Aluminum Dimond Plate

Aluminum Dimond Plate Related Searches

Aluminum Dimple Plate Aluminum Metal Plate Aluminum Round Plate Aluminum Wall Plate Aluminum Diamond Plate Panels Aluminum Diffuser Plate White Aluminum Diamond Plate Aluminum Diamond Deck Plate Aluminum Black Diamond Plate Aluminum Armor Plate Polished Aluminum Diamond Plate Aluminum Floor Plate Aluminum Profile Plate Aluminum Mold Plate Aluminum Mounting Plate Aluminum Diamond Plate Roll Aluminum Grill Plate Anodized Aluminum Diamond Plate Aluminum Sheet Diamond Plate Buy Aluminum Diamond Plate Bending Aluminum Diamond Plate Aluminum Paper Plate Aluminum Flat Plate Decorative Aluminum Plate Aluminum Cooking Plate Aluminum Hot Plate Aluminum Diamond Plate Strips Aluminum Base Plate Aluminum Triangle Plate Aluminum Cake PlateAluminum Dimond Plate Supplier & Manufacturer from China

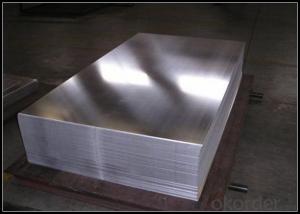

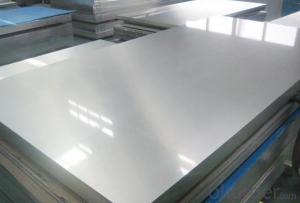

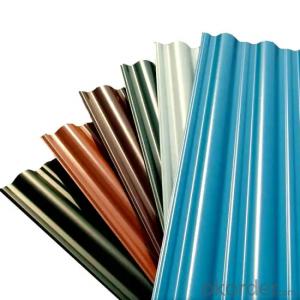

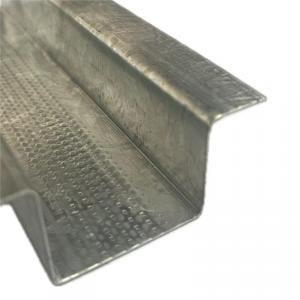

Aluminum Diamond Plate, also known as aluminum checker plate or aluminum tread plate, is a type of aluminum sheet material with a raised diamond pattern on one side. This pattern provides excellent slip resistance and durability, making it ideal for various applications where safety and longevity are paramount.Aluminum Diamond Plate is widely used in a variety of industries and settings, including construction, transportation, and manufacturing. It is commonly found in stair treads, flooring, ramps, walkways, and platforms, where slip resistance is crucial for safety. Additionally, it is used for truck beds, trailers, and other vehicles to prevent cargo from shifting during transit. The product's lightweight and corrosion-resistant properties make it a popular choice for both indoor and outdoor applications.

Okorder.com is a leading wholesale supplier of Aluminum Diamond Plate, offering a vast inventory of this product to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Aluminum Diamond Plate they provide meets the highest standards of performance and reliability.

Hot Products