Aluminum Sheets in Oklahoma - Alloy 5083/5052/5754 Embossed Aluminium Plate/Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

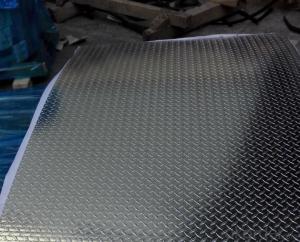

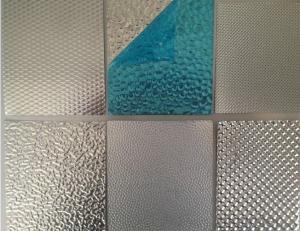

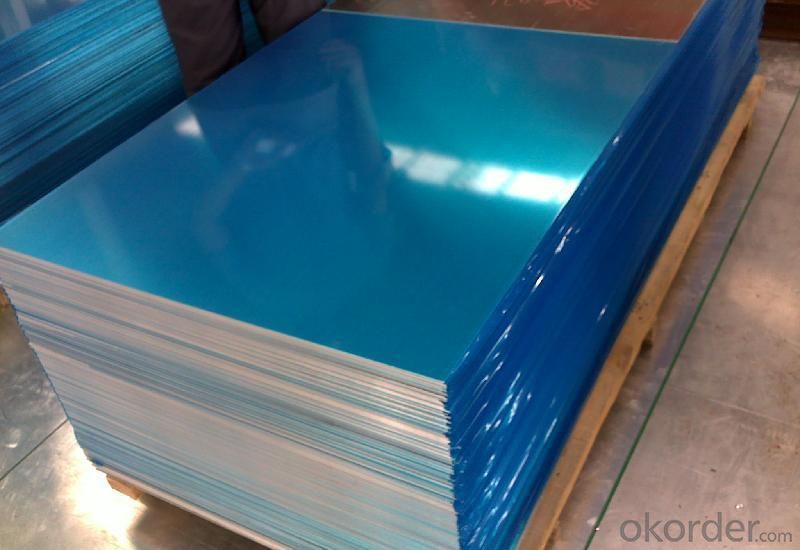

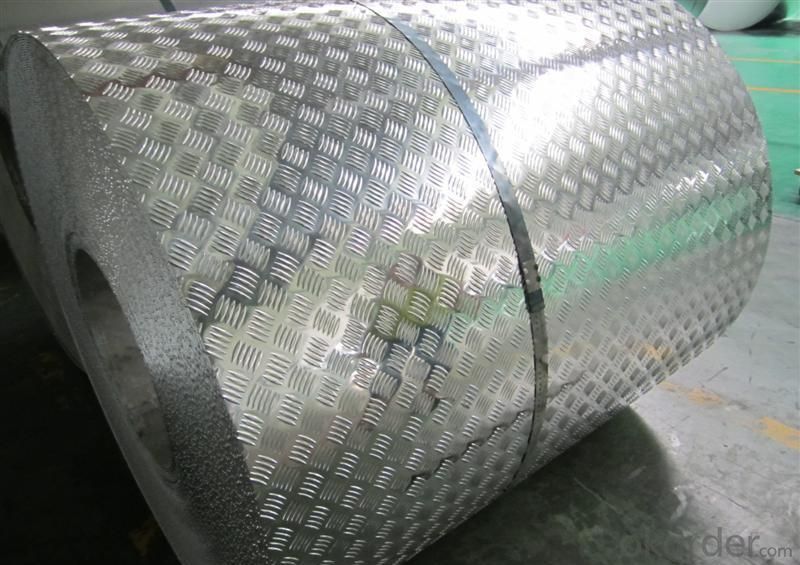

Description of Alloy 5083/5052/5754 Embossed Aluminium Plate/Sheet

Alloy | Temper | Specification(mm) | ||||

Thickness | Width | Length | Embossing Depth | Surface Treatment | ||

1050, 1060, 1100, 1070, 3003, 3105, etc. | O, H12, H14, H16, H18, H22, H24, H26, H32, etc. | 0.25~2.0 | ≤1250 | As per customer’s | 0.08~0.25 | Mill Finish, Bright Finish, Anodized, Color Coated |

Tolerance | ||||||

Thickness (base materials) | Thickness | Embossing Depth | Width | Length | Diagonal | |

0.25~0.5 | 0~0.05 | +/- 0.01 | +/-0.5 | +/- 1.0 | +/- 1.5 | |

> 0.5~2.0 | 0~0.10 | +/- 0.02 | +/-1.0 | +/- 1.5 | +/- 2 | |

We can produce as per customers’ special requirements. | ||||||

Chemical composition of Alloy 5083/5052/5754 Embossed Aluminium Plate/Sheet

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Other | Min Al/ % | ||

Single | Total | ||||||||||||

3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | - | 0.10 | - | - | 0.05 | 0.15 | Remain |

3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | 0.15 | - | 0.25 | - | - | 0.05 | 0.15 | Remain |

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: If one were to hit someone with a baseball bat, would it cause more pain to use a wooden bat or an aluminum one? Just wondering.

- I've been chased with an aluminum bat, but haven't ever been hit with either. I would say that the wooden bat would hurt more, because that's solid wood. An aluminum bat is hollow. But then yet, I've red articles where aluminum bats perform better for some kind of scientific reason that I didn't quite understand. So if an aluminum bat performs better on a baseball, it would be safe to assume that perhaps it would hurt more to be hit with an aluminum one. But either way, it's safe to say... I'd rather not be hit with either!

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of a building?

- <p>Yes, aluminum sheets can be used for exterior walls. They are lightweight, durable, and resistant to weathering and corrosion, making them suitable for facades. Aluminum sheets can be easily shaped and offer design flexibility. They also have good thermal properties and can be coated or finished in various ways to enhance their appearance and performance. However, they may not provide the same insulation as traditional materials, so additional insulation may be required.</p>

- Q: Does aluminum sheet require special handling during transportation?

- Transporting aluminum sheets requires special handling due to their lightweight nature and susceptibility to damage if mishandled. To prevent scratching, bending, or denting, it is necessary to take specific precautions. Packaging and securing the sheets in a manner that restricts movement and offers sufficient protection against impacts is crucial. Furthermore, it is important to transport aluminum sheets separately from heavy objects or materials to avoid potential damage caused by their weight. In conclusion, ensuring the safe transportation of aluminum sheets necessitates giving them special care and attention.

- Q: What is the maximum width available for aluminum sheets?

- The maximum width of aluminum sheets can differ depending on the manufacturer and specific specifications. Typically, aluminum sheets can be found in widths up to 72 inches or 1.83 meters. It should be emphasized that certain manufacturers may provide wider choices for specialized purposes. Furthermore, personalized dimensions can be acquired by placing specific orders, providing more freedom in selecting the desired width.

- Q: Can aluminum sheet be used in marine environments?

- Certainly, aluminum sheet finds utility in marine environments. The corrosion resistance exhibited by aluminum renders it a favored material for marine purposes. The formation of a safeguarding oxide layer on its exterior effectively curbs corrosion, even in the presence of saltwater. Moreover, aluminum's lightweight nature qualifies it as an optimal selection for marine applications where weight reduction is paramount. Given its robustness, strength, and corrosion resistance, aluminum sheet is extensively employed in boat hulls, decks, and various other marine constructions.

- Q: Can aluminum sheets be used for electronic enclosures?

- Yes, aluminum sheets can be used for electronic enclosures. Aluminum is a commonly used material for electronic enclosures due to its excellent properties. It is lightweight, corrosion-resistant, and provides good electromagnetic shielding. Aluminum sheets can be easily formed and fabricated into various shapes and sizes, making them suitable for housing electronic components. Furthermore, aluminum has good thermal conductivity, allowing for efficient heat dissipation from the enclosed electronics. Overall, aluminum sheets are a popular choice for electronic enclosures due to their durability, versatility, and electrical properties.

- Q: What oil does the aluminum plate stretch with?

- There are professional tensile oil, you can ask to pull the rice cooker liner manufacturers know, if not a lot of production, you can use peanut oil first try, the effect barely enough!

- Q: Are the aluminum sheets suitable for manufacturing heat exchanger tubes?

- Yes, aluminum sheets are suitable for manufacturing heat exchanger tubes. Aluminum has excellent thermal conductivity, corrosion resistance, and is lightweight, making it an ideal material for heat transfer applications.

- Q: Can aluminum sheets be used for decorative wall panels?

- Yes, aluminum sheets can be used for decorative wall panels. Aluminum is a versatile material that can be easily manipulated to create various designs and finishes. It is lightweight, durable, and offers a sleek and modern look, making it a popular choice for decorative wall applications.

Send your message to us

Aluminum Sheets in Oklahoma - Alloy 5083/5052/5754 Embossed Aluminium Plate/Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords