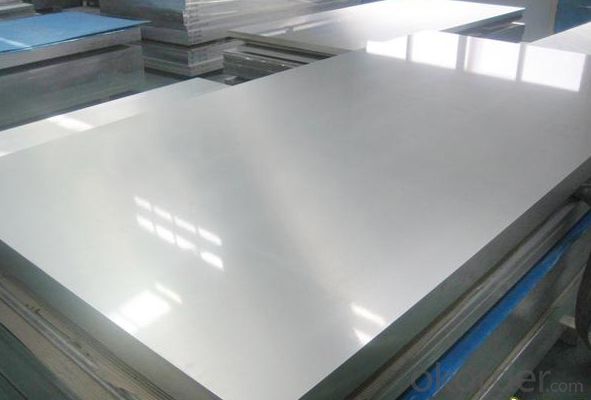

1/8 Inch Thick Mill Finish Aluminum Sheet 1100 with PVC Protection Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Discription:

Aluminum Sheets

Alloy No.: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3104, 3105, 5005, 5052, 5083, 5754, 8011, 8006, 8079, etc..

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm - 2100mm

1.Dark green surface, color changed into light green after exposure.Image checked easily.

2.Surface Quality :be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3.Faithful reproduction capacity, result at clear images.

4.Highly durable, long impression available.

5.Excellent sensitive character.

6.Resolution : 2%-98%

7.Material:1050/1060/1070/1100/2A16/2A06/2A12/2024/3003/3A21/4A01/5052/5005/5083/5A05/6061-T6/6063-T5/6082/7021/7075-T6/8011,etc

8.Certificate: ISO9001:2000, SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO)

9.Packing:First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation,wooden pallets

10.Application:Aircraft, automobile, train,Building wall, ceilings, roofing, furniture cabinet, lighting plate,etc

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Is it possible to use aluminum sheets as a material for exterior walls in regions with cold climates?

- <p>Yes, aluminum sheets can be used for exterior walls in cold climates. Aluminum is a durable and lightweight material with good thermal conductivity, which can be beneficial for heat transfer. However, it's crucial to use insulated aluminum panels or combine aluminum with insulation materials to prevent heat loss and maintain indoor comfort. Proper design and installation are essential to ensure the building envelope's thermal performance and structural integrity in cold weather conditions.</p>

- Q: Is aluminum a metal or a non-metal?

- Aluminum, a metal, holds the chemical element designation Al along with atomic number 13. Its categorization as a metal stems from its distinctive physical and chemical traits. The characteristics of aluminum include its display of a metallic luster, its ability to conduct heat and electricity, and its possession of considerable tensile strength. Moreover, aluminum is known for its malleability and ductility, enabling it to be effortlessly shaped into various forms. Furthermore, aluminum is typically observed in a solid state when subjected to room temperature, a trait commonly associated with metals. Consequently, aluminum is deemed a metal based on its properties and its placement within the periodic table.

- Q: So my new farrier comes out tomorrow and charges $20 more for aluminum shoes and I was wondering why that is? Is one better than the other? My horse is a TB hunter jumper. Tell me what you think :)

- Unless you have a specific reason for aluminum, the steel is better. It is more rigid, and supplies more support to the hoof wall. The aluminum bends if the horse steps on something, stressing the hoof wall. I used them for an OTTB who had weak, shelly hooves in front. He threw shoes like second graders throw spitballs... and when a steel shoe would come off, so would half his hoof wall. I switched to aluminum; the smaller nails stressed the hoof less, and the light weight put less stress on the nails. He still threw the shoes, but his hoof wall stayed intact - a great improvement. I evented and hunter paced this horse in these shoes. They wore pretty well, and I had them reset many times. I din't use the racing plates (even lighter and thinner), but got regular shoes made from aluminum. However, unless you have a similar hoof problem, I'd stick with steel. Edit: they're more expensive because aluminum costs more, and he can't buy them in bulk because fewer people use them. They're also harder to put on properly, because the aluminum nails bend really easily. They can be harder to shape, again because they bend easily and if you're used to bending steel, you have to develop the touch for it.

- Q: What are the different types of alloys used for painted aluminum sheets?

- There are several different types of alloys that are commonly used for painted aluminum sheets. One of the most popular alloys is 3003, which is known for its excellent corrosion resistance and high formability. This alloy is often used for applications where a smooth surface finish is desired, such as in the automotive industry. Another commonly used alloy is 5052, which offers a higher strength compared to 3003. This alloy is often used in marine and architectural applications due to its excellent corrosion resistance and ability to withstand harsh environments. It is also known for its good weldability and formability. Additionally, 6061 is a popular alloy choice for painted aluminum sheets. This alloy is known for its high strength and excellent machinability. It is often used in structural applications, such as in the manufacturing of aircraft parts and automotive components. Other alloys that are sometimes used for painted aluminum sheets include 2024, 5754, and 7075. These alloys offer specific properties that make them suitable for certain applications, such as high strength or improved corrosion resistance. Overall, the choice of alloy for painted aluminum sheets depends on the specific requirements of the application, such as the desired strength, corrosion resistance, and formability.

- Q: This question asks about the various types of aluminum sheets that are suitable for use in exterior applications, specifically those that can withstand outdoor conditions.

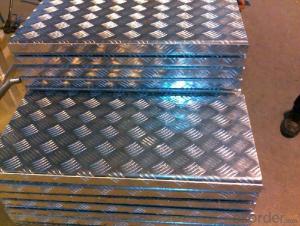

- <p>Aluminum sheets used for exterior applications come in various types, each with specific properties to withstand weather and environmental conditions. These include: 1. Mill Finish Aluminum Sheets: These have a natural aluminum finish and are used for applications requiring a raw, industrial look. 2. Anodized Aluminum Sheets: These are aluminum sheets that have been treated to increase their resistance to corrosion and wear. 3. Painted Aluminum Sheets: These are coated with a layer of paint for added protection and aesthetic appeal. 4. Embossed Aluminum Sheets: These have a textured surface and are used for decorative purposes or to provide a non-slip surface. 5. Perforated Aluminum Sheets: These are aluminum sheets with holes punched through them, used for ventilation or decorative purposes. Each type is chosen based on the specific requirements of the exterior application, such as durability, aesthetics, and environmental resistance.</p>

- Q: i know what aluminum is but oxide is not found on the periodic table, and the teacher also gave us a list of common oxidation numbers for polyatomic ions and it is not there also, can anyone help me?

- Mass Of Aluminum

- Q: Can aluminum sheets be used for pharmaceutical cleanrooms?

- Yes, aluminum sheets can be used for pharmaceutical cleanrooms. Aluminum is a commonly used material in cleanroom construction due to its excellent properties. It is lightweight, durable, and corrosion-resistant, making it suitable for maintaining a clean and sterile environment. Aluminum sheets can be utilized for wall panels, ceiling panels, and other surfaces within the cleanroom. These sheets can be easily cleaned and sanitized, ensuring that the pharmaceutical cleanroom remains free from contaminants. Additionally, aluminum is a non-porous material, which prevents the growth of bacteria and fungi. Therefore, aluminum sheets are a suitable choice for constructing pharmaceutical cleanrooms.

- Q: Is this aluminium plate ceiling dark keel or bright keel?

- I see you're a layman...... Where is the ceiling keel now?.... Now they are made of dark keel, so it's better to look at comfort, and we need to go through the lines and some pipes

- Q: Are aluminum sheets suitable for pharmaceutical applications?

- Yes, aluminum sheets are suitable for pharmaceutical applications. They are commonly used for packaging pharmaceutical products due to their excellent barrier properties, lightweight nature, and resistance to corrosion. Aluminum sheets help to protect the contents from moisture, oxygen, and light, ensuring the stability and effectiveness of pharmaceutical drugs. Additionally, aluminum sheets can be easily formed into different shapes, making them ideal for creating blister packs, caps, and closures for pharmaceutical packaging.

- Q: Can aluminum plate protect against radiation?

- Two. A brief introduction to radiation:Radiation refers to electromagnetic energy from the source part from the field source and transmitted, then return to the source, energy by electromagnetic waves or particles (such as the Alfa particle, beta particle) in the form of outward diffusion. All objects in nature, as long as the temperature is above zero degrees of absolute temperature, send the heat continuously in the form of electromagnetic waves and particles. This way of transmitting energy is called radiation. The radiation energy radiates straight from the source outward in all directions. The energy emitted by an object through radiation is called radiant energy. The radiation was calculated by roentgen / hour (R). One important feature of radiation is that it is "peer"". A body can radiate radiation to a second object, and at the same time a radiation to a target, regardless of the temperature of the object (gas). The term is commonly used in ionizing radiation. Radiation itself is a neutral term, but radiation from certain substances can be harmful.

Send your message to us

1/8 Inch Thick Mill Finish Aluminum Sheet 1100 with PVC Protection Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords