Wholesale High-Quality Aluminum Diamond Plate Sheets for Printing - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Diamond Plate Description:

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment

2.Main Features of Aluminum Diamond Plate :

Low density, light in weight

Anti-corrosion

Strong

Malleable

Naturally good looking

Recyclable

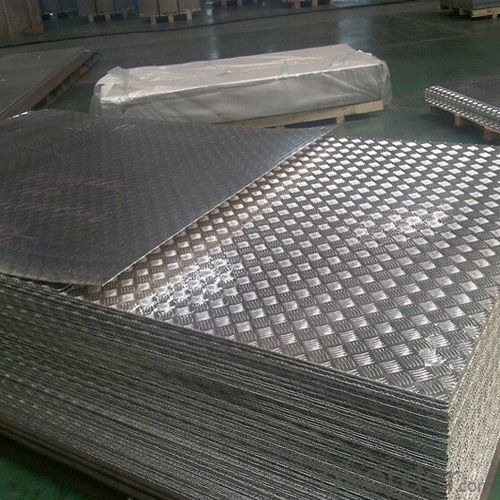

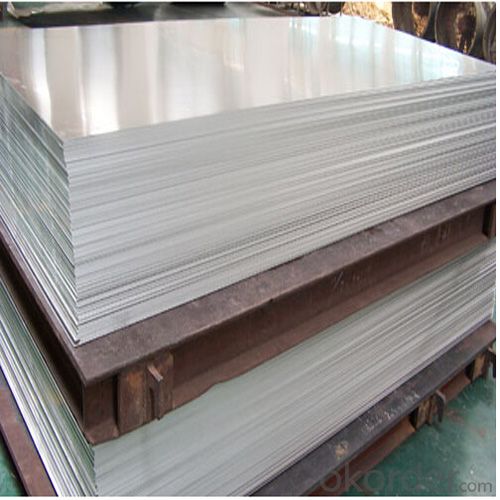

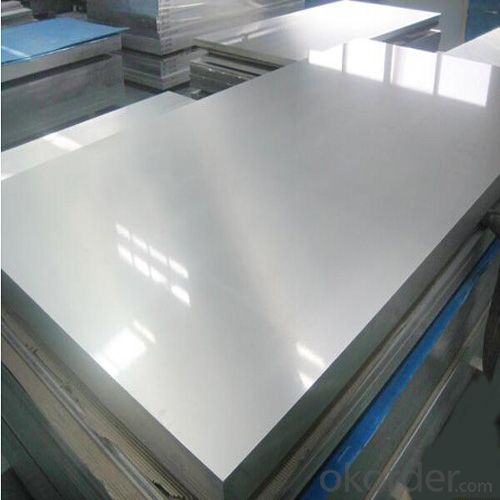

3. Aluminum Diamond Plate Images:

4. Aluminum Diamond Plate Specification:

Product Name | Alloy | Temper | Thickness | Width |

Anodized Aluminum Sheet | 1060,1070,1100,3003,3004,3005, 5083,5086,5154,6063,7075,8011 | H1X,H2X,H3X,O,HXXX | 0.20-10mm | 600-2000mm |

Aluminum Tread Plate | 1060,1100,3003,3105, 5052,5083,5754,6061, etc. | H12,H14,H16,H18,H22,H24, H26,H32,H34,H36,H38,O, etc. | 1-6mm | 1600mm max |

Aluminum Checker Plate | 1060,1100,3003,3105, 5052,5083,5754,6062, etc. | H12,14,H16,H18,H22,H24, H26,H32,H34,H36,H39,O, etc. | 1-7mm | 1600mm max |

Aluminum Diamond Plate | 1060,1100,3003,3105, 5052,5083,5754,6063, etc. | H12,H14,H16,H18,H22,H24, H26,H32,H34,H36,H40,O, etc. | 1-8mm | 1600mm max |

Embossed Aluminum Sheet | 1060,1100,3003,5000,2A12, 6061,6063,7075,8011, etc. | T6,O,H12,H14,H16, H18,H22,H24,H32, etc. | 0.2-200mm | 200-2200mm |

Copolymer Coated Aluminum Sheet | 1145,8011 | soft | 0.15-0.20mm (Coating thickness: 0.015mm) | 15-2400mm |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Yes, aluminum sheets are suitable for use in HVAC systems. They offer several advantages such as high thermal conductivity, corrosion resistance, and lightweight nature, making them ideal for efficient heat transfer and durability in HVAC applications.

- Q: Can aluminum sheets be perforated?

- Yes, aluminum sheets can be perforated. Perforation is a process that involves punching holes or creating a pattern of holes in a material. Aluminum is a versatile and malleable metal that can be easily perforated using various methods such as punching, drilling, or laser cutting. Perforating aluminum sheets can serve multiple purposes such as allowing for airflow, reducing weight, enhancing aesthetics, or creating filtration systems. The size, shape, and arrangement of the perforations can be customized to meet specific requirements and design preferences. Overall, aluminum sheets can be effectively perforated to enhance their functionality and visual appeal.

- Q: Are 101 aluminum sheets readily available in the market?

- Yes, 101 aluminum sheets are readily available in the market. These sheets are commonly used in various industries and applications due to their excellent corrosion resistance, high strength, and light weight. They can be easily found in metal supply stores, online marketplaces, and specialized aluminum suppliers. Additionally, 101 aluminum sheets are available in different sizes, thicknesses, and finishes, allowing customers to choose the most suitable option for their specific requirements.

- Q: Can the aluminum sheets be used for manufacturing audio amplifier cases?

- Certainly, audio amplifier cases can be manufactured using aluminum sheets. The utilization of aluminum as casing material in audio equipment is highly favored owing to its remarkable combination of lightweight and resilient characteristics. It offers exceptional heat dispersion, a critical aspect for audio amplifiers that generate heat while in operation. Additionally, aluminum can be effortlessly machined and shaped into diverse forms, facilitating customization and aesthetic considerations in the design of the amplifier case. In conclusion, aluminum sheets are a fitting choice of material for the production of audio amplifier cases.

- Q: What is the weight of aluminium plate now?

- Is different according to the different density of aluminum alloy content, such as a series of pure aluminum and aluminum density is 2.71, which is close to that of 1060 Aluminum, 1050.1100 series of density is 2.71. and 3003 aluminum plate belongs to the aluminum manganese alloy, manganese alloy belongs to high density alloy, so the density is higher than that of 3003 aluminum plate 1060. and 5052 series aluminum magnesium alloy, magnesium alloy alloy belongs to low density, so the density of 2.68.5083 5052 aluminium alloy aluminum magnesium alloy containing the content because of the high price (4.5%) so 5083 aluminum density of 2.66. 2 series and 7 Series (such as 7075) belongs to high density alloy (copper and zinc) so high density.

- Q: What industries use aluminum sheets?

- Aluminum sheets find extensive use across various industries due to their numerous advantageous properties. The automotive industry, in particular, heavily relies on aluminum sheets. With its lightweight yet strong composition, aluminum proves to be an ideal material for manufacturing car bodies and parts. This, in turn, helps reduce vehicle weight, improving fuel efficiency and curbing emissions. Similarly, the aerospace industry also heavily depends on aluminum sheets owing to their high strength-to-weight ratio. Aluminum's suitability for aircraft construction is evident in its usage for airplane frames, wings, and fuselages. The lightweight nature of aluminum contributes to increased fuel efficiency and enables larger payloads. The construction industry is another major consumer of aluminum sheets. Thanks to its corrosion resistance and durability, aluminum serves as an excellent choice for building materials. It finds common application in roofing, siding, windows, doors, and structural components for both residential and commercial construction projects. In the packaging industry, aluminum sheets are extensively utilized for manufacturing beverage cans. Aluminum cans provide a lightweight and portable packaging solution while ensuring product freshness and protection against light and air. Additionally, the electrical industry benefits from the use of aluminum sheets. Aluminum's excellent conductivity makes it well-suited for electrical transmission lines, cables, and wiring. It also finds application in the production of heat sinks and electrical enclosures. Marine industry applications involve aluminum sheets for boat building and ship construction due to their resistance to corrosion in saltwater environments. Furthermore, aluminum sheets play a significant role in the manufacturing of household appliances, such as refrigerators, ovens, and washing machines, owing to their durability, lightweight nature, and heat conductivity properties. In conclusion, the versatility, strength, lightweight nature, and corrosion resistance of aluminum sheets make them indispensable across a wide range of industries, including automotive, aerospace, construction, packaging, electrical, marine, and household appliances.

- Q: What types of bonds can aluminum form: Covalent, Ionic and/or Metallic?Could you post the source, I've been looking for a while now :/

- Aluminum Bonds

- Q: Are the aluminum sheets suitable for manufacturing aircraft interiors?

- Aluminum sheets are an excellent choice for producing aircraft interiors. Not only is aluminum lightweight, but it is also strong and durable, making it perfect for aerospace applications. Its high strength-to-weight ratio allows for the creation of fuel-efficient and lightweight aircraft. Moreover, aluminum sheets are highly resistant to corrosion, which is vital in the aerospace industry. Aircraft interiors are exposed to various environmental factors like humidity and temperature changes. The corrosion resistance of aluminum ensures that the aircraft interior components remain reliable and long-lasting, thereby reducing maintenance and replacement expenses. Additionally, aluminum sheets can be easily fabricated and shaped into different forms. This feature enables the production of intricate and customized aircraft interior components. Aluminum sheets can be effortlessly cut, bent, and welded, offering design flexibility and allowing manufacturers to create visually appealing interior designs. Apart from these technical advantages, aluminum is also an environmentally sustainable material. It is 100% recyclable, making it an eco-friendly option for aircraft interiors. Recycling aluminum requires significantly less energy compared to primary aluminum production, thereby reducing the carbon footprint associated with manufacturing. In conclusion, the combination of its lightweight nature, corrosion resistance, ease of fabrication, and sustainability makes aluminum sheets highly suitable for manufacturing aircraft interiors.

- Q: Is aluminum sheet magnetic?

- No, aluminum sheet is not magnetic. Aluminum is a non-magnetic metal, which means it does not attract or repel other magnetic materials. This is because aluminum does not have magnetic properties and does not contain any magnetic elements. Therefore, if you try to use a magnet on an aluminum sheet, it will not stick or be affected by the magnetic field.

- Q: Over 5 billion aluminum cans are recycled each year. If laid end to end, these cans would form a line reaching from?

- No, Ed. 1 billion seconds = 31.69 years, so it was the spring of 1976. Also 1 billion minutes ago = about 1901.3 years ago, so Christ would have been about 100. But I digress... Anyway, let's say the average aluminum can is 4.9 tall (I measured a Coke can). 5 billion cans would be 24.5 billion inches tall. This would be 386,679 miles. This would be from the Earth to the moon (about 250,000 miles) and halfway back again!

Send your message to us

Wholesale High-Quality Aluminum Diamond Plate Sheets for Printing - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords