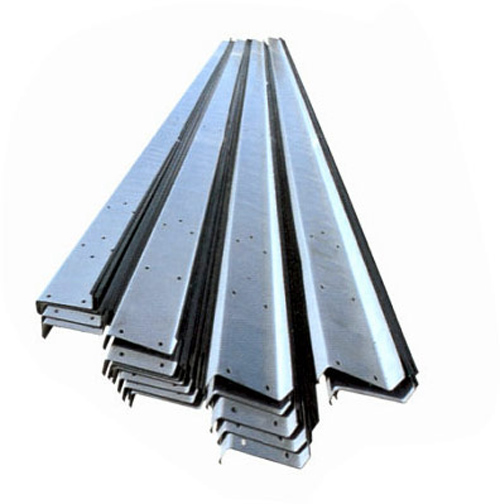

Z Channel Steel Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

In architecture, structural engineering or building, a purlin (or historically purline, purloyne, purling, perling) is any longitudinal, horizontal, structural member in a roof except a type of framing with what is called a crown plate. In traditional timber framing there are three basic types of purlin: purlin plate, principal purlin and common purlin.

Specifications:

1)Price:FOB $500-650

2)Material:Q195-Q420,Q195,Q215,Q235,Q345

3)Certification:ISO9001, SGS, BV

4)Payment term:TT,L/C

Advantages and features:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

- Q: How are steel structures used in industrial facilities?

- Industrial facilities rely heavily on the use of steel structures because of their robustness, longevity, and adaptability. These structures serve as a sturdy foundation for a wide range of applications, including factories, warehouses, power plants, refineries, and distribution centers. One primary application of steel structures in industrial facilities is the construction of the main building itself. By fabricating steel frames off-site and assembling them on-site, construction time and costs can be significantly reduced. These structures are capable of withstanding heavy loads, such as large machinery, equipment, and storage materials. The strength of steel also eliminates the need for internal support columns, allowing for spacious and flexible layout designs that maximize usable space. In addition to the main building structure, steel is also utilized for various secondary elements within industrial facilities. This includes platforms, mezzanines, catwalks, staircases, and handrails, which provide convenient access to different areas of the facility. Steel is the preferred material for these applications due to its ability to bear substantial loads and its resistance to corrosion and fire hazards. Moreover, steel structures can be easily modified or expanded to accommodate changes in production requirements or business growth. They can be adjusted to support additional equipment, mezzanines, or even entirely new sections, making them an economical choice for industrial facilities that need to adapt over time. Another advantage of steel structures in industrial facilities is their compliance with rigorous safety regulations. Steel is non-combustible, offering protection against fire hazards. It also possesses excellent seismic resistance, making it suitable for areas prone to earthquakes. Furthermore, steel structures can be designed to withstand extreme weather conditions, ensuring the safety of both personnel and assets within the facility. In conclusion, steel structures play a vital role in industrial facilities due to their strength, durability, versatility, and ability to meet safety regulations. They provide a solid foundation for the main building structure and are utilized for various secondary elements. Steel structures offer design flexibility and can be easily modified or expanded to accommodate evolving needs. Their resistance to corrosion, fire, and seismic events ensures the safety of personnel and assets within industrial facilities.

- Q: What are the design considerations for steel data centers?

- There are several important design considerations to keep in mind when designing steel data centers: 1. Structural Integrity: Steel is known for its strength and durability, making it an ideal material for data center construction. Designers must ensure that the steel framework is designed to withstand extreme weather conditions, seismic activity, and other potential hazards to maintain the structural integrity of the facility. 2. Thermal Management: Data centers generate a significant amount of heat due to the operation of servers and other equipment. Efficient thermal management is crucial to prevent overheating and ensure optimal performance. Steel data centers need to incorporate proper insulation, ventilation systems, and cooling mechanisms to maintain a stable and cool environment for the equipment. 3. Power Distribution: Data centers require a reliable and efficient power distribution system to ensure uninterrupted operation. Designers must consider the load capacity, redundancy, and backup power options, such as generators or uninterruptible power supply (UPS) systems. Steel data centers often require dedicated spaces for housing electrical equipment and cabling. 4. Scalability and Flexibility: Data centers need to be designed with scalability in mind to accommodate future growth and technological advancements. Steel structures allow for easy expansion and modifications, making it easier to accommodate additional equipment or reconfigure the layout as needed. 5. Security: Data centers store sensitive information and need to be highly secure. Design considerations include access control systems, surveillance cameras, fire suppression systems, and physical barriers to prevent unauthorized access and protect against potential threats. 6. Connectivity: Data centers rely on robust connectivity to ensure fast and reliable data transmission. Designers need to consider the routing and placement of network cables and fiber optic infrastructure to optimize connectivity within the facility. 7. Environmental Impact: Sustainable design practices should be considered when building steel data centers. Incorporating energy-efficient systems, green building materials, and renewable energy sources can help reduce the environmental impact and improve the facility's overall efficiency. 8. Maintenance and Accessibility: Designers must consider ease of maintenance and accessibility for equipment installation, repairs, and upgrades. Ample space, clear pathways, and proper cable management systems should be incorporated into the design to facilitate maintenance and ensure optimal performance. In summary, the design considerations for steel data centers revolve around structural integrity, thermal management, power distribution, scalability, security, connectivity, environmental impact, and accessibility. By addressing these considerations, designers can create high-performance and efficient data centers that meet the demands of modern technology.

- Q: How to calculate the purlin of steel structure.

- The general is not overlapped on type C purlin in terms of (can Z type), so the calculation length of single purlin is usually a span of 7.5 meters (the exact value may be deducted for each end of 10 mm).

- Q: What are the considerations for designing steel structures in areas with high wind loads?

- When designing steel structures in areas with high wind loads, there are several important considerations to take into account. 1. Wind Load Calculation: The first step is to accurately determine the wind loads that the structure will be subjected to. This requires careful assessment of local wind patterns, directionality, and intensity. Wind load calculations can be done using established codes and standards such as ASCE 7 or Eurocode. 2. Structural Stability: Steel structures must be designed to withstand the wind loads without experiencing excessive deflection or failure. The stability of the structure needs to be ensured by considering factors such as the shape and profile of the structure, bracing systems, and connections between structural members. 3. Material Selection: Choosing the appropriate grade of steel is crucial for withstanding high wind loads. High-strength steel with good ductility and toughness is often preferred as it provides better structural integrity and resistance against wind-induced forces. 4. Aerodynamic Design: The shape and profile of the structure should be optimized to minimize wind resistance and reduce the likelihood of vortex shedding, which can lead to dynamic instabilities. Aerodynamic features such as streamlined shapes or tapered sections can help to mitigate wind-induced vibrations. 5. Connection Design: The connections between structural members need to be carefully designed to ensure their integrity under high wind loads. Proper connection detailing, such as using high-strength bolts or welds, can enhance the overall strength and stability of the structure. 6. Foundation Design: The foundation system needs to be designed to transfer the wind loads from the structure into the ground. Adequate soil investigation and foundation design are critical to ensure that the foundation can resist the lateral forces generated by the wind. 7. Wind Breaks and Barriers: In some cases, additional wind breakers or barriers may be necessary to reduce the wind load on the structure. These can include features such as wind fences, wind screens, or adjacent buildings that can help redirect or dissipate the wind forces. 8. Maintenance and Inspection: Regular inspection and maintenance of the steel structure are essential to ensure its long-term performance in high wind load areas. This includes checking for corrosion, damage, or any signs of structural degradation that could compromise its integrity. By considering these factors, engineers can design steel structures that can safely withstand high wind loads, ensuring the safety and durability of the infrastructure in areas prone to strong winds.

- Q: How are steel structures used in the construction of residential complexes and apartments?

- Steel structures are commonly used in the construction of residential complexes and apartments due to their strength, durability, and versatility. They can support multiple floors, allowing for the creation of high-rise buildings. Steel beams and columns provide excellent load-bearing capacity, enabling the construction of large open spaces and flexible floor plans. Additionally, steel is resistant to fire, termites, and rot, making it a reliable choice for long-lasting structures. The use of steel also allows for faster construction times, reducing overall project costs.

- Q: How do steel structures accommodate different architectural styles?

- Steel structures can accommodate different architectural styles due to their versatility and flexibility. Steel can be molded and shaped into various forms, allowing architects to create intricate and unique designs. Additionally, steel can be easily combined with other materials such as glass and concrete, enabling the integration of different architectural styles. Steel's strength and durability also provide the necessary support for large spans and heights, enabling architects to explore bold and innovative designs that would be difficult to achieve with other materials. Overall, steel structures offer architects the freedom to explore and incorporate different architectural styles, making them a popular choice in modern construction.

- Q: What is the role of steel in architectural design?

- Steel plays a crucial role in architectural design as it offers strength, durability, and versatility. It allows for the creation of large, open spaces, thanks to its ability to span long distances without the need for excessive support columns. Steel's strength also enables architects to design tall buildings with minimal material usage, making it an efficient choice. Additionally, steel's flexibility allows for intricate and innovative designs, making it a popular material in modern architecture.

- Q: Which engineering structures are more economical and rational with steel structure?

- Heavy industrial buildings, large span structures, high-rise and super high-rise buildings, light steel roofs, mast structures.

- Q: How do steel structures contribute to the overall daylighting and views of a building?

- Steel structures can play a significant role in enhancing the overall daylighting and views of a building. One way steel structures contribute to daylighting is by allowing for larger windows and openings in the building envelope. Steel's high strength-to-weight ratio allows for the construction of thinner, more slender columns and beams, enabling architects to design structures with larger windows and fewer obstructions. This, in turn, allows more natural light to penetrate into the building, creating a brighter and more inviting interior space. Moreover, steel structures can facilitate the use of curtain walls, which are commonly made of glass or other transparent materials. These curtain walls provide expansive views of the surroundings, offering occupants a connection to the outside environment. Steel's strength and flexibility make it an ideal material for supporting the weight of curtain walls, allowing for greater flexibility in the design and placement of windows and glazed areas. In addition, steel structures can also incorporate techniques such as atriums or skylights, which further enhance daylighting and views. Atriums, often enclosed with glass, can act as lightwells, bringing natural light deep into the building's core. Similarly, skylights can introduce abundant daylight to areas that may otherwise be lacking in natural light. Steel's versatility and strength make it a reliable material for supporting these features, ensuring their stability and durability. Overall, steel structures provide the architectural and engineering flexibility necessary to maximize daylighting and views in a building. By allowing for larger windows, curtain walls, atriums, and skylights, steel structures contribute to a more naturally illuminated and visually appealing interior space, creating a pleasant and stimulating environment for occupants.

- Q: Can steel structures be designed to be sustainable?

- Certainly, sustainability can be achieved in the design of steel structures. Steel, known for its durability, recyclability, and energy efficiency, is an excellent choice for sustainable construction. To begin with, steel structures are renowned for their longevity and resilience. With its strength and ability to withstand harsh weather conditions, steel has a remarkably long lifespan. Consequently, steel structures necessitate less maintenance and replacement, resulting in reduced environmental impact. Moreover, steel ranks among the most recyclable materials worldwide. At the end of a structure's life cycle, steel components can be effortlessly dismantled and recycled. This not only decreases the demand for new steel production but also minimizes waste generation. Furthermore, advancements in steel fabrication and construction techniques have led to increased energy efficiency. Through the development of advanced technologies, energy consumption during steel manufacturing and construction has been significantly reduced. This progress contributes to the reduction of carbon footprint associated with steel structures. Additionally, steel structures can be designed to incorporate sustainable features such as energy-efficient insulation, solar panels, and rainwater harvesting systems. By integrating these features, energy consumption is further reduced, and the utilization of renewable energy sources is promoted, enhancing the overall sustainability of the structure. In conclusion, by considering the factors of durability, recyclability, energy efficiency, and the integration of sustainable features, steel structures can be effectively designed to be sustainable.

Send your message to us

Z Channel Steel Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches