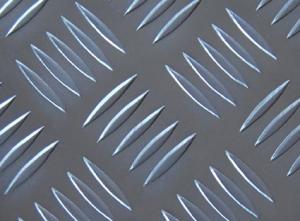

6063 Aluminum Coil Manufacture Five Bar Pattern 5052 4mm Aluminum Checkered Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

5052 4mm aluminum checkered plate

Alloy:1050 1060 1070 1100 3003 5052

Partterns:diamond ,Two,three,Five Bar

Temper:O-H112

Thickness:0.3-8 mm

packing:wooden pallet,wooden case or as customer request

Application of Aluminum Durbar floor plate : Indoor and outdoor decoration, flooring, stairs, construction

Payment: TT or LC .

Company Information

Through the years, we have built many modern production lines, including one 1+2 hot rolling production line, six 2,450, 2,050, 1,650 and 1,450mm cold rolling lines, two 1,650mm foil rolling production lines, two 1,850mm continuous rolling production lines and one roll coating production line. Besides, we also bring in 8 x 20 annealing furnaces, tension leveled machines, tension pre-stretch machines, cutting machines, cleaning equipment, testing machines and packing equipment from at home and abroad to be able to complete various clients' requirements

FAQ

Q: Which country CNBM export to ?

A: Export to over 30 countries, especial Brazil, Chile, Iraq, Australia.etc

Q: What can we expect from CNBM?

A: Yes, as customer request

Q: Can I have some samples?

A: Of course, samples are free (1-3 pcs) or 2-3 kg

Q: When can we get samples and goods?

A: Samples will be sent immediately if have stock, make new will take 2-3days.

Goods will be shipped within 20 days after order confirmed

Packaging & Delivery

| Packaging Details: | Wooden Pallet, Wooden Case, As Customzed, etc. |

| Delivery Detail: | 20~25DAYS |

- Q: Can aluminum coils be used in the production of aluminum sandwich panels?

- Aluminum sandwich panels can indeed utilize aluminum coils. Typically, these coils serve as the outer skins or facings of the panels. To enhance their durability, resistance to corrosion, and aesthetic appeal, the coils undergo initial processing and coating. This process ensures that they possess the desired qualities. Subsequently, they are bonded with a core material, such as polyethylene or mineral wool, to create a sandwich panel structure that is both lightweight and rigid. The inclusion of aluminum coils provides the panels with exceptional mechanical properties, including a high strength-to-weight ratio, flexibility, and thermal conductivity. Moreover, the use of aluminum coils enables convenient customization as they can be formed, shaped, and painted to meet specific design and specification requirements.

- Q: Which is better composite or aluminum, and what are some main differences between the two?

- I used the Easton Stealth Composite a few years back and it had the most pop of any bat I have ever used. I never seemed to miss the sweet spot, and I don't think it was necessarily because of MY skill.

- Q: What is the lifespan of aluminum coils?

- The lifespan of aluminum coils can vary depending on various factors such as the quality of the aluminum, the manufacturing process, the environmental conditions they are exposed to, and the maintenance provided. However, on average, aluminum coils can last anywhere from 15 to 30 years. With proper care and regular maintenance, including cleaning and inspection, aluminum coils can potentially have an extended lifespan. It is important to note that regular maintenance and servicing by professionals can help identify any issues early on, allowing for timely repairs or replacements, ultimately prolonging the lifespan of aluminum coils.

- Q: What is the weight of an average aluminum coil?

- The weight of an average aluminum coil can vary depending on its dimensions and thickness. However, a typical aluminum coil can weigh anywhere between 1,000 to 10,000 pounds (450 to 4,500 kilograms).

- Q: Can aluminum coils be painted or coated for aesthetic purposes?

- Yes, aluminum coils can be painted or coated for aesthetic purposes. This process involves applying a suitable paint or coating to the surface of the coils to enhance their appearance and provide protection against corrosion or other environmental factors.

- Q: What is the bending radius for aluminum coils?

- The bending radius for aluminum coils can vary depending on the thickness and alloy of the aluminum. However, as a general guideline, the minimum bending radius for aluminum coils is typically around 1.5 times the thickness of the coil.

- Q: What are the rules and guidelines that govern the transport of aluminum coils?

- <p>Yes, there are specific regulations for the transportation of aluminum coils. These include adhering to weight limits, ensuring proper packaging to prevent damage, and following guidelines for secure loading and unloading. Compliance with hazardous materials regulations is also crucial if the coils are being transported internationally. It's important to check with the specific transportation authority or consult the International Air Transport Association (IATA) and International Maritime Dangerous Goods (IMDG) codes for detailed guidelines.</p>

- Q: What are the standard sizes of aluminum coils?

- The specific industry and application can cause variations in the standard sizes of aluminum coils. Nevertheless, there are several widely used common standard sizes. For general industrial applications, the width of aluminum coils usually falls within the range of 36 to 72 inches. The thickness of these coils typically varies from 0.018 to 0.125 inches. The length of the coils may differ, but it is commonly around 1,000 feet or more. In the construction industry, the standard sizes of aluminum coils can differ. The width can vary between 24 and 48 inches, while the thickness can range from 0.019 to 0.032 inches. The length of these coils can also vary depending on the specific project requirements. It is important to note that these sizes serve as general guidelines and can vary based on the specific manufacturer, industry requirements, and customer preferences. It is always advisable to consult the manufacturer or supplier to determine the exact standard sizes available for aluminum coils in your specific industry.

- Q: Can aluminum coils be used in electrical wiring applications?

- Yes, aluminum coils can be used in electrical wiring applications. Aluminum has been used as a conductor in electrical wiring for many years, especially in residential and commercial buildings. It is a lightweight and cost-effective alternative to copper. Aluminum coils are commonly used in applications such as power distribution, transformers, and motors. However, it is important to note that aluminum has different electrical and mechanical properties compared to copper, so proper installation techniques and connectors specifically designed for aluminum wiring should be used to ensure safety and efficiency.

- Q: What are some common defects in aluminum coils?

- Some common defects in aluminum coils include: 1. Surface defects: These can include scratches, pits, dents, or waviness on the surface of the coil. These defects can occur during the manufacturing process or due to mishandling during transportation or storage. 2. Edge defects: These can include burrs or uneven edges on the coil. They can be caused by improper slitting or cutting processes. 3. Coating defects: If the aluminum coil is coated with a protective or decorative coating, defects such as peeling, cracking, or uneven coating thickness can occur. This can be caused by improper application or curing of the coating. 4. Corrosion: Aluminum is generally known for its corrosion resistance, but it can still be prone to corrosion in certain environments. Corrosion can manifest as pitting, staining, or white powdery deposits on the surface of the coil. 5. Alloy defects: In some cases, the aluminum alloy used in the coil can have defects such as inclusions, impurities, or improper alloy composition. These defects can affect the mechanical properties and overall performance of the coil. 6. Coil shape defects: Aluminum coils should have a uniform and consistent shape, but defects such as coil set (where the coil retains a curvature after unwinding) or camber (where the coil has a slight curvature across its width) can occur. These defects can be caused by improper tension or cooling during the manufacturing process. 7. Weld defects: If the aluminum coil is made by welding together multiple sheets or strips of aluminum, defects in the welds can occur. These can include incomplete welds, cracks, or porosity. These defects can weaken the coil and affect its structural integrity.

Send your message to us

6063 Aluminum Coil Manufacture Five Bar Pattern 5052 4mm Aluminum Checkered Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords