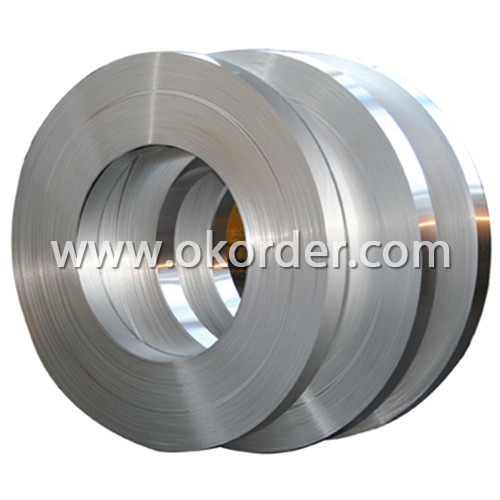

High Quality Aluminum Diamond Plate Strips AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of High Quality Aluminum Strips AA3003

Alloy Number | AA3003 |

Temper | Temper H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness | 0.10-500mm |

Diameter | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of High Quality Aluminum Strips AA3003

Aluminum strips are widely used for PS printed materials substrate, building decoration materials, stamping products, building mirror materials, nameplate, insulation materials, aluminum plastic composite material, capacitor strip, transformer strip, welding parts, heat exchanger, clock surface and disk, kitchen utensils, reflecting apparatus etc.

3. Packaging & Delivery of High Quality Aluminum Strips AA3003

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of High Quality Aluminum Strips AA3003

Rolling--Annealing--Slitting—Sawing, Cut-To-Length, Shearing

- Q: Is it possible to utilize aluminum strips for constructing outdoor decking or railings?

- <p>Yes, aluminum strips can be used for outdoor decking or railings. They are known for their corrosion resistance, low maintenance, and durability, making them suitable for outdoor applications. Aluminum is lightweight, strong, and can withstand various weather conditions without rusting. However, it's essential to ensure that the aluminum is of high quality and properly treated to maintain its performance over time. Additionally, it's crucial to follow proper installation practices to ensure safety and longevity.</p>

- Q: Explain the distinctions between aluminum foil and aluminum strips in a few sentences.

- <p>Aluminum foil and aluminum strips are both made from aluminum but differ in thickness and application. Aluminum foil is very thin, typically used for food packaging, cooking, and insulation due to its light weight and flexibility. It is also reflective, which makes it useful for cooking and baking. Aluminum strips, on the other hand, are thicker and more rigid, often used in construction, manufacturing, and automotive industries for structural support, heat exchangers, and electrical conductivity. They are not as flexible as foil and are not typically used for food-related applications.</p>

- Q: What are the potential health risks related to the use of aluminum foil?

- <p>While aluminum foil is widely used in cooking and food storage, there is limited evidence to suggest significant health risks. Some studies have linked aluminum exposure to neurological conditions like Alzheimer's, but the connection is not conclusive. The body does not absorb significant amounts of aluminum from foil, especially when used properly. However, it's important to avoid wrapping acidic or highly acidic foods in aluminum foil, as this could potentially lead to increased aluminum leaching. Overall, using aluminum foil in moderation and following proper food handling practices can minimize any potential risks.</p>

- Q: Is it possible to use aluminum strips as materials for roofing membranes?

- <p>Yes, aluminum strips can be used for roofing membranes. They are known for their durability, corrosion resistance, and lightweight properties, making them suitable for various roofing applications. Aluminum strips can be used in the form of standing seam metal roofs, which are popular for their sleek appearance and strength. They are also low maintenance and can be recycled, contributing to their environmental sustainability. However, it's important to ensure proper installation and sealing to prevent leaks and maintain the integrity of the roof.</p>

- Q: How does the excavator aluminum belt turn in place?

- This is how it works1. Support the front half of the track with the bucket, so that half or more of the track is out of the ground2, turn the operating lever in the opposite direction of the desired turn, and then turn the track

- Q: Is it possible to utilize aluminum strips as a material for insulating interior walls?

- <p>Aluminum strips are not typically used for interior wall insulation. Insulation materials are designed to provide thermal resistance, and aluminum is a good conductor of heat, which makes it unsuitable for insulation purposes. Common insulation materials include fiberglass, mineral wool, and polyurethane foam, which are effective at reducing heat transfer. Aluminum strips might be used in construction for other purposes, such as reinforcement or as a vapor barrier, but not for insulation.</p>

- Q: What kind of aluminum strip is most suitable for use as exterior trim, considering factors like durability and weather resistance?

- <p>The best type of aluminum strip for exterior trim is typically one made from high-quality aluminum alloy, such as 6063-T5 or 6061-T6. These alloys offer excellent strength, durability, and resistance to corrosion. They are also lightweight and can withstand various weather conditions without rusting or fading. Additionally, these aluminum strips often come with a protective coating or anodized finish, which enhances their resistance to UV rays, scratches, and other environmental factors. It's important to choose a strip that has been specifically designed for exterior use to ensure long-lasting performance.</p>

- Q: This question asks for an overview of the steps involved in the manufacturing of aluminum components used in vehicles.

- <p>The production process of automotive aluminum parts typically involves several key steps: material selection, design, casting or forging, machining, heat treatment, surface treatment, and quality control. Aluminum is chosen for its lightweight and high strength properties. The design phase involves creating detailed plans for the part. Casting or forging shapes the aluminum into rough forms. Machining refines these forms to precise specifications. Heat treatment enhances strength and durability. Surface treatments protect against corrosion and wear. Finally, quality control ensures each part meets industry standards before it is used in vehicles.</p>

- Q: What types of aluminum strips are more appropriate for commercial use?

- <p>Yes, there are specific types of aluminum strips that are more suitable for commercial applications. These include 1100 series aluminum strips, known for their high purity and excellent formability, making them ideal for general commercial purposes. 3003 series aluminum strips are also popular due to their enhanced corrosion resistance and formability, suitable for applications requiring moderate strength and good workability. Additionally, 5052 series aluminum strips offer good corrosion resistance and weldability, making them suitable for applications in the marine and transportation industries. The choice of aluminum strip depends on the specific requirements of the commercial application, such as strength, corrosion resistance, and formability.</p>

- Q: Is it possible to use aluminum strips for the exterior walls of a building?

- <p>Yes, aluminum strips can be used for exterior walls. They are lightweight, durable, and resistant to corrosion, making them suitable for cladding and facades. Aluminum strips can also be coated with various finishes to enhance their appearance and protect against weathering. They are commonly used in modern architecture for both aesthetic and functional purposes, offering a sleek and contemporary look while providing insulation and weather protection.</p>

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Aluminum Diamond Plate Strips AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords