1 Inch Thick Aluminum Sheets - Five Bar Treadplate Aluminium Panel AA1xxx for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

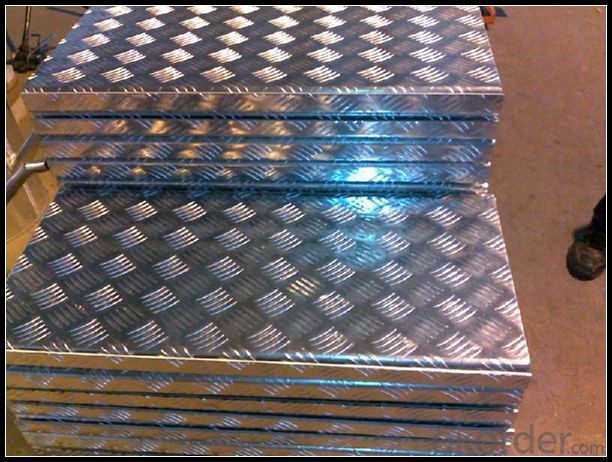

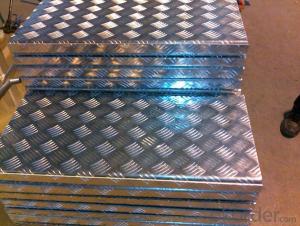

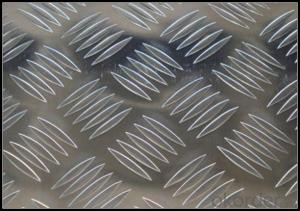

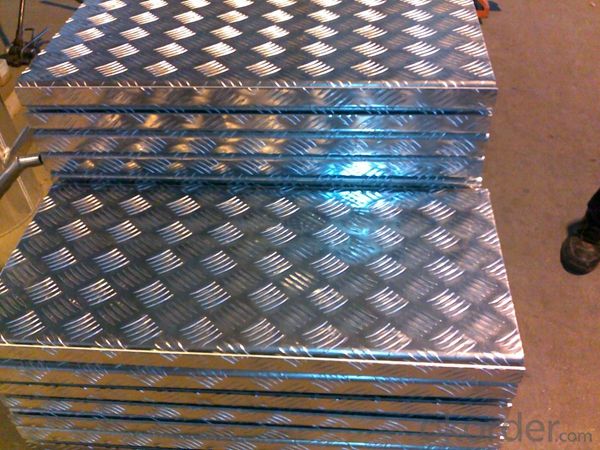

5. Image of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

6. Package and shipping of Five Bar Treadplate Aluminium Panel AA1XXX for Tool Box

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets prone to warping?

- Yes, aluminum sheets can be prone to warping under certain conditions. Aluminum is a relatively soft metal, meaning it is more susceptible to bending or distorting compared to other metals like steel. However, the extent to which aluminum sheets warp depends on various factors such as the thickness of the sheet, the specific alloy used, the temperature it is exposed to, and the level of stress applied to it. Thinner aluminum sheets are generally more prone to warping as they have less structural integrity. Thicker sheets, on the other hand, are more resistant to warping due to their increased rigidity. Additionally, the specific alloy composition of the aluminum sheet can influence its susceptibility to warping. Temperature fluctuations can also cause aluminum sheets to warp. When exposed to high temperatures, aluminum expands, and if not properly supported or restrained, it may bend or warp. Similarly, rapid cooling can cause contraction, resulting in warping. Lastly, the level of stress applied to aluminum sheets can contribute to warping. Excessive bending, pressure, or unevenly distributed loads can cause the sheet to deform. To minimize warping, it is important to handle aluminum sheets with care, support them adequately during temperature changes, and avoid applying excessive stress. Additionally, using thicker aluminum sheets or choosing certain alloys with higher tensile strength can help mitigate the risk of warping.

- Q: Are aluminum sheets fire-resistant?

- Aluminum sheets possess properties that enhance their fire resistance when compared to other materials, although they are not inherently fire-resistant. With a melting point of 1220°F (660°C), aluminum exhibits a resistance to ignition and burning in normal conditions. Moreover, when heated, aluminum does not emit flammable gases and has a low ignition temperature. When subjected to fire, aluminum sheets form a protective oxide layer that functions as a barrier, impeding further combustion and slowing the propagation of flames. This oxide layer also serves as insulation, safeguarding the aluminum from heat and diminishing the risk of structural failure. Nevertheless, it is crucial to acknowledge that despite aluminum sheets surpassing the fire resistance of materials like wood or plastic, intense heat can still cause damage or deformation. Consequently, it is imperative to consider alternative fire safety measures, including the utilization of fire-resistant coatings or the integration of fire suppression systems, to ensure optimal protection against fire hazards.

- Q: Can aluminum sheets be used for solar reflectors?

- Yes, aluminum sheets can be used for solar reflectors. Aluminum is highly reflective and has excellent heat resistance, making it an ideal material for solar reflectors. The reflective surface of aluminum sheets helps to redirect and concentrate sunlight onto solar panels or other solar devices, maximizing their energy efficiency. Additionally, aluminum is lightweight and durable, making it easy to handle and suitable for outdoor applications.

- Q: What's the maximum size of 3 mm thick aluminum sheet?

- See tolerance taggingIf there is no tolerance, see the accuracy level of the workpiece and check the tolerance listA 3-4 mm deviation is acceptable if the magnitude is not noted and is of no importanceThat is, the 3.5mm is OK, if the lower accuracy is generally 2.95

- Q: Are the aluminum sheets suitable for manufacturing kitchen utensils?

- Yes, aluminum sheets are highly suitable for manufacturing kitchen utensils. Aluminum is a lightweight and durable material that offers excellent heat distribution properties. It is corrosion-resistant, making it ideal for contact with food and liquids. Additionally, aluminum is non-reactive, which means it does not leach any harmful substances into the food being cooked or stored. It is also easy to clean and maintain, making it a popular choice for kitchen utensils. Overall, aluminum sheets are a reliable and efficient option for manufacturing a wide range of kitchen utensils.

- Q: How many atoms are in a 2.80 cm* 2.80cm*2.80cm cube of aluminum?

- 2.8cm * 2.8cm * 2.8cm= 21.95 cm^3 is volume of Aluminum present Density of Al = 2.7g/cm^3 Convert volume of aluminum into grams of Aluminum, make sure your units cancel 21.95 cm^3 * (2.7g/1 cm^3) = 59.26 g Al Next, find how many moles of Al you have. MW Al = 27g/mol 59.26/27 = 2.19 moles Al Use Avogadro's number to find number of atoms of Al - 2.19 moles Al * (6.022x10^23 atoms/1 mol Al) = 1.32x10^24 atoms Al

- Q: Are 101 aluminum sheets suitable for cryo-treating applications?

- No, 101 aluminum sheets are not suitable for cryo-treating applications.

- Q: I have a set of Chrome Aluminum rims, and two of them have scratches on them. So instead of buying new ones, is it possible to paint them. I was thinking black.

- Chrome rims and aluminum rims are not the same thing. There are chrome plated aluminum rims, but not many. Aluminum rims can be painted pretty easily as aluminum is pretty soft and you can sand it easily to paint it. If they are chrome plated it is harder to do because chrome plating is very hard, and doesn't sand easily, making it hard to get something to stick. Go to an auto paint store and tell them what you want to do. Use the best materials you can get, otherwise the paint will peel off and it will look worse than it does now.

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into diluted hydrochloric acid?

- Aluminum element is extremely activated and will react with oxygen, generating aluminum oxide, once being exposed in air, so there is a layer of aluminum oxide on the surface of daily aluminum products including aluminum sheet. When aluminum sheet is put into diluted hydrochloric acid, aluminum oxide on the surface will firstly react with hydrochloric acid, generating aluminium chloride and water, the process won’t generate bubble, but after finishing the reaction of aluminum oxide on the surface, when the exposed aluminum element reacts with hydrochloric acid, generating aluminium chloride and oxygen, the bubble appears.

- Q: Yesterday I picked up an 1988 performance bike. I bought it for the parts. It rode really good and now I'm deciding to keep it as is but I'm wondering if the bike is safe to ride. I've hear of aluminum horror stories and I'm assuming old aluminum isn't asnymore safe.Should I toss the frame and put the parts on a steel frame I have or ride it and not worry about it failing.

- I've ridden old Cannondales for years. I've never heard a horror story, if anything it is overengineered. With any frame, you need to see if there is any damage.

Send your message to us

1 Inch Thick Aluminum Sheets - Five Bar Treadplate Aluminium Panel AA1xxx for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords