Marine Grade 3003 H14 Aluminum Coil with High Quality 5083 Aluminum Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Marine Grade Aluminum Plate 5083 Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Marine Grade Aluminum Plate 5083 :

Anodised aluminium sheet

Mirror finish aluminium sheet

Stucco aluminium sheet

Competitive Price

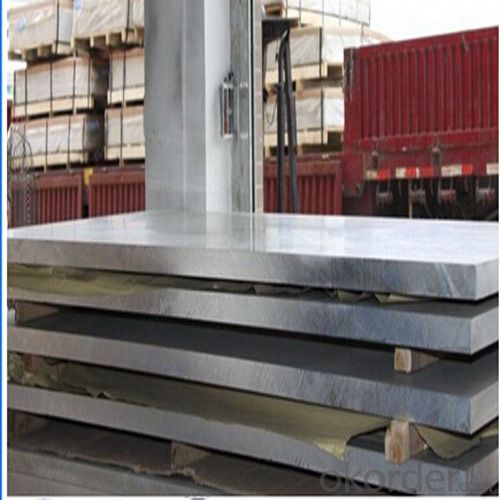

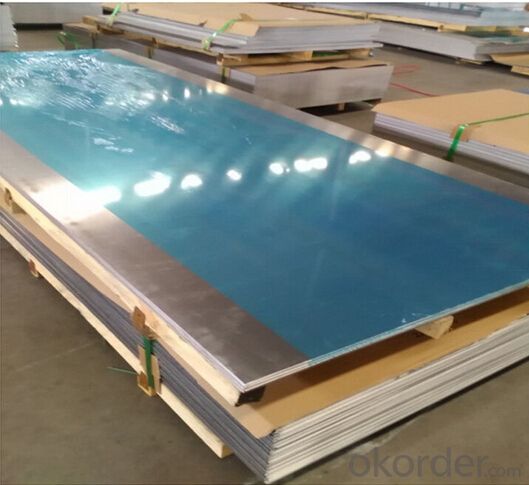

3. Marine Grade Aluminum Plate 5083 Images:

4. Marine Grade Aluminum Plate 5083 Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum coils be used in the production of aluminum composite windows?

- Yes, aluminum coils can be used in the production of aluminum composite windows. Aluminum coils are commonly used in the manufacturing process of aluminum composite windows. These coils are made from high-quality aluminum and are often used as the raw material that is then formed and shaped into the desired window frames and components. Aluminum coils offer several advantages in the production of aluminum composite windows, including their lightweight nature, durability, and resistance to corrosion. These qualities make aluminum coils a suitable choice for manufacturers looking to produce high-quality and long-lasting aluminum composite windows.

- Q: Can aluminum coils be used in high-pressure or high-temperature environments?

- Aluminum coils are not typically recommended for use in high-pressure or high-temperature environments. While aluminum is known for its high thermal conductivity and corrosion resistance, it has certain limitations when exposed to extreme conditions. In terms of high-pressure environments, aluminum coils may not possess the necessary strength and durability required to withstand the forces exerted by the pressurized system. Aluminum has a lower tensile strength compared to other metals like steel or titanium, which makes it more prone to deformation or failure under high pressure. Therefore, it is generally advised to use materials with higher strength and pressure ratings in such scenarios. Similarly, aluminum coils have a relatively low melting point compared to metals like steel or copper. The melting point of aluminum is around 660 degrees Celsius (1220 degrees Fahrenheit), which makes it susceptible to damage or failure in high-temperature environments. In applications where the temperature exceeds the melting point of aluminum, it is recommended to use materials with higher temperature resistance. However, it is worth mentioning that there are specialized alloys and coatings available that can enhance the high-temperature and high-pressure capabilities of aluminum. These modifications can improve its strength, heat resistance, and corrosion resistance, making it suitable for certain applications in extreme conditions. Nonetheless, the specific requirements and limitations of the intended environment should be carefully considered before deciding to use aluminum coils. Consulting with experts and considering alternative materials may be necessary to ensure the safety and efficiency of the system.

- Q: What is the thickness tolerance of aluminum coils?

- The thickness tolerance of aluminum coils can vary depending on the specific grade and manufacturing process. Generally, the standard thickness tolerance for aluminum coils is around +/- 0.005 inches (+/- 0.13 mm). However, it is important to note that this tolerance can be further refined or adjusted based on the customer's specific requirements and the capabilities of the manufacturer. Some specialized aluminum coil manufacturers may offer even tighter thickness tolerances, typically around +/- 0.002 inches (+/- 0.05 mm), to meet more precise or demanding applications. It is always recommended to consult with the manufacturer or supplier to ensure the desired thickness tolerance is met for a particular project or application.

- Q: This question asks for methods to take care of and preserve aluminum coils, ensuring their longevity and functionality.

- <p>To maintain aluminum coils, follow these steps: Keep them clean by wiping off any dust or debris. Store them in a dry environment to prevent corrosion. Avoid stacking heavy objects on top to prevent deformation. Regularly inspect for any signs of damage or wear. Use appropriate handling equipment to avoid scratches or dents. Apply a protective coating if exposed to harsh conditions. Ensure proper ventilation during storage to prevent condensation. By following these practices, you can prolong the life and maintain the quality of aluminum coils.</p>

- Q: What is the typical thermal expansion coefficient for aluminum coils?

- The typical thermal expansion coefficient for aluminum coils is around 23.1 x 10^-6 per degree Celsius (or 23.1 x 10^-6/°C). This coefficient represents the change in length of an aluminum coil per degree Celsius increase in temperature. It is important to note that this value may vary slightly depending on the specific alloy and composition of the aluminum coil.

- Q: Can aluminum coils be used in the production of solar panels?

- Aluminum coils are indeed suitable for the production of solar panels. Being a lightweight and durable material, aluminum brings numerous advantages to the manufacturing process. Its high conductivity and exceptional thermal properties enable efficient dissipation of heat. Furthermore, aluminum exhibits resistance to corrosion, a vital characteristic for solar panels as they encounter diverse weather conditions. Moreover, the cost-effectiveness of aluminum makes it a favored option in the solar industry. By employing aluminum coils in solar panel production, the performance, durability, and cost-effectiveness of these panels are greatly improved.

- Q: What are the potential safety hazards when using a soldering iron on copper or aluminum coils?

- <p>Using a soldering iron to solder copper or aluminum coils can pose safety risks. Copper and aluminum can react when joined, potentially leading to a galvanic corrosion. Additionally, the high heat from the soldering iron can cause the metal to expand or deform, especially if not handled properly. Always ensure proper ventilation to avoid inhaling fumes from the soldering process. Wear heat-resistant gloves and safety glasses to protect against burns and flying debris. Ensure the work area is clear of flammable materials to prevent fire hazards.</p>

- Q: Can aluminum coils be used in the production of fire-resistant structures?

- Indeed, the utilization of aluminum coils is possible for the fabrication of fire-resistant structures. Being inherently fire-resistant and possessing a remarkably high melting point, aluminum emerges as an excellent substance for structures that necessitate endurance against elevated temperatures. In the realm of construction, aluminum coils are frequently employed to fulfill fire-resistant requirements, including roofs, walls, and insulation. Moreover, the lightweight and durability of aluminum further facilitate the installation and maintenance of fire-resistant structures.

- Q: Can aluminum coils be custom-made to specific requirements?

- Yes, aluminum coils can be custom-made to specific requirements. Aluminum coils are versatile and can be tailored to meet a wide range of specifications and applications. Manufacturers can customize the dimensions, thickness, width, and length of the coil to accommodate specific requirements. Additionally, various surface finishes, such as embossed patterns or coatings, can be applied to enhance the appearance or improve functionality. Customization of aluminum coils allows for precise matching of specific needs in industries such as construction, transportation, aerospace, and many others.

- Q: What are the potential fire hazards associated with aluminum coils?

- The potential fire hazards associated with aluminum coils include overheating, electrical failures, and the risk of flammable materials coming into contact with the coils.

Send your message to us

Marine Grade 3003 H14 Aluminum Coil with High Quality 5083 Aluminum Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords