Bright Polish Aluminum Tread Plate with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Bright Polish Aluminum Tread Plate Description:

Aluminum alloys 1xxx series, 2xxx series, 3xxx series, 5xxx series, 6xxx series and 8xxx series. They are available in various sizes with thicknesses from 0.1mm to 500mm, widths from 10mm to 3, 000mm andlengths below 12m. 1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment

2.Main Features of Bright Polish Aluminum Tread Plate :

Low density, light in weight

Anti-corrosion

Strong

Malleable

Naturally good looking

Recyclable

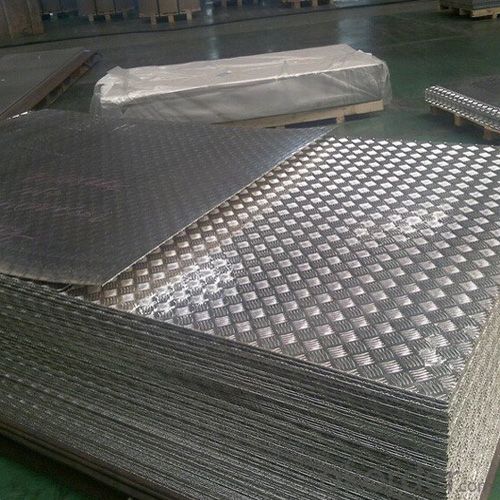

3.Bright Polish Aluminum Tread Plate Images:

4. Bright Polish Aluminum Tread Plate Specification:

Embossing Aluminum Tread Sheet | |

Alloy | 1100,1060, 3003, 5005 5052 |

Temper | H14,H18,H24,H32 |

Thickness (mm) | 1.5mm to 6mm |

Width (mm) | Up to 1500mm |

Length (mm) | Up to 6000mm |

Standard | EN standard ASTM standard |

MOQ | 5ton |

Application | 1)Decorated inside and outside the car /building frame, windows, doors, ceiling, decorating panel and curtain wall 2)Household appliances: refrigerators, microwave ovens, audio equipment, etc. |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum sheet be used for electrical grounding applications?

- Indeed, aluminum sheet finds utility in electrical grounding applications. It possesses remarkable conductive properties, rendering it apt for employment in grounding systems. Its low resistance and exceptional electrical conductivity make it a common choice in diverse electrical applications. With the capability to proficiently transport electrical current and securely disperse it into the ground, aluminum sheet guarantees the safeguarding of electrical systems and averts potential electrical dangers. Moreover, the lightweight and corrosion-resistant attributes of aluminum establish it as a favored option for grounding applications across numerous industries, encompassing construction, automotive, and aerospace.

- Q: Is it possible to incorporate windows made from recycled materials into a construction project?

- <p>Yes, you can use windows made from recycled materials in your project. There are eco-friendly windows available that are manufactured using recycled glass or other sustainable materials. These windows can offer similar performance to traditional ones while reducing the environmental impact of your construction. It's important to check the quality and certifications of the recycled windows to ensure they meet your project's requirements.</p>

- Q: What is the electrical resistivity of aluminum sheets?

- The electrical resistivity of aluminum sheets is approximately 2.65 × 10^-8 ohm·meter.

- Q: Are aluminum sheets suitable for insulation cladding?

- Aluminum sheets are a suitable option for insulation cladding. This material is highly versatile and durable, commonly used in construction for multiple purposes, including insulation cladding. The thermal properties of aluminum sheets are excellent, effectively preventing heat transfer. Additionally, their low thermal conductivity ensures improved energy efficiency by minimizing heat transfer between the building's interior and exterior. Moreover, aluminum is lightweight and easy to handle, making it convenient for installation purposes. It is also resistant to corrosion, allowing it to withstand various weather conditions and remain a long-lasting choice. Furthermore, aluminum sheets are available in different thicknesses, providing customization options based on specific insulation requirements. Not only do aluminum sheets possess functional benefits, but they also enhance the overall appearance of the building. With their sleek and modern look, these sheets can be easily painted or coated in different colors to match the desired aesthetic design. In conclusion, aluminum sheets are an excellent choice for insulation cladding due to their thermal properties, durability, ease of installation, and aesthetic appeal.

- Q: how to avoid oxidation of aluminum sheet after wire drawing?

- leave it alone after wire drawing!aluminum sheet will formulate a layer of dense oxide film. So you don't need to worry about it! Don't often polish the aluminum wire, or they will be more and more slimsy, the oxide film is used for avoiding reoxidation.

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum has excellent thermal conductivity and is lightweight, making it a suitable material for transferring heat efficiently in heat exchangers. Its corrosion resistance and durability also make it a popular choice in various heat exchange applications.

- Q: I constructed a small hho generator for experimental purposes. I needed to add a cooling condenser to the unit because of a overheating problem. I was using a old heater core from a vehicle, soldered some joints to make some connections. the solution seemed to have eaten the solder I used, which was normal lead free solder used in water pipes. I was going to invest into a trans cooler core which is made of aluminum, but I need to know if the solution will eat up the aluminum. I also thought about using a condenser core from a broken window a/c, which is made of copper tubing. any advise would be very help full

- Yes it will, especially for the aluminum. Since sodium hydroxide is strongly alkaline in an aqueous solution, it can corrode metals just like acids can. You will have to use synthetic pipes instead of metal ones that are resistant to caustic solutions.

- Q: Aluminum plate 90 degree bending, why cracking?

- Should be the aluminum sheet material and status is wrong, I wonder what brand aluminum plate?.Use 1060 Aluminum plate, condition: soft, 90 degree bending, won't crack

- Q: Are 101 aluminum sheets suitable for cryo-treating applications?

- Indeed, cryo-treating applications can benefit from the utilization of 101 aluminum sheets. Cryo-treating encompasses the practice of exposing materials to extremely low temperatures to enhance their strength, durability, and resistance to wear. 101 aluminum, being a commercially pure alloy, boasts exceptional corrosion resistance and favorable mechanical properties. It can endure cryogenic temperatures without experiencing considerable strength degradation or any adverse consequences. As a result, the application of 101 aluminum sheets in cryo-treating endeavors can effectively yield desired advantages and augment performance.

- Q: What specific tools or equipment are required when working with aluminum sheets?

- <p>When working with aluminum sheets, you'll need a few special tools and equipment. These include sheet metal shears for cutting, a metal file for smoothing edges, a metal straight edge for measuring and marking, and a vise for holding the sheet securely. For bending, a sheet metal brake is essential. Safety gear such as gloves and goggles are also crucial to protect against sharp edges and debris. Additionally, a T-square and a marker are needed for precise measurements and markings.</p>

Send your message to us

Bright Polish Aluminum Tread Plate with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords