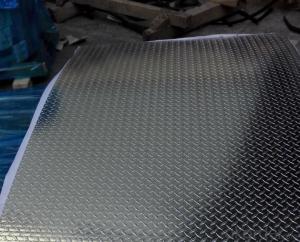

Custom Aluminum Sheets - Embossed Aluminium Plate/Sheet Alloy 5083 H12

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Embossed Aluminium Plate/Sheet Alloy 5083 H12

Description

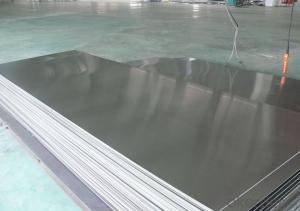

Aluminium sheet | |||||

Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

A1050,A1060, A1070, A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

3A21, A3003, A3105, A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

A5052, A5005, A5083, A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

A6061, A6082, A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

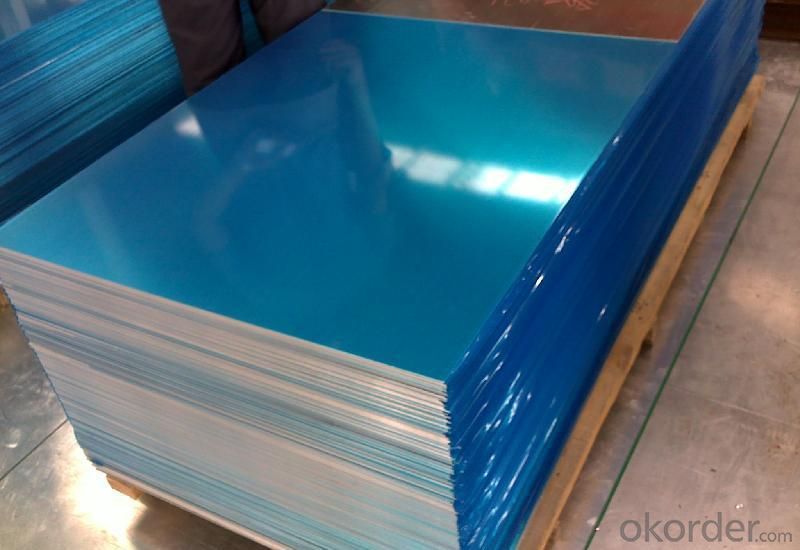

Packing: Export wooden pallets. The bundle weight not exceed 2MT. Loading: by 1x20GP, 1X20GP can load about 18MT | |||||

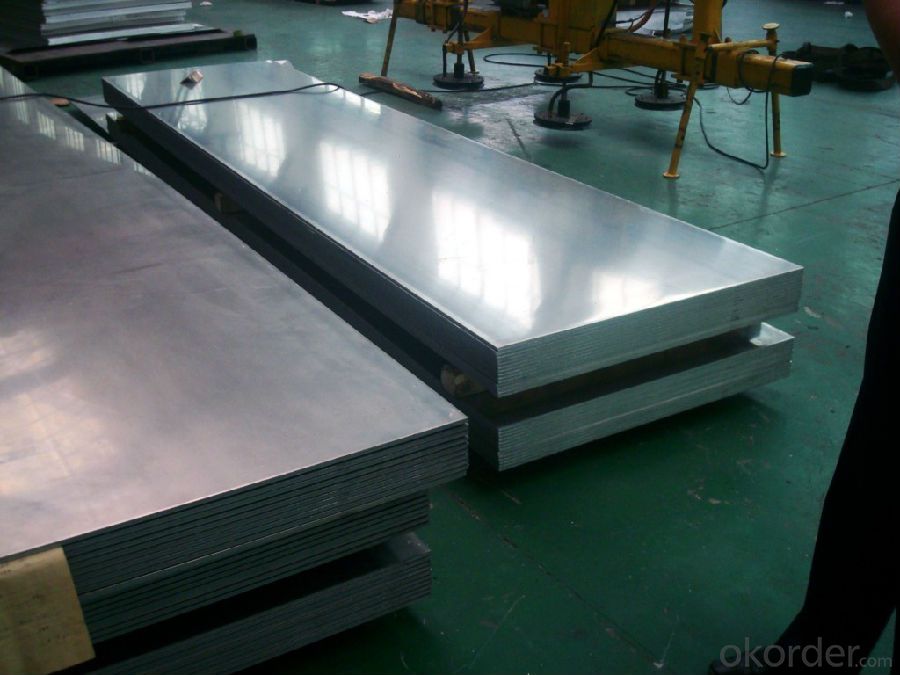

Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

MOQ | 5 tons | ||||

Payment term | T/T,L/C | ||||

Delivery Time | 15-30 days after 30% T/T payment or receiving L/C copy | ||||

Kind attention: Specifications can be customized as the customer’s requirements. | |||||

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: can the oxide film on the surface of aluminum sheet prevent the erosion of acid liquid? Why?

- yes, acid can react with aluminum oxide , generating salt and water, but its anti-corrosion will be stronger if oxide film on the surface is enough dense.

- Q: Is it possible to use aluminum sheets as a material for interior walls?

- <p>Yes, aluminum sheets can be used for interior walls. They are known for their durability, resistance to corrosion, and ease of maintenance. Aluminum sheets can also be painted or finished in various ways to match different interior design styles. They are lightweight, which makes them easy to install, and they provide good thermal insulation. However, it's important to consider the acoustic properties and the need for proper insulation to prevent condensation, especially in colder climates.</p>

- Q: How could two pieces of aluminium flakes be welded together?

- You can use argon arc welding, connect the positive pole with alternating current,aluminum wire as the welding wire.

- Q: Is it possible to use aluminum sheets as a material for interior wall decoration?

- <p>Yes, aluminum sheets can be used for interior wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications. Aluminum sheets are also easy to install and maintain, and they can be painted or finished in various ways to match different design styles. However, it's important to ensure proper installation and adherence to local building codes and regulations.</p>

- Q: This question asks for the method to determine the quantity of aluminum sheet required for a specific project.

- <p>To calculate the amount of aluminum sheet needed for a project, first determine the dimensions of the area to be covered. Measure the length and width to find the total area in square units. If the project involves complex shapes, break it down into simpler shapes like rectangles and circles, and calculate the area for each. Multiply the total area by the thickness of the aluminum sheet required. Finally, consider any additional material for overlaps or wastage, typically around 5-10%. The total volume calculated will give you the amount of aluminum sheet needed for the project.</p>

- Q: How to clean the aluminium oxide on the surface of aluminum? What kind of materials should we use to clean the thin aluminum sheet, and what's the concentration?

- You can sprinkle the mix of Alkaline water,vinegar,washing powder and liquid detergent on the surface. And after a period of time, rub it with soft silk, after it being dry,sprinkle again and rub until it's clean.

- Q: What are the different cutting tools used for aluminum sheets?

- There are several cutting tools that can be used for aluminum sheets. 1. Circular Saw: A circular saw with a carbide-tipped blade can be used to cut aluminum sheets. It is important to use a blade with fine teeth to ensure a clean and smooth cut. 2. Jigsaw: A jigsaw equipped with a metal-cutting blade can also be used to cut aluminum sheets. This tool allows for more intricate cuts and curves. 3. Bandsaw: A bandsaw with a fine-toothed blade is another option for cutting aluminum sheets. It provides a straight and precise cut, making it ideal for larger or thicker sheets. 4. Shears: Electric or manual shears can be used to cut aluminum sheets. They are particularly useful for straight cuts and can achieve a clean finish. 5. Plasma Cutter: A plasma cutter can be used for cutting aluminum sheets, especially for thicker materials. It uses high-temperature plasma to melt through the metal, resulting in a precise and efficient cut. 6. Laser Cutter: Laser cutting machines are commonly used for cutting aluminum sheets. They produce a high-powered laser beam that melts and vaporizes the material, allowing for precise and intricate cuts. It is important to wear appropriate safety gear, such as gloves and goggles, when using any of these cutting tools. Additionally, choosing the right tool depends on the thickness of the aluminum sheet and the desired cut. It is recommended to consult a professional or refer to the manufacturer's guidelines for the specific tool being used.

- Q: What is the usage of aluminum sulfate for every ton of paper produce for kraft paper and news print

- Aluminium sulphate was the most extensively used chemical raw material in the papermaking industry. Its primary use was in the rosin sizing of paper where the rosin soap was reacted with aluminium sulphate to impart hydrophobis characteristics to the paper. The alum had a side benefit in fixing all types of anionic substances into the paper web. All types of paper, even those that were not sized, such as newsprint,were made using alum. This resulted in the paper being made under acidic conditions. The technology has changed markedly over the last 10 to 20 years with synthetic sizing agents being developed which do not require reaction with alum. In my country there is not 1kg of fine writing and printing paper made with rosin/ alum sizing, and no alum is used at all. Various synthetic highly charged cationic resins have been developed, such as polyacrylamide resins, polyethyleneimine resins, etc, whic are used as fixing and retention agents, so that alum has been virtually eliminated. To sum up the importance of aluminium sulphate as a papermaking chemical is now very limited.

- Q: Can aluminum sheets be used for heat exchanger fins?

- Yes, aluminum sheets can be used for heat exchanger fins. Aluminum is a commonly used material for heat exchanger fins due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion.

- Q: Can the aluminum sheets be used for manufacturing aircraft parts?

- Yes, aluminum sheets can be used for manufacturing aircraft parts. Aluminum is a lightweight and durable material that is commonly used in the aerospace industry. It possesses excellent strength-to-weight ratio, corrosion resistance, and good formability, making it suitable for various aircraft applications. Aluminum sheets can be easily fabricated into complex shapes and are used to manufacture components such as wings, fuselages, panels, and structural supports in aircraft. Additionally, aluminum's high conductivity allows for efficient heat dissipation in critical areas of the aircraft. Overall, aluminum sheets are a preferred choice for manufacturing aircraft parts due to their favorable properties and reliability in the aerospace industry.

Send your message to us

Custom Aluminum Sheets - Embossed Aluminium Plate/Sheet Alloy 5083 H12

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords