Metal Aluminum Sheets - 5005 5052 5083 5754 Aluminum Tread Plate with Wide Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Production Introduction

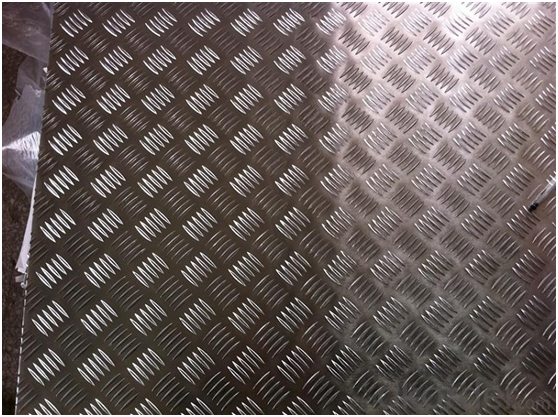

1. Commodity: Factory manufacture low price high quality aluminum dimond plate sheets

2. Alloy No.: 050 1060 1100 3003 3004 3104 3005 3105 5005 5052 8011

3. Size: Thickness: 0.15-5.00mm(Tolorance±0.02mm)

Width:200-1600mm(Tolorance±1mm)

Length: 500-1500mm(Tolorance±1mm)

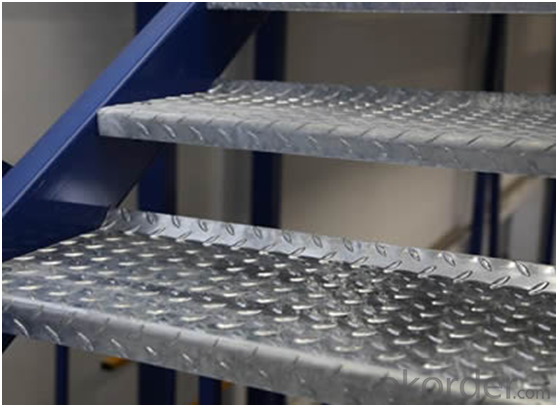

4. Application:

1) air plane, refrigerators ,audio equipment

2) building materials: ceilings, walls

3) telephones, digital cameras

4) plastic composite board, aluminum and plastic pipe

5.Month Capacity: 5000MT/Month

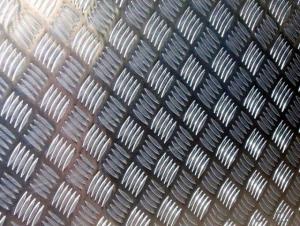

6.Pattern: 2 bars, 3 bars, 5 bars, diamond bar

l Packaging & Delivery

Packaging detail: First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation, wooden pallets

Delivery detail: Within 25days

l CNBM Images

l Product Images and Application

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What is the bending radius for aluminum sheets?

- The bending radius for aluminum sheets varies depending on the thickness and grade of the aluminum. Generally, for thin aluminum sheets, the bending radius can be around 1.5 times the thickness of the sheet. However, for thicker sheets, the bending radius may need to be larger to avoid cracking or deformation. It is recommended to refer to specific bending charts or consult with a metal fabrication expert for precise bending radius guidelines for different aluminum sheets.

- Q: When zinc dust and sulfur dust are combined in certain proportional ratios and ignited, a violent exothermic reaction occurs. Because the reaction only depends on two components; zinc and sulfur, but not oxygen, the reaction has all of the components that it needs within the mixture. The same is also true for a mixture of magnesium and sulfur.However, the same reaction does not occur with iron and sulfur. Instead, the mixture reacts slowly over a period of a few minutes rather than flashing to smoke in less than a second. Now for my questions:1: If aluminum and sulfur were combined in the same proportional ratios as the zinc and the magnesium mixtures were, would the reaction be as fast as the zinc and the magnesium mixtures? Why or why not?2: What properties of the different metals used in these mixtures makes them behave so differently?

- the forged iron crucible will honestly be dragging the warmth away,so attempt to discover a ceramic crucible---you will possibly have the potential to discover them at any rings furnish domicile.you will additionally so discover commercially arranged fluxes for melting,if no longer Borax powder is a fluxing agent I generally use.With the small quantity of meral you're wishing to soften,i think of your MAPP torch ought to artwork,be confident to change the flame to a lowering flame to steer clear of gassing the metallic.the availability domicile RIOGRANDE has an entire inventory of something you are able to require besides as some preprepared alloys which you will choose to objective.

- Q: This question asks about the various color options available for aluminum sheets.

- <p>Aluminum sheets are available in a wide range of colors to suit various applications and aesthetic preferences. Common colors include silver (anodized), white, black, and clear (natural). Beyond these, there are also options for colors like red, blue, green, and yellow. Some manufacturers offer custom color matching services for specific projects. Additionally, aluminum sheets can be coated with various finishes such as matte, gloss, or textured, further expanding the color and appearance options. It's important to check with specific suppliers for their available color range as it can vary.</p>

- Q: This question asks for the various types of surface treatments or coatings that can be applied to aluminum profiles to enhance their properties or appearance.

- <p>Aluminum profiles can be coated with several types of finishes to improve their aesthetic appeal, durability, and corrosion resistance. The common types include: 1) Anodizing, which creates a protective oxide layer on the aluminum surface; 2) Powder coating, where a dry powder is electrostatically applied and then cured under heat; 3) Electrophoretic coating, a method where charged particles adhere to the aluminum and then harden; 4) PVDF (Polyvinylidene Fluoride) coating, known for its excellent weather resistance and durability; 5) Thermal spraying, where a coating material is melted and sprayed onto the aluminum surface; and 6) Painting, which can be done through various methods such as airless spray or dip coating. Each type of coating serves different purposes and has its own set of advantages and applications.</p>

- Q: What are the different bending methods for aluminum sheets?

- Aluminum sheets can be bent using different methods, each with its own advantages and limitations. Various bending techniques for aluminum sheets include: 1. Air Bending: By utilizing a punch and die, a bend is formed in the aluminum sheet without direct contact. Compressed air is employed to exert force on the sheet, resulting in the desired bend. Air bending is a versatile method that allows for a range of bend angles and radii. 2. Bottom Bending: This method involves clamping the aluminum sheet between a V-shaped die and a flat die. A punch is then used to press the sheet into the V-shaped die, creating the desired bend. Bottom bending is suitable for achieving sharp bends with small radii. 3. Coining: Precise and crisp bends are formed by applying high pressure to the aluminum sheet between a punch and a die. Coined bends exhibit minimal springback. However, this method requires specialized equipment and is typically utilized for high-volume production. 4. Roll Bending: By passing the aluminum sheet between a set of rollers, it is gradually bent into the desired shape. Roll bending is commonly employed for creating cylindrical or conical shapes. This technique can achieve large radii and is suitable for thicker aluminum sheets. 5. Press Brake Bending: This commonly used method employs a hydraulic or mechanical press brake to create bends in aluminum sheets. The sheet is clamped between a punch and a die, and the press brake applies force to create the bend. Press brake bending offers flexibility in terms of bend angles and radii. It is important to consider various factors such as the desired bend angle, radius, material thickness, and specific application requirements when selecting a bending method.

- Q: How do you achieve a mirror-like finish on aluminum sheets?

- Achieving a mirror-like finish on aluminum sheets involves a series of steps to remove any imperfections and create a smooth, reflective surface. Here are the key processes involved: 1. Surface preparation: Start by thoroughly cleaning the aluminum sheet to remove any dirt, grease, or other contaminants using a mild detergent and water. Rinse and dry the surface completely. 2. Sanding: Use progressively finer grits of sandpaper or abrasive pads to remove any scratches, oxidation, or roughness on the aluminum surface. Begin with a coarser grit (around 120-180) and gradually move to finer grits (up to 1000 or higher) to achieve a smoother finish. Sanding should be done in a consistent direction to avoid creating visible scratches. 3. Polishing compounds: Apply a polishing compound or metal polish designed specifically for aluminum surfaces. Use a soft cloth or a buffing wheel to apply the polish and work it into the surface. Apply gentle pressure and move in circular motions to evenly distribute the polish. Repeat this step until the desired level of shine is achieved. 4. Buffing: Use a buffing wheel, preferably made of felt or cotton, to further enhance the shine. Apply a small amount of a high-quality polishing compound to the wheel and carefully buff the aluminum sheet in a consistent manner. Again, use circular motions and maintain a steady, even pressure. 5. Final polishing: To achieve a mirror-like finish, use a specialized aluminum polish or a metal finishing compound. Apply a small amount onto a clean cloth and gently rub the surface in circular motions. This final step helps remove any fine scratches or imperfections, adding a brilliant shine to the aluminum sheet. Remember to clean the aluminum sheet thoroughly after each step to remove any residue or excess polish. Additionally, always follow the manufacturer's instructions when using specific polishing compounds or tools, as they may have specific guidelines for optimal results. By following these steps carefully and patiently, you can achieve a mirror-like finish on aluminum sheets, transforming them into highly reflective surfaces that are both visually appealing and functional.

- Q: What are the fire-resistant properties of aluminum sheets?

- Aluminum sheets offer impressive fire-resistant qualities, making them an ideal choice for different applications that prioritize fire safety. The primary explanation for their fire resistance lies in the natural formation of a unique oxide layer on the aluminum's surface when exposed to oxygen. This layer acts as a protective barrier, preventing further oxidation and reducing the likelihood of combustion. Not only is the oxide layer on aluminum sheets highly stable, but it also boasts a high melting point. Consequently, it can endure high temperatures without melting or catching fire, rendering it flame-resistant. Additionally, the oxide layer acts as an effective thermal insulator, slowing down heat transfer and impeding the spread of fire. Another benefit of aluminum sheets is their low flammability. Aluminum is a non-combustible material, meaning it does not burn or support combustion. This characteristic proves especially advantageous in situations where fire containment and prevention are critical. Furthermore, aluminum sheets possess exceptional heat dissipation capabilities. They swiftly disperse heat away from the source, minimizing the risk of overheating and potential fire hazards. This makes them suitable for various heat-intensive applications, including electrical enclosures, automotive parts, and industrial machinery. In conclusion, aluminum sheets demonstrate remarkable fire-resistant qualities due to the protective oxide layer, non-combustible nature, and efficient heat dissipation. These attributes make them highly sought after for applications that prioritize fire safety, offering reassurance and safeguarding against potential fire incidents.

- Q: Can aluminum sheet be used for cookware?

- Indeed, cookware can indeed employ aluminum sheets. Aluminum, being renowned for its superb heat conductivity, facilitates even heat dispersion and rapid heating. It possesses the attributes of being lightweight, long-lasting, and impervious to rust and corrosion. Moreover, aluminum cookware is reasonably priced and comparatively effortless to maintain. Nevertheless, pure aluminum proves to be a malleable metal, thus necessitating its amalgamation with other substances such as stainless steel or nonstick coatings to fortify its endurance and nonstick qualities.

- Q: Are aluminum sheets suitable for chemical processing equipment?

- Yes, aluminum sheets are suitable for chemical processing equipment under certain conditions. Aluminum has good resistance to a wide range of chemicals, including many acids and alkalis. It is particularly resistant to corrosion in acidic environments such as hydrochloric acid and sulfuric acid, as well as alkaline solutions like sodium hydroxide. However, it is important to note that aluminum is not suitable for all chemical processes. It is not recommended for applications involving strong oxidizing agents, such as nitric acid or chromic acid, as these can rapidly corrode aluminum. Additionally, aluminum is not compatible with certain organic solvents and can react with them, causing degradation or failure of the equipment. In some cases, aluminum can be used in chemical processing equipment by applying protective coatings or linings to enhance its resistance to specific chemicals. This can extend its durability and allow it to be used in a wider range of applications. Overall, while aluminum sheets can be suitable for chemical processing equipment in many instances, it is essential to carefully consider the specific chemicals and operating conditions involved to ensure compatibility and avoid any potential corrosion or failure issues.

- Q: Can aluminum sheet be used for automotive applications?

- Indeed, aluminum sheet finds its application in the automotive industry. Offering a combination of lightness and strength, aluminum serves as a highly advantageous material. Car bodies, hoods, doors, and various structural components are extensively manufactured using aluminum. The preference for aluminum sheets in these applications stems from their exceptional strength-to-weight ratio, resistance against corrosion, and durability. Moreover, aluminum exhibits ease in forming, enabling the attainment of intricate shapes and designs. The utilization of aluminum in automotive applications further contributes to enhanced fuel efficiency and reduced emissions due to its reduced weight. Ultimately, the manifold advantageous characteristics of aluminum sheets render them a suitable choice for automotive applications.

Send your message to us

Metal Aluminum Sheets - 5005 5052 5083 5754 Aluminum Tread Plate with Wide Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords