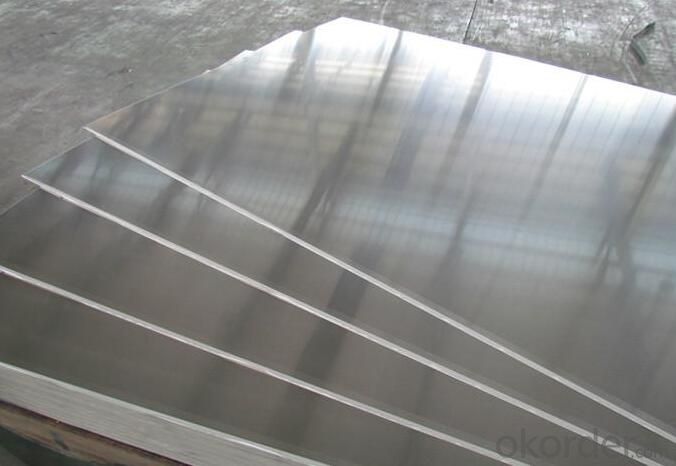

Mill Finished Diamond Plate Aluminum Sheets for Decoration Material Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finished Aluminium Plate For Decoration Material Production

Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

A1050,A1060, A1070, A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

3A21, A3003, A3105, A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

A5052, A5005, A5083, A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

A6061, A6082, A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

Packing: Export wooden pallets. The bundle weight not exceed 2MT. Loading: by 1x20GP, 1X20GP can load about 18MT | |||||

Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

MOQ | 5 tons | ||||

Payment term | T/T,L/C | ||||

Delivery Time | 20-30 days after 30% T/T payment or receiving L/C copy | ||||

Kind attention: Specifications can be customized as the customer’s requirements. | |||||

PVDF color pre coated aluminum coils/ sheets:

It is well known that fluorocarbon lacquer coating (PVDF coating) owes the best acid resistant/alkali and temperature tolerant capabilities of all painting materials. Being the best quality of precoated aluminum, PVDF coated coils are especially suitable for outdoor roofing walls and ceiling manufacturing.

Polyester (PE) color pre coated aluminum coils/ sheets :

Using high-grade polyester lacquer coating material, the finished coated coils are with delicate color uniform texture, color and diverse. It is the most popular and most common used materials in decorative usage. The PE coated aluminum are widely used in ACP( aluminum composite panel ) production and indoor ceiling usage.

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

- Q: Are aluminum sheets suitable for insulation and soundproofing?

- Yes, aluminum sheets can be suitable for insulation and soundproofing purposes. Aluminum is a lightweight, durable, and highly reflective material that can effectively block heat and sound transmission. When used as insulation, aluminum sheets can act as a radiant barrier, reflecting heat away from the insulated space and helping to maintain a comfortable temperature. Furthermore, aluminum sheets can also be used as a soundproofing material to reduce the transmission of noise. The dense structure of aluminum helps to absorb and dampen sound waves, making it an effective solution for minimizing noise pollution. Additionally, aluminum sheets are resistant to corrosion and moisture, making them suitable for both indoor and outdoor applications. Overall, aluminum sheets provide a cost-effective and efficient solution for insulation and soundproofing needs.

- Q: What is the electrical resistivity of aluminum sheets?

- Aluminum sheets usually exhibit an electrical resistivity within the range of 2.65 to 2.82 micro-ohm centimeters. Nevertheless, it should be emphasized that the precise resistivity is subject to variation based on factors such as the alloy composition, thickness, temperature, and other considerations.

- Q: Are 101 aluminum sheets suitable for outdoor signage?

- Yes, 101 aluminum sheets are suitable for outdoor signage. They are corrosion-resistant, durable, and can withstand various weather conditions, making them a suitable choice for outdoor applications.

- Q: Can 101 aluminum sheets be perforated?

- Yes, 101 aluminum sheets can be perforated.

- Q: I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum?I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save some money.. so what are the pros - cons?

- This Site Might Help You. RE: aluminum boat vs fiberglass? I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum? I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save...

- Q: Is it suitable to use aluminum sheets in outdoor settings where they will be subjected to weather conditions?

- <p>Yes, aluminum sheets can be used for outdoor applications, even when exposed to weathering. Aluminum is a durable and corrosion-resistant material, which makes it suitable for outdoor use. It does not rust like iron or steel and can withstand various weather conditions. However, it's important to use aluminum alloys specifically designed for outdoor use, and to apply protective coatings or finishes to enhance its resistance to weathering and extend its lifespan.</p>

- Q: What are the different types of protective films available for aluminum sheets?

- There are several types of protective films available for aluminum sheets, including adhesive-backed films, peelable films, electrostatic films, and spray-on films. These films provide temporary protection against scratches, abrasions, and other damage during transportation, storage, and fabrication processes.

- Q: What is the thermal expansion coefficient of aluminum sheets?

- The thermal expansion coefficient of aluminum sheets typically ranges from 22 to 24 x 10^-6 per degree Celsius.

- Q: Okay guys i need to rapir a crack on an aluminum pipe , would durafix do the job ?? If so where can i get this durafix ? at my local home depot ?

- You can order it online. It works acceptably well, though it's obviously not as good as bona fide welding. You can also use tin+zinc hard solder, for this- you need a special soldering flux specifically desgined for soldering aluminum. You can order aluminum soldering kits online also. You might also be able to find a welding supply store in your area and they would probably carry Al soldering kits in stock. I feel that soldering would probably give you more reliable results in this case. Solder is a lot thinner and has better wetting action than the durafix alloy. This means that solder will be more likely to flow into the crack itself and completely seal it, whereas the durafix may simply lie on top of the crack. I think durafix technically qualifies as brazing since it melts at a lower temperature than the aluminum itself. However, you will also need to buy a propane torch, that'll probably cost around 30-40$ at a hardware store. Plus the cost of the brazing metal which is around 12-20$. so you're looking at 30-50$ probably. This might be a bit of a fun- DIY project if you feel it's worth some time and practice on your part. On the other hand any welding shop can simply TIG weld your pipe for about 20$ and it will only take them a few minutes. So having the professionals do it will be much faster, cheaper, and almost certainly a better quality repair than if you attempted to DIY.

- Q: What specific tools or equipment are necessary for working with aluminum sheets?

- <p>Working with aluminum sheets typically requires a few specialized tools and equipment. These include a metal cutting saw for precise cuts, a metal file or sandpaper for smoothing edges, a metal shear for cutting, and a drill with metal bits for making holes. A roller or bending brake is useful for shaping the sheets, and a T-square or straight edge is important for marking straight lines. Safety equipment such as gloves, goggles, and a dust mask are also essential to protect against sharp edges and metal dust.</p>

Send your message to us

Mill Finished Diamond Plate Aluminum Sheets for Decoration Material Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords