Aluminum 1in Thick Sheets AA5754 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets AA5754 Used for Construction Description

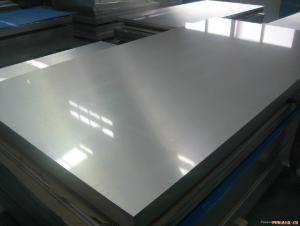

Aluminum Sheets AA5754 has great ductility, heat conductivity, anti-corrosion and moisture resistance properties which are very useful in the field of construction.

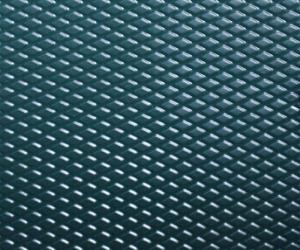

Aluminum Sheets AA5754is widely used for decorative purpose in construction, packing and appiance. It is also very commonly used for anti-slippery purpose in vehicles and public places.

2.Main Features of Aluminum Sheets AA5754 Used for Construction

• High weather resistance

• Anti scratch anticorrosion

• Subtle edges and elegant appearance

• High brightness and hardness.

3.Aluminum Sheets AA5754 Used for Construction Images

4.Aluminum Sheets AA5754 Used for Construction Specification

Alloy | AA5754 |

Temper | H14, H16, H24,H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA5754 Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA5754 Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA5754 Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

C/ What is the package?

Standard seaworthy export packing: wooden pallets with plastics protection

- Q: Can aluminum sheet withstand heavy loads?

- Indeed, the durability of aluminum sheet is such that it can endure substantial loads. Renowned for its exceptional strength-to-weight ratio, aluminum proves to be an exceptional selection for endeavors necessitating both resilience and load-bearing capacities. Notably prevalent in sectors like aerospace, automotive, construction, and marine, aluminum sheets are frequently employed in scenarios involving weighty burdens. Moreover, the innate corrosion resistance of aluminum further fortifies its capacity to bear heavy loads for extensive durations. Nevertheless, it is crucial to take into account the precise grade and thickness of the aluminum sheet, as diverse alloys and thicknesses yield differing load capacities.

- Q: Can 101 aluminum sheets be used in HVAC systems?

- Certainly, HVAC systems can utilize 101 aluminum sheets. Due to its exceptional thermal conductivity, resistance to corrosion, and lightweight attributes, aluminum is frequently employed in HVAC systems. The 101 aluminum alloy, a widely utilized grade, offers commendable strength and ductility, rendering it suitable for HVAC applications. It is commonly employed in the manufacturing of ducts, air handlers, heat exchangers, and various other components within HVAC systems. Moreover, aluminum sheets are highly malleable, allowing them to be easily molded and shaped in accordance with the specific demands of the HVAC system.

- Q: Is it possible to use aluminum sheets as a material for interior walls?

- <p>Yes, aluminum sheets can be used for interior walls. They are known for their durability, resistance to corrosion, and ease of maintenance. Aluminum sheets can also be painted or finished in various ways to match different interior design styles. They are lightweight, which makes them easy to install, and they provide good thermal insulation. However, it's important to consider the acoustic properties and the need for proper insulation to prevent condensation, especially in colder climates.</p>

- Q: Are the aluminum sheets suitable for manufacturing kitchen utensils?

- Yes, aluminum sheets are highly suitable for manufacturing kitchen utensils. Aluminum is a lightweight and durable material that offers excellent heat distribution properties. It is corrosion-resistant, making it ideal for contact with food and liquids. Additionally, aluminum is non-reactive, which means it does not leach any harmful substances into the food being cooked or stored. It is also easy to clean and maintain, making it a popular choice for kitchen utensils. Overall, aluminum sheets are a reliable and efficient option for manufacturing a wide range of kitchen utensils.

- Q: What are the different surface treatments for aluminum sheets to improve corrosion resistance?

- Some of the different surface treatments for aluminum sheets to improve corrosion resistance include anodizing, chromate conversion coating, powder coating, and painting.

- Q: Can 101 aluminum sheets be anodized?

- Yes, 101 aluminum sheets can be anodized.

- Q: Can aluminum sheets be used for food packaging?

- Yes, aluminum sheets can be used for food packaging. Aluminum is a safe and widely used material in the food industry due to its excellent barrier properties, resistance to moisture, and ability to maintain product freshness.

- Q: Can aluminum sheets be an alternative to glass in certain applications?

- Certain applications can consider aluminum sheets as an alternative to glass. Aluminum sheets provide various benefits over glass, making them suitable for specific scenarios. To begin with, aluminum sheets possess lightweight and durable characteristics, making them an excellent choice for industries like aerospace or automotive, where weight is a concern. Conversely, glass is relatively heavy and brittle, limiting its usage in certain environments. Moreover, aluminum sheets exhibit exceptional resistance to corrosion, making them a suitable option for marine or coastal applications, where glass may deteriorate over time due to exposure to saltwater. Aluminum sheets also possess a high strength-to-weight ratio, enabling greater design flexibility and structural integrity compared to glass. Furthermore, aluminum sheets offer superior thermal insulation properties in comparison to glass. They provide improved resistance to heat transfer, which is advantageous in applications where temperature control is crucial, like the construction industry. Additionally, aluminum sheets can be more cost-effective than glass in specific applications. The production and installation costs of aluminum sheets are often lower than glass, making them a more economical choice for large-scale projects. However, it is important to acknowledge that glass retains its own unique properties and advantages, such as transparency and optical clarity. Glass also has better resistance to scratches and chemical corrosion when compared to aluminum sheets. In conclusion, while aluminum sheets can serve as a viable alternative to glass in certain applications due to their lightweight, durability, corrosion resistance, thermal insulation properties, and cost-effectiveness, the final decision between the two materials depends on the specific requirements and limitations of the application at hand.

- Q: How do aluminum sheets handle extreme temperatures?

- The exceptional ability of aluminum sheets to handle extreme temperatures is widely recognized. This is primarily due to their high thermal conductivity, which enables them to effectively dissipate heat. As a result, they are suitable for applications involving high temperatures. Aluminum, with a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), can withstand a wide range of extreme temperatures without compromising its structural integrity. When exposed to intense heat, aluminum sheets do not easily deform or warp. Consequently, they are ideal for use in environments with high temperatures, such as industrial furnaces, automotive engines, and aerospace applications. Furthermore, aluminum has a low coefficient of thermal expansion, meaning it expands and contracts minimally when subjected to temperature variations. This significantly reduces the risk of cracking or structural damage. On the contrary, aluminum also performs exceptionally well in extremely cold temperatures. It remains durable and retains its strength even in freezing conditions. This makes aluminum sheets suitable for cryogenic applications, including the construction of liquid natural gas tanks or aerospace components that operate in low-temperature environments. In conclusion, aluminum sheets excel in handling extreme temperatures due to their high thermal conductivity, low coefficient of thermal expansion, and excellent structural integrity. Whether subjected to intense heat or extreme cold, aluminum sheets remain stable and reliable, making them the preferred choice in various industries.

- Q: Can aluminum sheet be used for automotive applications?

- Yes, aluminum sheet can be used for automotive applications. Aluminum is a lightweight and strong material that offers several advantages in the automotive industry. It is widely used in the production of car bodies, hoods, doors, and other structural components. Aluminum sheets are preferred for these applications because they provide excellent strength-to-weight ratio, corrosion resistance, and durability. Additionally, aluminum is easily formable, which allows for complex shapes and designs to be achieved. The use of aluminum in automotive applications also helps to improve fuel efficiency and reduce emissions due to its lighter weight. Overall, aluminum sheet is a suitable choice for automotive applications due to its numerous beneficial properties.

Send your message to us

Aluminum 1in Thick Sheets AA5754 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords