1.0-6.0mm Thickness Aluminum Patio Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

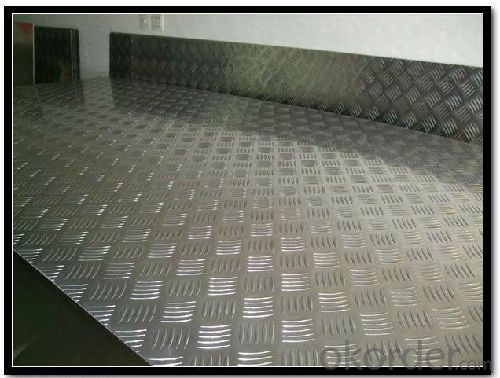

Aluminum tread sheet

1)Free sample available.

2)Manufacturer.

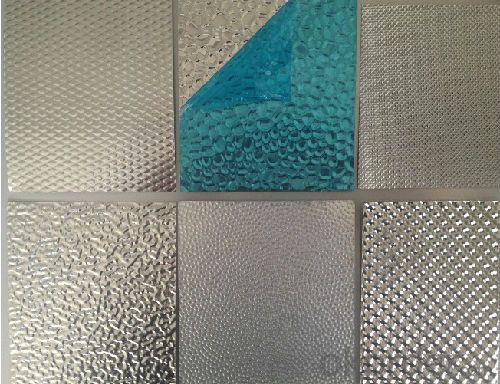

3)Different designs.

4)ISO 9001 and CE passed.

Specification

| Product | aluminum tread sheet |

| Alloy | 1050 1060 1100 3003 3004 5083 5754 |

| Temper | H12 H14 H16 H18 H22 H24 H26 H28 H112 |

| Thickness | 0.1-3.0 mm |

| Width | 8-2200 mm |

| Application | Regularly used in ships, vessels, vehicles, timber, automotive and aircraft panels welded, pressure should be strictly fireproof containers, refrigeration equipment, tower, drilling equipment, transportation equipment, missile components, armor, etc. |

| Certification | ISO 9001 and CE passed. |

| Welcome to visit our factory! | |

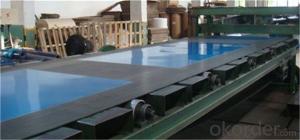

Packaging & Delivery

| Packaging Details: | aluminum tread sheet Standard seaworthy wooden case or pallet,and with pvc film inside |

| Delivery Detail: | 20 days upon receiving the deposit for embossed aluminum shee |

- Q: I'm 17 and it has been very hard finding a deodorant that makes me stop sweating. I told my dad I wanted to get Ban or Mitchum cause the percentage of Aluminum is very high. He said the Aluminum in deodorant has links to alzheimers, is that true? Also my sister said I could just scrub with soap morning and night, use regular deodorant without antipersperant and that would make me stop sweating too. But since i'm a teenager and my hormones are still weird would that be strong enough to stop sweat?

- aluminum oxide in antipersperant does lead to alzheimer's, yes. but antiperspirant is not deodorant, and deodorant does not contain aluminum. sweating is a natural bodily function. if you need to sweat, sweat. it's odor that should bother people.

- Q: What is the reflectivity of 101 aluminum sheets?

- The reflectivity of 101 aluminum sheets can vary depending on a few factors such as the surface finish, thickness, and any additional coatings or treatments applied to the sheets. Generally, aluminum has a high reflectivity, especially in the visible light spectrum. It can reflect around 80% to 90% of visible light, making it a popular material for reflective surfaces, mirrors, and various lighting applications. However, it is essential to note that the exact reflectivity of 101 aluminum sheets may differ based on specific manufacturing processes or variations in the material properties.

- Q: Can aluminum sheet be used for food packaging?

- Food packaging can utilize aluminum sheet, which is a popular choice due to its unique properties. This material is lightweight, flexible, and provides excellent protection against moisture, oxygen, and light. Consequently, it helps extend the shelf life of products and maintains their freshness. Aluminum sheet is commonly employed to package beverages, snacks, dairy products, and ready-to-eat meals. Furthermore, it is non-toxic and does not react with food, ensuring safety when in direct contact with consumables. Its versatility allows for easy customization to meet various packaging requirements. Overall, aluminum sheet is widely trusted and used for food packaging due to its durability, protective properties, and adherence to safety standards.

- Q: Aluminium magnesium alloy plate, 5052 aluminium plate, 5005 aluminium plate. 5252 aluminum plate performance and use

- Material details1 and 5052 aluminum magnesium alloy aluminum plate: 5052 aluminum plate belongs to the aluminum magnesium alloy aluminum plate, the use scope is widespread, especially in the construction industry cannot leave the alloy aluminum plate, also is the most promising aluminum alloy plate. The main alloy element of 5052 aluminum plate is magnesium, which has good corrosion resistance, good weldability, cold workability and medium strength.5052 aluminum plate is commonly used in the manufacture of aircraft and car fuel tanks, oil pipes, as well as traffic vehicles, ships sheet metal parts, instruments, street lamps, brackets and rivets, hardware, electrical appliances, such as shell.2 and 5005 aluminum magnesium alloy aluminum plate: 5005 aluminum plate, band strength and 3003, welding resistance, good processing, 5005 aluminum plate and 3003 alloy similar, with moderate strength and good corrosion resistance. The anodic oxide film is more bright than the oxide film on the 3003 alloy and is in harmony with the tone of the 6063 alloy.5005 aluminum plate is often used as conductor, cooker, instrument panel, shell and building decoration, building materials, internal and external materials, vehicle materials and so on.3 and 5754 aluminum magnesium alloy aluminum sheet: 5754 aluminum alloy has the characteristics of moderate strength, good corrosion resistance, weldability and easy processing and forming. It is a typical alloy in Al Mg alloy. In foreign countries, 5754 Aluminum Alloy plates of different heat treatment condition is the automobile manufacturing industry (car door, mould, seals), main materials used for canning industry.5754 aluminum is widely used in welding structure, storage tank, pressure vessel, ship structure and marine facilities, transport tanks as well as for the requirements of good processability, excellent corrosion resistance, high fatigue strength, high solderability and moderate intensity static situations.

- Q: Aluminum alloy cable tray is made of a series of aluminum sheets, a series of pure aluminum aluminum plate can do?

- 6 Department of the bar, pure aluminum is too soft, in fact, the price of 6 series with pure aluminum prices on the strength of almost guaranteed.

- Q: I have tried every possible method that I could find on the web for cleaning aluminum, tungsten, filler wire. Nothing has seemed to work. I've tried looking for leaks in the argon line. I'm getting decent welds but there is gunk in the welds for sure. I'm worried about overall strength of the welds. Does anybody out there know of a tried and true method for cleaning aluminum, tungsten, filler etc. that is sure to work? If I can follow that method and still have problems It could possibly be a problem with the machine. Any help would be much appreciated.

- Preweld cleaning requires two operations: oil/grease removal and oxide removal. As below, remove oils and greases first, then remove the oxide. Don’t reverse this order. Take the following steps before welding aluminum: 1. Remove oil, grease, and water vapor using an organic solvent such as acetone or a mild alkaline solution like a strong soap. You may also use citrus-based degreasers, but be sure to rinse and dry the part before welding. 2. Remove surface oxides with a stainless steel wire brush (used only for aluminum) or strong alkaline or acid. Many welding suppliers sell oxide-removal solutions in spray or squeeze bottles for local application. Exercise extreme care when handling these solutions, and again, rinse and dry the part before welding. 3. Assemble the joint. If it won't be welded immediately, cover the joint with brown Kraft paper to prevent dirt and grit in the air from getting into the joint. 4. Keep the aluminum dry and at room temperature. 5. Weld within a few days. Clean the joint again if it isn't welded within that time. Good luck!!!

- Q: Are aluminum sheets suitable for aviation applications?

- Yes, aluminum sheets are suitable for aviation applications. Aluminum is widely used in the aviation industry due to its lightweight, high strength-to-weight ratio, and corrosion resistance properties. It is used in the construction of aircrafts, including the fuselage, wings, and structural components. Aluminum sheets provide structural integrity, while also reducing the overall weight of the aircraft, which improves fuel efficiency and performance. Additionally, aluminum sheets can be easily formed and fabricated, making them versatile for various aviation applications.

- Q: This question asks for a list of various standard sizes of aluminum sheets that are commonly available in the market.

- <p>Aluminum sheet sizes can vary widely depending on the application and industry standards. Commonly available sizes include 1/8 inch, 1/4 inch, 3/8 inch, and 1/2 inch thicknesses, with widths ranging from 12 inches to 60 inches. Lengths can be from 4 feet to 20 feet or more. However, specific sizes can differ based on regional standards and manufacturers' offerings. It's also important to note that custom sizes can be ordered to meet specific project requirements. Always check with suppliers for the most current and detailed list of available sizes.</p>

- Q: What is the shear strength of 101 aluminum sheets?

- The shear strength of 101 aluminum sheets can vary depending on various factors such as the thickness of the sheet, the specific alloy composition of the aluminum, and the manufacturing process used. Generally, 101 aluminum sheets have a shear strength ranging from 20,000 to 30,000 pounds per square inch (psi). However, it is important to note that this is a general range and specific values may vary. To obtain the exact shear strength of 101 aluminum sheets, it is recommended to consult the material's technical data sheet or reach out to the manufacturer for more accurate information.

- Q: Are aluminum sheets suitable for chemical storage tanks?

- No, aluminum sheets are not suitable for chemical storage tanks as aluminum is highly reactive and can corrode when in contact with certain chemicals.

Send your message to us

1.0-6.0mm Thickness Aluminum Patio Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords