5083 Aluminum Coils Wholesale Direct Casting Aluminum Circle for Pot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

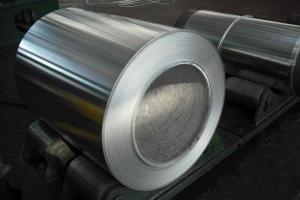

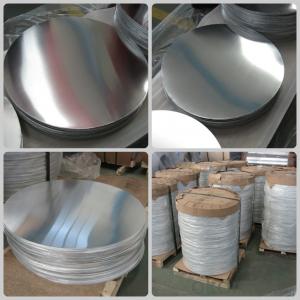

1. Structure of DC Aluminium in Coil Form for making Aluminium Circle Description

CC Aluminium in Coil Form for making Aluminium Circle is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Feature of DC Aluminium in Coil Form for making Aluminium Circle

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

3. Image of DC Aluminium in Coil Form for making Aluminium Circle

4. Specification of DC Aluminium in Coil Form for making Aluminium Circle

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

5. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4)What about payment term?

30% T/T in advance, balance against B/L COPY.

- Q: How much of a difference does it make? I recently bought a 700 SPS tactical in 308. It has the Houge pillar bedding stock. I love the tacky feeling rubber outside, but noticed that the fore end of the stock flexes a bit (enough to touch the free floating barrel.) I was wondering if the aluminum bedding block version of the same stock (or any other aluminum bedding stock) will be better? I know they cost more, and the experts claim they're great, but will an amateur shooter notice the difference? I like to target shoot, typically around 200 yards. BTW, I was also considering the Bell and Carlson medalist.

- Vote for the Aluminum yet somewhat might like a silver lined one bless by using a Catholic priest that emits holy water. That way in case they are additionally a vampire you nailed them.

- Q: Is it possible to use an aluminum coil as a paperweight for holding down papers?

- <p>Yes, you can use an aluminum coil as a paperweight. Aluminum is a lightweight and sturdy metal that can effectively hold down papers on a desk. Its weight and shape make it suitable for this purpose. However, ensure the coil is clean and smooth to avoid any damage to the papers or surfaces it comes into contact with. Additionally, consider the size and thickness of the coil to ensure it provides enough weight to keep your papers in place.</p>

- Q: Can aluminum coils be used in the production of aluminum facades?

- Yes, aluminum coils can be used in the production of aluminum facades. Aluminum coils are commonly used in the construction industry for various applications, including the production of facades. The coils are typically made from high-quality aluminum alloy, which offers excellent durability, corrosion resistance, and aesthetic appeal. The coils can be easily shaped, cut, and formed to create the desired design and size for the aluminum facades. Additionally, aluminum coils can be coated with different finishes, such as powder coating or anodizing, to provide further protection and enhance the appearance of the facades. Overall, aluminum coils are a versatile and reliable material for the production of aluminum facades, offering a wide range of design possibilities and long-lasting performance.

- Q: Can aluminum coils be used for roofing applications?

- Yes, aluminum coils can be used for roofing applications. Aluminum is a popular choice for roofing due to its lightweight nature, durability, and resistance to corrosion. It is commonly used for both residential and commercial roofing projects.

- Q: I'm doing a project on aluminum and this is the one thing i can't find. Also will it rust, tarnish or corrode?

- Aluminum is actually highly reactive. Under normal conditions, its outer layer quickly forms a coating of aluminum oxide which is extremely hard and well-attached. This prevents any further corrosion or oxidation. Molten aluminum will react explosively with water; this is a well-known danger in the aluminum casting industry. Very finely powdered aluminum is pyrophoric (self-igniting in air) and is used as a component in flash powder and some solid rocket fuels.

- Q: What are the common surface finishes for aluminum coils in the electrical industry?

