Sheets of Aluminum Diamond Plate with Better Discount Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

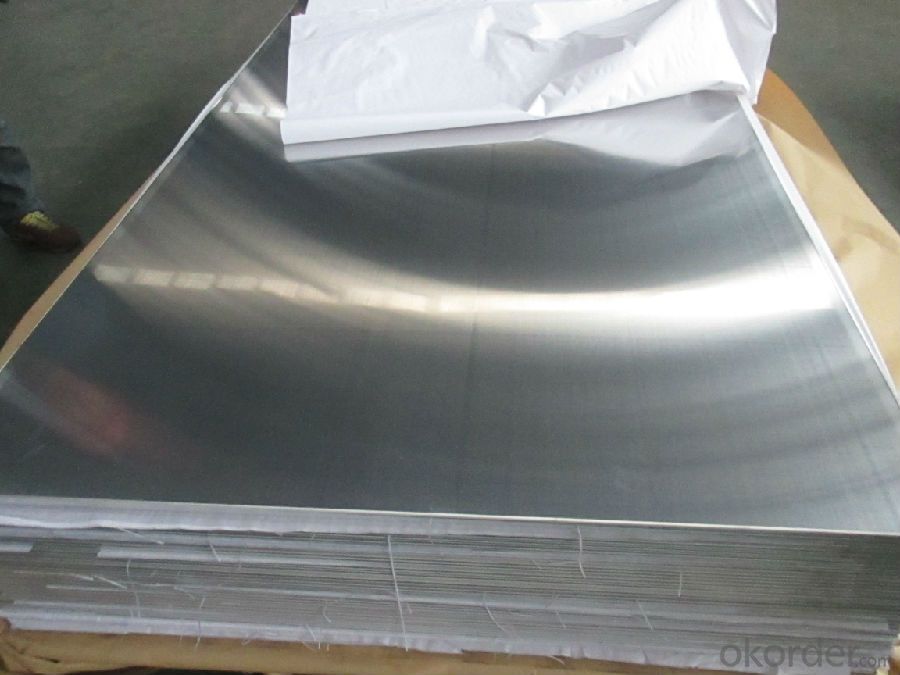

1.Structure of Product Description

Cold rolled aluminum sheet and hot rolled sheet are all widely used in the field of construction field and decoration field, etc. we have different sizes also, There are many different grades, such as: 1000 series, 2000 series, 7000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010,1100, 1060,1050, 2024, 3003, 3005, 3105, 5052,7075, 6063,8011, etc.

The temper is include H14,H44,O, F, H112,H114,etc.

2. Main features of the product

a. Competitive price

b.Frist-Class Service.

c. Shortest service.

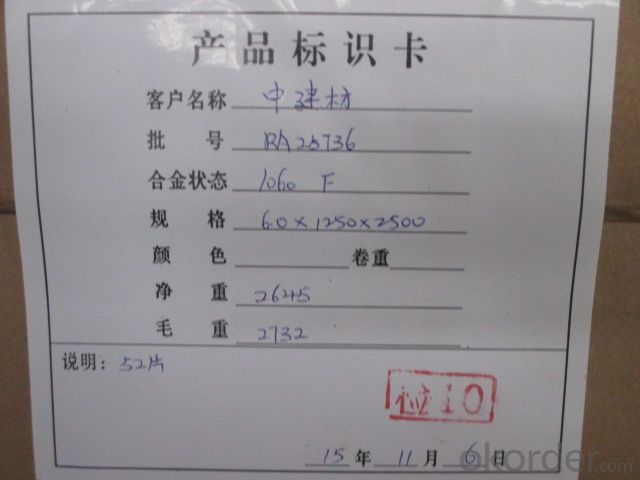

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 500*500,600*600, 700*700, 800*800,900*900, etc.

1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally they are cold rolled and hot rolled and checkered sheet, and mirror finished sheet, etc.

aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Are aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction. Aluminum is a lightweight yet strong material that offers excellent corrosion resistance in marine environments. It is commonly used in the construction of various marine vessels, including boats, ships, and yachts. One of the main advantages of using aluminum sheets in marine vessel construction is their high strength-to-weight ratio. This allows for the construction of lighter vessels, which can result in improved fuel efficiency, increased speed, and better handling. Additionally, the lightweight nature of aluminum makes it easier to transport and maneuver during the construction process. Another key benefit of aluminum sheets for marine vessel construction is their exceptional resistance to corrosion. Aluminum naturally forms a protective oxide layer on its surface, which prevents further oxidation and corrosion. This makes aluminum an ideal choice for marine environments, where vessels are constantly exposed to saltwater, humidity, and other corrosive elements. Furthermore, aluminum sheets can be easily fabricated and welded, providing flexibility in the design and construction of marine vessels. They can be shaped into various forms, allowing for the creation of complex hull structures and interior components. Aluminum also offers good thermal conductivity, which can help regulate temperature in the interior spaces of marine vessels. While aluminum sheets have many advantages for marine vessel construction, it is important to consider certain factors. Aluminum is susceptible to galvanic corrosion when it comes into contact with certain metals, such as steel or bronze. Therefore, proper insulation and anti-corrosion measures should be taken to prevent galvanic corrosion in aluminum-based vessels. In conclusion, aluminum sheets are highly suitable for marine vessel construction. Their lightweight, high strength-to-weight ratio, corrosion resistance, and ease of fabrication make them an ideal choice for building durable and efficient marine vessels. However, proper precautions should be taken to prevent galvanic corrosion when aluminum is used alongside other metals.

- Q: This question asks for a list of aluminum sheet types suitable for exterior applications, indicating a need for knowledge on construction materials.

- <p>Aluminum sheets for exterior use come in various types, each with specific properties and applications. Some common types include: 1. Mill Finish Sheets: These have a natural aluminum finish and are corrosion resistant. 2. Anodized Aluminum Sheets: They offer enhanced durability and resistance to weathering. 3. Painted Aluminum Sheets: These are coated with a protective paint layer for improved aesthetics and weather resistance. 4. Embossed Aluminum Sheets: They provide a textured surface and are used for both aesthetic and functional purposes. 5. Perforated Aluminum Sheets: These have holes and are used for ventilation and light filtration. 6. Aluminum Composite Material (ACM) Sheets: These are lightweight and used for cladding due to their strength and low weight. Each type is chosen based on the specific requirements of the project, such as weather conditions, aesthetic preferences, and structural needs.</p>

- Q: Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be used in food packaging. Aluminum is a common material choice for food packaging due to its excellent barrier properties, durability, and ability to maintain the freshness and quality of food products. It is also lightweight, recyclable, and resistant to moisture, odors, and UV light.

- Q: will it influence powder injection effect after wiping the oil contamination on the surface of aluminum sheet?

- the surface should be kept clean to avoid the influence of oil contamination.

- Q: Can aluminum sheets be used for battery casings?

- Yes, aluminum sheets can be used for battery casings. Aluminum is a commonly used material in the manufacturing of battery casings due to its lightweight, corrosion-resistant, and durable properties. It also allows for efficient heat dissipation, making it suitable for various types of batteries.

- Q: Are aluminum sheets suitable for electrical applications?

- Yes, aluminum sheets are suitable for electrical applications. Aluminum has excellent electrical conductivity, making it a popular choice for various electrical components and wiring. It is lightweight, corrosion-resistant, and can efficiently dissipate heat, making it appropriate for electrical applications where these properties are desired.

- Q: What are the specific rules or benchmarks that must be followed when utilizing aluminum sheets for construction purposes?

- <p>Yes, there are special regulations and standards for using aluminum sheets in construction projects. These include material specifications, thickness, and strength requirements as per the American Society for Testing and Materials (ASTM) standards, such as ASTM B209 for aluminum sheet and plate. Additionally, the International Building Code (IBC) and local building codes provide guidelines for the use of aluminum in construction. These standards cover aspects like fire resistance, structural integrity, and weather resistance. Compliance with these regulations ensures safety, durability, and compliance with construction laws.</p>

- Q: What are the different methods of surface protection for aluminum sheet?

- Some of the different methods of surface protection for aluminum sheet include anodizing, powder coating, painting, and laminating. Anodizing involves creating a protective oxide layer on the surface of the aluminum, which provides corrosion resistance and enhances its appearance. Powder coating involves applying a dry powder coating to the aluminum sheet and then curing it through heat, creating a durable and protective finish. Painting is another method where a liquid paint is applied to the surface of the aluminum sheet, providing both protection and aesthetic appeal. Laminating involves bonding a protective film or sheet onto the surface of the aluminum, offering resistance against scratches, abrasion, and chemical damage. These methods help to preserve the quality and longevity of the aluminum sheet in various applications.

- Q: Are aluminum sheets resistant to abrasion?

- Indeed, aluminum sheets exhibit a general resistance to abrasion. Renowned for its sturdy nature and robustness, aluminum proves impervious to scratches or harm induced by abrasion. Nevertheless, the degree of resistance may fluctuate contingent upon the particular alloy and thickness of the aluminum sheet. Sheets boasting greater thickness and higher alloy content typically offer superior protection against abrasion. Furthermore, the surface finish of the aluminum sheet can also influence its resistance to abrasion. All things considered, aluminum sheets present a dependable option for enduring abrasion in a myriad of applications.

- Q: What are the benefits of using aluminum sheets?

- Using aluminum sheets in various applications offers several advantages. Firstly, aluminum sheets are lightweight, which makes them easy to handle and transport. This is particularly beneficial in industries like aerospace, automotive, and construction, where reducing weight is crucial for better fuel efficiency and overall performance. Secondly, aluminum sheets provide excellent resistance to corrosion. Unlike other metals, aluminum naturally develops a protective oxide layer when exposed to air, preventing further corrosion and enhancing durability. This makes aluminum sheets highly suitable for outdoor applications or in environments with high humidity or corrosive substances. Another advantage of aluminum sheets is their high strength-to-weight ratio. Aluminum is known for its exceptional strength, allowing it to withstand heavy loads or extreme conditions without compromising its structural integrity. This makes it an ideal choice for constructing lightweight yet sturdy structures, such as building facades, vehicles, or industrial equipment. Additionally, aluminum sheets are highly malleable and ductile, meaning they can easily be formed into various shapes and sizes. This flexibility allows for intricate designs and customization, making aluminum sheets highly versatile and adaptable to different manufacturing processes or project requirements. Furthermore, aluminum is a sustainable and environmentally friendly material. It is completely recyclable, meaning it can be reused repeatedly without losing its properties or quality. Recycling aluminum requires significantly less energy compared to primary aluminum production, resulting in reduced carbon emissions and a smaller environmental footprint. Lastly, aluminum sheets exhibit excellent thermal and electrical conductivity properties. This makes them suitable for applications that require efficient heat transfer or electrical conductivity, such as heat exchangers, solar panels, or electrical wires. In conclusion, the benefits of using aluminum sheets include their lightweight nature, corrosion resistance, high strength-to-weight ratio, malleability, sustainability, and excellent thermal and electrical conductivity. These advantages make aluminum sheets a popular choice in various industries, contributing to improved performance, cost-effectiveness, and environmental sustainability.

Send your message to us

Sheets of Aluminum Diamond Plate with Better Discount Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords