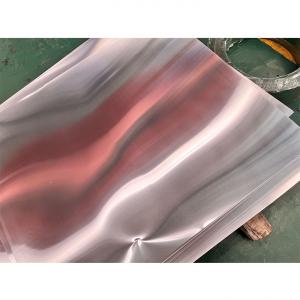

1 Thick Aluminum Plate

1 Thick Aluminum Plate Related Searches

1 Inch Thick Aluminum Plate 1 2 Thick Aluminum Plate Aluminum Plate 1 Inch Thick 1 4 Thick Aluminum Plate 1 Inch Aluminum Plate 1 Aluminum Plate 1 8 Thick Aluminum Plate 1 4 Inch Thick Aluminum Plate Aluminum Plate 1 2 Inch Thick 1 8 Inch Thick Aluminum Plate Aluminum Plate 1 8 Thick 1 2 Aluminum Plate 2 Thick Aluminum Plate 1/8 Inch Thick Aluminum Plate 1/8 Thick Aluminum Plate 1/4 Inch Thick Aluminum Plate 1 4 Aluminum Plate Aluminum Plate 1/4 Thick 1/2 Inch Thick Aluminum Plate Aluminum Plate 1/4 Inch Thick 1 2 Inch Aluminum Plate 1/4 Thick Aluminum Plate Thick Aluminum Plate Aluminum Plate 1/2 Inch Thick Aluminum Plate 1/2 Thick 1/2 Thick Aluminum Plate 2 Inch Thick Aluminum Plate Aluminum Plate 1/8 Thick 3 4 Thick Aluminum Plate 1 4 Inch Aluminum Plate1 Thick Aluminum Plate Supplier & Manufacturer from China

1 Thick Aluminum Plate is a type of metal product that is widely used in various industries due to its durability and strength. It is made from high-quality aluminum, which ensures its resistance to corrosion and its ability to withstand high temperatures. This product is known for its excellent performance in different environments, making it a popular choice for a range of applications.The 1 Thick Aluminum Plate finds its use in numerous scenarios, such as construction, automotive, aerospace, and manufacturing industries. It is utilized in the production of various components, including structural parts, machine parts, and decorative elements. Its versatility allows it to be easily cut, shaped, and welded, making it a go-to material for many engineering and design projects. The 1 Thick Aluminum Plate's lightweight nature also contributes to its popularity, as it reduces the overall weight of structures and components without compromising on strength.

Okorder.com is a reputable wholesale supplier of the 1 Thick Aluminum Plate, offering a vast inventory to cater to the needs of various industries. As a leading online platform, Okorder.com ensures that customers have access to a wide range of products, including the 1 Thick Aluminum Plate, at competitive prices. With a commitment to quality and customer satisfaction, Okorder.com is the go-to destination for businesses looking to source high-quality aluminum plates for their projects.

Hot Products