- In the electrical industry, aluminum coils are commonly used for various applications such as transformers, motors, and electrical enclosures. These coils are often subjected to different surface finishing processes to enhance their performance and longevity. One of the most common surface finishes for aluminum coils in the electrical industry is anodizing. Anodizing involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. This layer not only provides excellent corrosion resistance but also improves the coil's durability and electrical insulation properties. Another popular surface finish is chemical conversion coating, also known as chromate conversion coating. This process involves treating the aluminum surface with a chemical solution to create a thin layer of protective coating. The coating not only provides corrosion resistance but also improves the adhesion of subsequent coatings or paints applied to the coil. Powder coating is another common surface finish used in the electrical industry for aluminum coils. It involves applying a dry powder onto the coil's surface and then curing it under heat to create a durable and attractive finish. Powder coating provides excellent resistance to chipping, scratching, and fading, making it ideal for applications where aesthetics and durability are important. In addition to these surface finishes, aluminum coils in the electrical industry may also undergo other treatments such as lacquering or painting. Lacquering involves applying a clear protective coating to the coil's surface, providing a glossy and protective finish. Painting, on the other hand, involves applying a colored coating to the surface for aesthetic purposes while also providing protection against corrosion. Overall, the choice of surface finish for aluminum coils in the electrical industry depends on the specific requirements of the application. Factors such as corrosion resistance, electrical insulation, durability, and aesthetics play a significant role in determining the most suitable surface finish for a given application.

- Q: wood aluminium windows?

- Vinyl looks MODERN and are in all the track homes. If you want you home to look cookie cutter choose the vinyl. If you have a nice home in an upscale neighborhood choose wood and any other other combo of wood and ?. If you are like the rest of us average shmos get the white vinyl

- Q: How are aluminum coils different from other types of metal coils?

- Aluminum coils differ from other types of metal coils in several ways. Firstly, aluminum is a lightweight metal, making aluminum coils much lighter compared to coils made from other metals such as steel or copper. This lightweight property of aluminum makes it a popular choice for various industries where weight is a critical factor, such as aerospace and automotive industries. Secondly, aluminum coils have excellent corrosion resistance. Unlike other metals, aluminum forms a protective oxide layer on its surface when exposed to air, preventing further corrosion. This resistance to corrosion makes aluminum coils suitable for applications in humid and corrosive environments, such as marine or coastal areas. Additionally, aluminum coils possess high thermal conductivity. This means that aluminum can efficiently conduct heat, making it an ideal material for heat transfer applications like HVAC systems, refrigeration units, and radiators. The high thermal conductivity of aluminum coils allows for more efficient cooling or heating processes. Furthermore, aluminum is highly malleable and ductile, which means it can be easily shaped and formed without losing its structural integrity. This malleability makes aluminum coils flexible and versatile, allowing them to be manufactured into various shapes and sizes to meet specific industry requirements. Lastly, aluminum is a highly sustainable and recyclable material. It can be recycled repeatedly without losing its quality or performance, making aluminum coils an environmentally friendly choice. This recyclability factor contributes to reducing the environmental impact and promoting a circular economy. In summary, aluminum coils stand out from other metal coils due to their lightweight, corrosion resistance, high thermal conductivity, malleability, and recyclability. These unique properties make aluminum coils a preferred choice for a wide range of applications across different industries.

- Q: What are the weight savings achieved by using aluminum coils?

- The weight savings achieved by using aluminum coils can vary depending on the specific application, but generally speaking, aluminum coils are significantly lighter than traditional materials such as steel. On average, aluminum coils can provide weight savings of around 50% or more compared to steel coils. This weight reduction is especially beneficial in industries like automotive, aerospace, and construction, where lighter materials can contribute to improved fuel efficiency, increased load capacity, and enhanced overall performance.

- Q: Which would you guys recommend to a 13 year-old? I used a wooden bat at my last game, and I got a double to the left field wall, I don't think i've done that good with an aluminum bat all year. Should I continue using the wooden one? What do you guys think?

- Wooden bats are cooler anyways. Sure, anybody can use an Aluminum bat, but how many kids your age are using Wooden bats? Besides, Aluminum bats are more dangerous.

Send your message to us

5083 Aluminum Coils Wholesale Direct Casting Aluminum Circle for Pot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords