highly desirable for a wide array of construction applications.

- Q: What is the tensile strength of aluminum sheets?

- The tensile strength of aluminum sheets may differ based on the specific alloy and temper of the material. On average, aluminum sheets generally exhibit a tensile strength between 10,000 and 45,000 pounds per square inch (psi). It should be noted that the tensile strength of aluminum sheets varies depending on the grade and thickness. Moreover, factors like heat treatment, processing, and alloy composition can influence the tensile strength of aluminum sheets. Hence, consulting the manufacturer's specifications or conducting specific tests becomes necessary to ascertain the exact tensile strength of a particular aluminum sheet.

- Q: This question asks whether it is possible to utilize stamped or embossed aluminum sheets for a specific project.

- <p>Yes, you can use stamped or embossed aluminum sheets in your project. These sheets are known for their strength, durability, and lightweight properties, making them ideal for various applications such as construction, automotive, and aerospace. Stamped aluminum sheets are formed by pressing the material into a specific shape, while embossed sheets have a raised pattern. Both types offer design flexibility and can be customized to meet specific project requirements. Ensure that the aluminum sheets you select meet the necessary specifications for your project, such as thickness, strength, and finish.</p>

- Q: Are aluminum sheets suitable for architectural canopies?

- Yes, aluminum sheets are suitable for architectural canopies. Aluminum is a lightweight and durable material that offers excellent weather resistance and structural integrity, making it an ideal choice for canopies. It can be easily fabricated into various shapes and sizes, allowing for versatile and aesthetically pleasing designs. Additionally, aluminum can be coated or anodized to enhance its appearance and protect it from corrosion, further enhancing its suitability for architectural canopies.

- Q: I am doing some exam review and do not know how to do these...Calculate the number of Nitrate ions in 3.99 g or aluminum nitrate.

- ? number of NO3 = 3.99g AlNO3 x(1mol AlNO3/212.996 g AlNO3)x(1mol NO3/1mol AlNO3)x(6.02*10^23 number of NO3/1mol NO3)=11*10^21 number of NO3

- Q: Are the aluminum sheets suitable for manufacturing power distribution panels?

- Yes, aluminum sheets are suitable for manufacturing power distribution panels. Aluminum is a lightweight, durable, and corrosion-resistant material that makes it an ideal choice for various industrial applications, including power distribution panels. Aluminum sheets can withstand high electrical currents while effectively dissipating heat, ensuring the safe and efficient distribution of power. Additionally, aluminum is readily available and cost-effective compared to other materials such as copper. Therefore, aluminum sheets are a suitable choice for manufacturing power distribution panels.

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

Send your message to us

Printed Aluminum Sheets - Bright Diamond Aluminium Chequer Plate for Boat Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords