High Quality Household Aluminum Foil Strips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

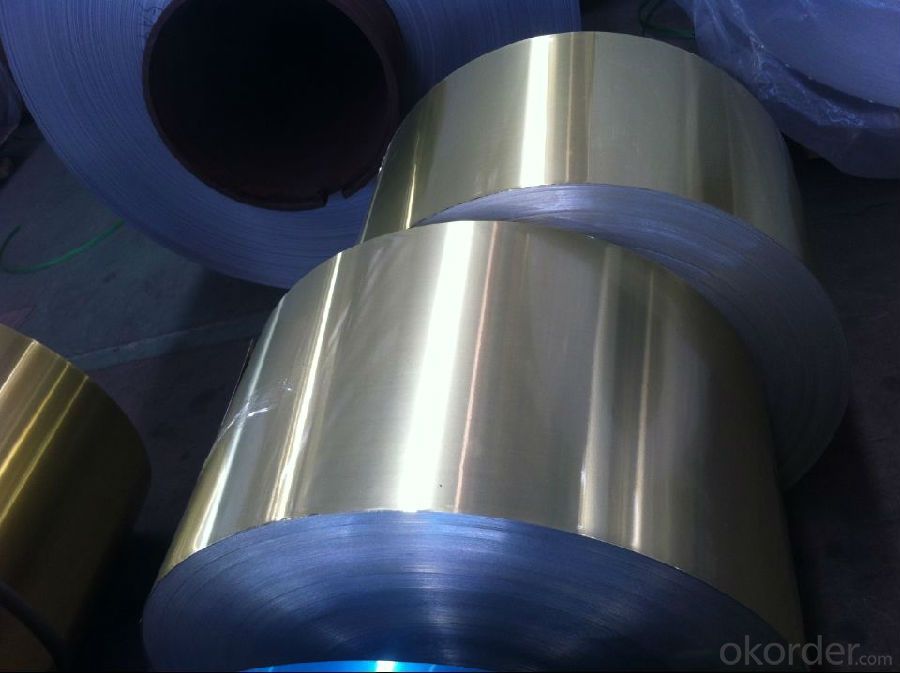

1. Structure of Aluminum Foil for Household Usage with High Quality Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields. Our aluminum foils are with high quality. They can be widely used in household field, such as food, cookware. Our aluminum foils for household meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. We have very strict inspection management. Test equipments include optical thickness gauge, cupping test machine, mettle Toledo, tensile-strength tester, busting strength tester, elongation tester, etc. 2.Main Features of Aluminum Foil for Household Usage with High Quality Moisture resistant Light and easy for installation Heat preservation Low thermal conductivity Durable and corrosion resistance High heat reflection Energy Saving 3. Aluminum Foil for Household Usage with High Quality Images 4.Specification of Aluminum Foil for Household Usage with High Quality Alloy 8011/1235 Temper: O Thickness: 0.009mm-0.04mm (+/-6%) Width: 200mm- 720mm Standard: GB/T3198/ASTM-B209/EN546 Special Specification is available on customer’s requirement 5.FAQ A.What about inspections to guarantee quality? For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods. With requirement of customers, we also can arrange the third party inspection. B.What about delivery? We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity. C.What is the MOQ? 5 tons for each size. D. Where have you exported? We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Is it possible to use aluminum strips for the purpose of covering the interior walls of a building?

- <p>Yes, aluminum strips can be used for interior wall cladding. They are known for their durability, low maintenance, and resistance to moisture and corrosion, making them suitable for various interior applications. Aluminum strips are lightweight, easy to install, and can be used in both residential and commercial settings. They come in various finishes and colors, allowing for customization to match the desired aesthetic. However, it's important to ensure proper installation and adherence to building codes and safety standards.</p>

- Q: Explain how aluminum strips can impact the waterproofing process and their role in construction.

- <p>Aluminum strips play a crucial role in waterproofing by serving as a barrier against water penetration. They are often used in construction to seal joints and seams where water could potentially infiltrate. These strips are durable, corrosion-resistant, and flexible, making them ideal for maintaining a watertight seal even under fluctuating temperatures and structural movements. They can be used in conjunction with other waterproofing materials such as sealants and membranes to create a robust defense against water damage. By preventing water from entering buildings or structures, aluminum strips help to protect against moisture-related issues like mold, structural decay, and deterioration, thereby enhancing the longevity and integrity of the construction.</p>

- Q: This question asks about the environmental effects of utilizing products made from recycled aluminum.

- <p>Using recycled aluminum products has several positive environmental impacts. It conserves natural resources by reducing the need for mining new aluminum, which is energy-intensive and can lead to habitat destruction. Recycling aluminum uses only 5% of the energy required to produce aluminum from raw materials, significantly reducing greenhouse gas emissions. Additionally, it decreases waste in landfills, as aluminum is infinitely recyclable without losing quality. This process also reduces water pollution and soil degradation associated with mining activities. Overall, the use of recycled aluminum products contributes to a more sustainable and environmentally friendly economy.</p>

- Q: This question asks for an explanation of the various kinds of aluminum strips that exist, which could include their properties, uses, and any other distinguishing features.

- <p>Aluminum strips come in various types, differentiated by their alloy composition, thickness, width, and temper. Common types include 1000 series strips, which are 99% pure aluminum, known for their high thermal and electrical conductivity. 3000 series strips, like 3003 alloy, offer good formability and are used in cooking utensils and chemical equipment. 5000 series strips, such as 5052, are known for their strength and are used in marine applications and aircraft structures. 6000 series strips, like 6061, are heat-treatable and used in construction and automotive parts. Each type has specific properties that make them suitable for different applications, from lightweight structures to high-strength components.</p>

- Q: What benefits does using aluminum strips provide compared to other materials?

- <p>Aluminum strips offer several advantages over other materials, including high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. They are lightweight, which is beneficial for reducing the weight of structures or products. Aluminum's resistance to corrosion means it requires less maintenance and has a longer lifespan. Additionally, its thermal conductivity makes it suitable for applications where heat transfer is important, such as in heat sinks or cookware. Aluminum strips are also easy to work with, allowing for easy fabrication and customization, and they are cost-effective, making them a popular choice in various industries.</p>

- Q: Process and troubleshooting of aluminium strip type loose heat aluminium pipe

- Generally speaking, computer failures include two major categories of hardware damage and software program errors. The former is a hard fault, and the latter is a soft fault. Hard faults can be divided into three major categories: device faults, mechanical failures and human failures. The device is mainly fault components, connectors and printing plate caused by mechanical failure; mainly external device error, such as keyboard failure; human error is mainly caused by the machine does not meet the operation requirements or environmental conditions caused by improper operation.

- Q: This question asks for guidance on ensuring the correct installation and ongoing maintenance of an aluminum strip.

- <p>To ensure your aluminum strip is properly installed and maintained, follow these steps: First, ensure the surface where the strip will be installed is clean and free of debris. Use a high-quality adhesive that is compatible with aluminum for installation. Apply the adhesive evenly and press the strip firmly into place. Check for any gaps or misalignments and correct them immediately. For maintenance, regularly clean the strip to prevent dirt buildup. Avoid using harsh chemicals that could damage the aluminum. Inspect the strip periodically for signs of wear or damage and repair or replace as necessary. Proper installation and regular maintenance will extend the life of your aluminum strip and ensure its functionality.</p>

- Q: Is it possible to use aluminum strips as a roofing material in regions with cold weather conditions?

- <p>Yes, aluminum strips can be used for roofing in cold climates. Aluminum is a durable and lightweight material that is resistant to corrosion and weathering, making it suitable for various climates, including cold ones. It doesn't rust and can withstand heavy snow loads. However, it's important to consider the thermal properties of aluminum, as it conducts heat and cold efficiently, which may necessitate additional insulation to maintain the desired indoor temperature. Additionally, proper installation and underlayment are crucial to prevent moisture and heat loss.</p>

- Q: This question asks for a list of various types of aluminum strips that are specifically used for exterior applications.

- <p>Aluminum strips used for exterior applications come in various types, each serving specific purposes. These include: 1) Architectural Aluminum Strips, used for facades and building exteriors due to their durability and weather resistance. 2) Anodized Aluminum Strips, which offer enhanced corrosion resistance and a wide range of colors for aesthetic appeal. 3) Extruded Aluminum Strips, known for their strength and customizability, suitable for structural applications. 4) Embossed Aluminum Strips, which provide a textured surface for improved grip or decorative purposes. 5) Heat Insulating Aluminum Strips, used to reduce heat transfer in exterior applications. 6) Reflective Aluminum Strips, used for safety markings or to enhance visibility in outdoor settings. Each type is chosen based on the specific requirements of the project, such as strength, appearance, and environmental conditions.</p>

- Q: What are the elements or materials that make up aluminum strips?

- <p>Aluminum strips are primarily composed of aluminum, which is a lightweight and malleable metal with the chemical symbol Al and atomic number 13. They may also contain trace amounts of other elements such as copper, magnesium, manganese, silicon, and zinc, depending on the specific alloy. These additional elements are often added to enhance properties such as strength, corrosion resistance, or workability. Pure aluminum is soft and not commonly used for strips; instead, aluminum alloys are preferred for their improved characteristics.</p>

Send your message to us

High Quality Household Aluminum Foil Strips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords