Superplastic Aluminum Sheets 1xxx Hot Rolled

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets 1xxx Hot Rolled Description

Aluminum Sheets 1xxx Hot Rolled is cut from aluminum coils 1xxx. The aluminum content of Aluminum Sheets 1xxx Hot Rolled is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets 1xxx Hot Rolled is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets 1xxx Hot Rolled

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

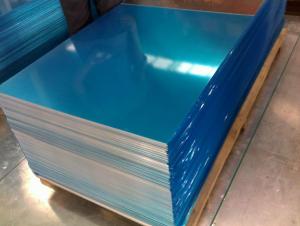

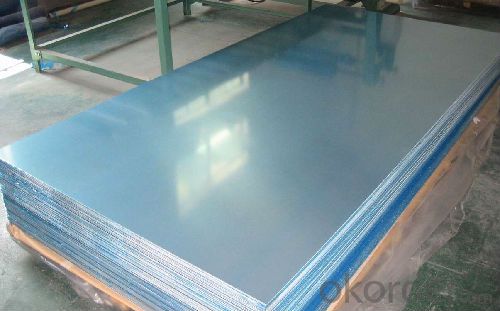

3.Aluminum Sheets 1xxx Hot Rolled Images

4.Aluminum Sheets 1xxx Hot Rolled Specification

| Alloy | AA1xxx (AA1050,AA1060,AA1070,AA1100 etc. |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thickness | 0.2mm-100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ ofAluminum Sheets 1xxx Hot Rolled

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets 1xxx Hot Rolled products.

B.When will you deliver the products?

The Aluminum Sheets 1xxx Hot Rolled will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What can I do to remove the paint from the painted aluminum sheet?

- Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a durable and corrosion-resistant material that can withstand various weather conditions, making it ideal for outdoor applications.

- Q: What specific considerations or precautions need to be taken into account when working with thin aluminum sheets?

- <p>When working with thin aluminum sheets, it's important to handle them carefully to prevent denting or bending. Use gloves to avoid oils and moisture from hands that can cause corrosion. Ensure proper ventilation when cutting or shaping to avoid inhaling aluminum dust. Use sharp tools to minimize the risk of tearing or marring the surface. Also, consider the specific alloy's properties, as different aluminum alloys have varying strengths and malleabilities. Always follow safety guidelines and use appropriate protective equipment.</p>

- Q: What are the different methods of forming aluminum sheet?

- There are several methods of forming aluminum sheet, each with its own advantages and limitations. 1) Rolling: This is the most common method used to manufacture aluminum sheet. It involves passing aluminum ingots through a series of rolling mills that gradually reduce the thickness of the metal until the desired sheet thickness is achieved. Rolling is highly versatile and can produce sheets with precise thicknesses and a wide range of sizes. 2) Extrusion: In this method, a heated aluminum billet is forced through a die to produce a continuous sheet. Extrusion is commonly used to produce sheets with complex cross-sectional shapes and consistent thickness. It is particularly suitable for producing aluminum sheets with a consistent pattern or texture. 3) Casting: Casting involves pouring molten aluminum into a mold and allowing it to solidify. This method is often used to produce large aluminum sheets with irregular shapes or intricate designs. However, the thickness of cast aluminum sheets may not be as consistent as those produced by rolling or extrusion. 4) Stretch forming: In stretch forming, a sheet of aluminum is clamped around its edges and stretched over a die to achieve the desired shape. This method is commonly used to produce curved or contoured aluminum sheets, such as those used in automotive or aerospace applications. 5) Spinning: Spinning is a process where a rotating disk or mandrel is pressed against a sheet of aluminum to shape it into a desired form. This method is commonly used to produce cylindrical or conical aluminum sheets, such as those used in lighting fixtures or cookware. 6) Deep drawing: Deep drawing involves placing a flat sheet of aluminum into a die and using a punch to force the metal into the desired shape. This method is commonly used to produce aluminum sheets with deep, cup-like shapes, such as those used in beverage cans or automotive parts. Overall, the choice of method for forming aluminum sheet depends on the desired shape, thickness, and complexity of the final product, as well as the production volume and cost considerations.

- Q: What are the standards and certifications available for aluminum sheets?

- Aluminum sheets can be evaluated for quality and compliance with industry requirements through various standards and certifications. Some well-known ones include: 1. ASTM International Standards: Developed by the American Society for Testing and Materials (ASTM), these standards focus on aspects like chemical composition, mechanical properties, and dimensional tolerances. They promote consistent quality across different aluminum sheet products. 2. ISO 9001: This globally recognized certification establishes guidelines for quality management systems. Aluminum sheet manufacturers with ISO 9001 certification demonstrate their commitment to meeting customer requirements, continuous improvement, and strict quality control processes. 3. ASME Standards: The American Society of Mechanical Engineers (ASME) has specific standards for aluminum sheet materials used in pressure vessels, piping, and other applications. These standards ensure the safety and reliability of aluminum sheets in critical applications. 4. MIL-Specifications: The United States Department of Defense (DoD) has developed military specifications (MIL-Specs) for materials, including aluminum sheets. These specifications define the requirements for military-grade aluminum sheets, ensuring their suitability for defense applications. 5. EN Standards: The European Committee for Standardization (CEN) has established a series of European Norm (EN) standards for aluminum and aluminum alloys. These standards cover chemical composition, mechanical properties, and surface finishes, ensuring compatibility and consistency in the European market. 6. RoHS Compliance: Compliance with the Restriction of Hazardous Substances (RoHS) is crucial for aluminum sheets used in electrical and electronic equipment. This certification guarantees that the aluminum sheets are free from hazardous substances, ensuring environmental safety. Manufacturers and suppliers of aluminum sheets must adhere to these standards and certifications to ensure their products are of the highest quality, safety, and suitability for specific applications.

- Q: The user is asking if aluminum sheets can be used as a substitute for metal siding in construction.

- <p>Yes, aluminum sheets can be used to replace metal siding. They are lightweight, durable, and resistant to corrosion, making them a popular choice for siding. Aluminum sheets can be painted or finished to match various architectural styles and are low maintenance. However, it's important to ensure that the aluminum sheets are of the appropriate gauge and quality for the application, and that they are installed correctly to ensure longevity and performance.</p>

- Q: How does 1200X1200X15 6061 aluminum, CNC processing, the plane degree can reach the number of my clients to 0.2, but I used to use the MS 1000X1500X70 to the material processing, the flatness is only 1, please experienced friend to help, thank you

- Buy aluminum plate before processing, we must plastic, rolling. Processing should leave margin, release the stress, no precision requirements of the hole to do first, after the two plastic. In the semi gold processing, plastic grinding before finishing. We do that every big 700*700*12, and do the flatness down 0.03-005.

- Q: What paint is better to paint on the brushed aluminum sheet? Simple process and good adhesion!

- Car paint is better, you can go to the auto paint repair department to buy a little, but pay attention to two points: 1., the oil on the aluminum alloy solvent cleaning. 2. can not spray thick, otherwise it will rise.

- Q: Can the aluminum sheets be used for manufacturing food storage containers?

- Yes, aluminum sheets can be used for manufacturing food storage containers. Aluminum is a highly suitable material for food storage due to its non-toxic properties, excellent heat conductivity, and resistance to corrosion.

- Q: Are 101 aluminum sheets suitable for solar panel frames?

- Indeed, solar panel frames can be made using 101 aluminum sheets, which are highly suitable for this purpose. The grade 101 aluminum is widely utilized and recognized for its outstanding strength and ability to resist corrosion. These characteristics render it an optimal material for constructing frames that can endure the elements and offer ample support for solar panels. Furthermore, 101 aluminum sheets are lightweight, facilitating the straightforward installation and transportation of solar panels. In summary, the strength, corrosion resistance, and lightweight properties of 101 aluminum sheets make them a fitting option for solar panel frames.

Send your message to us

Superplastic Aluminum Sheets 1xxx Hot Rolled

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords