1 Inch Wide Embossed Aluminum Strips with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

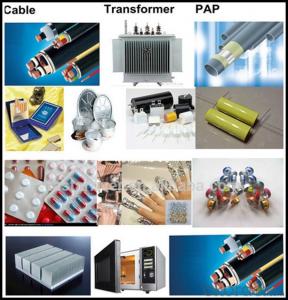

2. Application of Aluminum

(1).Exterior: shutters, sulfate doors...

(2).Interior: renovations find applications....

(3).Advertisement: fascia, shop fronts...

3. Feature of Aluminum

Several sulfates of aluminium find applications. Aluminium sulfate (Al2(SO4)3·(H2O)18) is produced on the annual scale of several billions of kilograms. About half of the production is consumed in water treatment. The next major application is in the manufacture of paper. It is also used as a mordant, in fire extinguishers, as a food additive (E number E173), in fireproofing, and in leather tanning. Aluminium ammonium sulfate, which is also called ammonium alum, (NH4)Al(SO4)2·12H2O, is used as a mordant and in leather tanning.[62] Aluminium potassium sulfate ([Al(K)](SO4)2)·(H2O)12 is used similarly. The consumption of both alums is declining.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

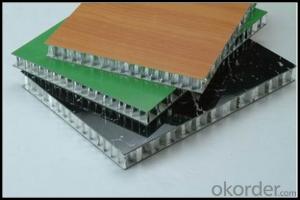

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Is it possible to utilize aluminum strips for creating signs or banners?

- <p>Yes, you can use aluminum strips to make signs or banners. Aluminum is lightweight, durable, and resistant to weather, making it a popular choice for outdoor signage. It can be cut, bent, and shaped easily to create various designs. Additionally, aluminum strips can be painted or printed on, allowing for customization with text and graphics. However, ensure that the aluminum is of the appropriate thickness and quality for your specific project to maintain its structural integrity and longevity.</p>

- Q: This question asks for a list of various types of aluminum components used in the automotive industry.

- <p>Aluminum is widely used in the automotive industry due to its lightweight and high strength. Different types of automotive aluminum parts include engine components such as cylinder heads and blocks, transmission housings, suspension parts like control arms and knuckles, wheels and rims, body panels, and doors. Other applications include heat exchangers, radiators, and various brackets and structural components. The use of aluminum can significantly reduce the weight of vehicles, improving fuel efficiency and performance.</p>

- Q: Is it possible to use aluminum strips in decorative applications?

- <p>Yes, aluminum strips can be used for decorative purposes. They are lightweight, durable, and available in various colors and finishes, making them suitable for a range of decorative applications. Aluminum strips are often used in interior design for trims, moldings, and accents, as well as in exterior applications such as facades and signage. Their resistance to corrosion and ease of maintenance also make them a practical choice for decorative elements in both residential and commercial settings.</p>

- Q: How to use batteries, magnets, cans of aluminum belt to make a rotating aluminum belt device, please explain

- On the left is an aluminum can top. It is on a vertical shaft and can rotate freely. On the right is a used water pen holder, the same on the vertical shaft, you can freely rotate.

- Q: This question asks about the various color options available for aluminum strips.

- <p>Aluminum strips are available in a variety of colors to suit different applications and aesthetic preferences. Common colors include silver, which is the natural color of aluminum, black, white, and clear anodized. Additionally, they can be coated or anodized in other colors such as gold, bronze, blue, red, and green. Custom colors are also possible with specialized coating or anodizing processes. The choice of color can depend on the specific use of the aluminum strip, such as for decorative purposes, architectural applications, or industrial uses where color coding is required.</p>

- Q: What are the various types of waterproofing materials that utilize aluminum strips in their composition?

- <p>Aluminum strips are used in several types of waterproofing materials due to their durability and resistance to corrosion. Some common types include: 1) Aluminum Foil Tapes: These are adhesive tapes with an aluminum foil backing, used for sealing joints and seams. 2) Aluminum Coated Fabrics: Fabrics coated with aluminum to provide a barrier against water and UV rays, often used in construction and roofing. 3) Aluminum Flashing: Sheets of aluminum used to cover joints and intersections in roofing and walls to prevent water infiltration. 4) Aluminum Waterproofing Membranes: These are flexible sheets that can be applied to surfaces to create a waterproof barrier. 5) Aluminum Coated Self-Adhesive Sheets: These are sheets with a self-adhesive backing and an aluminum coating, used for sealing and waterproofing applications. Each type serves specific waterproofing needs and is chosen based on the application and environmental conditions.</p>

- Q: What types of aluminum alloys are known for their higher resistance to corrosion compared to other aluminum types?

- <p>Yes, certain types of aluminum alloys exhibit greater resistance to corrosion. These include 3003, 5052, and 5083 aluminum alloys, which contain magnesium and manganese, enhancing their corrosion resistance. Additionally, 6061 aluminum, which contains magnesium and silicon, is known for its good resistance to atmospheric corrosion. These alloys are often used in marine environments and other corrosive conditions due to their superior corrosion resistance.</p>

- Q: What is the chemical composition represented by the formula for aluminum strips?

- <p>The chemical formula for aluminum strips is simply Al. Aluminum is a chemical element with the symbol Al and atomic number 13. It is a silvery-white, soft, nonmagnetic, and ductile metal in group 13 of the periodic table. Aluminum strips are made of this single element and do not contain any other elements or compounds.</p>

- Q: What types of metal sheets are better suited for specific applications and conditions?

- <p>Yes, different types of metal sheets are better suited for specific applications and conditions. For instance, stainless steel is excellent for food processing and marine environments due to its corrosion resistance. Aluminum is lightweight and conducts heat well, making it ideal for cookware and heat exchangers. Galvanized steel is used in construction for its rust protection. Copper is known for its high thermal and electrical conductivity, suitable for electrical wiring and plumbing. Each metal has unique properties that make it suitable for particular uses, and the choice depends on factors like strength, durability, weight, and cost.</p>

- Q: This question asks for methods to prevent rusting on aluminum strips during both installation and use.

- <p>To prevent rusting on aluminum strips, ensure that the aluminum is of high quality and free from impurities. Keep the strips clean and dry during installation and use. Avoid contact with corrosive substances. Apply a protective coating or sealant if necessary. Regularly inspect and clean the aluminum strips to remove any dirt or moisture that could lead to corrosion. In case of scratches or damage, promptly repair and seal the affected areas to prevent moisture penetration.</p>

Send your message to us

1 Inch Wide Embossed Aluminum Strips with Different Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords