5083 Cast Aluminum Plate

5083 Cast Aluminum Plate Related Searches

5083 0 Aluminum Plate 5083 Aluminum Armor Plate 5083 H32 Aluminum Plate 5083-H32 Aluminum Plate 5083 Aluminum Plate Supplier 5083 H116 Aluminum Plate 5083 H321 Aluminum Plate 5083-H321 Aluminum Plate 5083-H116 Aluminum Plate 5086 Aluminum Plate 5083 Aluminum Plate Prices 5086 H32 Aluminum Plate 5000 Series Cast Aluminum Plate Aluminum Cast Plate 5052 Aluminum Plate 5454 Aluminum Plate 5005 Aluminum Plate 5086 H116 Aluminum Plate 5052 0 Aluminum Plate 5086-H116 Aluminum Plate 5754 Aluminum Plate 5086 Aluminum Plate Suppliers 5086 Aluminum Plate Prices 5052 H32 Aluminum Plate 5052-H32 Aluminum Plate 5 8 Aluminum Plate 1/4 5052 Aluminum Plate 7085 Aluminum Plate 5mm Aluminum Plate 0.5 Aluminum Plate5083 Cast Aluminum Plate Supplier & Manufacturer from China

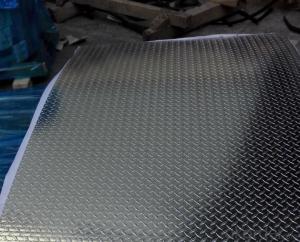

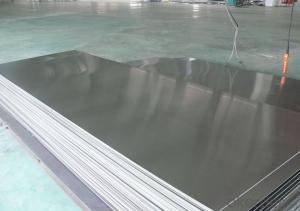

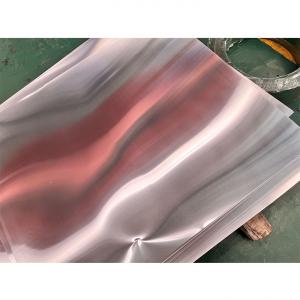

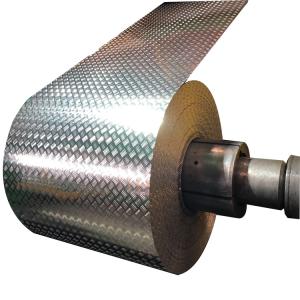

5083 Cast Aluminum Plate is a type of aluminum alloy known for its excellent corrosion resistance, weldability, and formability. This makes it a popular choice for a wide range of applications across various industries. The product is widely used in the manufacturing of marine components, automotive parts, and structural components due to its high strength-to-weight ratio and superior mechanical properties. Its versatility allows it to be utilized in both lightweight and heavy-duty applications, making it a valuable material for engineers and designers alike. Okorder.com is a leading wholesale supplier of 5083 Cast Aluminum Plate, offering customers a vast inventory of this high-quality material. With a commitment to providing top-notch products and services, Okorder.com ensures that customers receive the best possible 5083 Cast Aluminum Plate for their specific needs and requirements.Hot Products