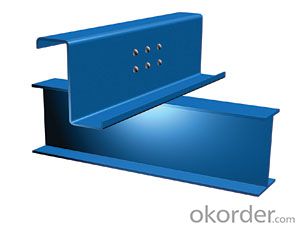

Prepainted Z Channel Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

1.Thickness:0.5mm to 4mm.

2.Grade:Q235,Q345.

3.Width:80mm to 300mm.

4.Material:Galvanized/prepaint

Specifications

1) Manufactured from high tensile galvanized steel

2) Despotic C&Z section steel, Z section steel is roll-formed from galvanized steel, specification to be complete

3) Make from quality raw material

4) Pre-punched holes based on detail design

5) Complete accessories package available

6) C purlin, Z purlin and H beam are widely used in factory buildings, large-span bridges, gymnasiums and portable houses

7) C purlin may be used in single spans and continuous spans in multi-bay buildings

8) We can make adjustment to meet your inquiries as we can do

Delivery and package

Delivery Time | 15-25 days after receipt of down payment |

Port | Xingang Port, Tianjin, China |

Packing: | 2ton/boundle with 5 steel strip.if you have any other requirement, it’s possible. The size of container: The inner size of container is below: 20 ft GP:5.8m(length)x 2.13m(width)x 2.18m(high) about 24-26 CBM 40 ft GP:11.8m(length)x 2.13m(width)x 2.72m(high)about 68 CBM |

- Q: How are steel structures designed to resist vibrations?

- Steel structures are designed to resist vibrations through various methods such as selecting appropriate structural members and connections, designing for dynamic loads, and incorporating damping devices. The selection of members with high stiffness and strength helps to minimize structural deformations and vibrations. Additionally, engineers consider the dynamic loads and design the structure to withstand these forces effectively. Damping devices, like tuned mass dampers or viscous dampers, can also be incorporated to absorb and dissipate vibrations, ensuring the structural integrity and stability of the steel structure.

- Q: How are steel structures used in cold storage warehouses and facilities?

- Steel structures are extensively used in cold storage warehouses and facilities due to their exceptional strength, durability, and flexibility. These structures provide numerous benefits in terms of construction, maintenance, and overall functionality. Firstly, steel structures offer excellent load-bearing capacity, allowing for the construction of large and spacious warehouses. The strength of steel enables these structures to support heavy loads of stored goods, including pallets, containers, and equipment. This ensures the safe storage of perishable items, such as food, pharmaceuticals, and chemicals, without the risk of structural failure. Secondly, steel structures are highly resistant to environmental factors, making them ideal for cold storage facilities. They can withstand extreme temperatures, including freezing conditions, without compromising their structural integrity. This is crucial for maintaining the required low temperatures inside the warehouse, keeping the stored products fresh and preventing spoilage. Moreover, steel structures are known for their durability and longevity. They are resistant to corrosion, rust, and deterioration, which is especially important in cold storage environments where moisture and condensation can be prevalent. Steel structures require minimal maintenance and have a longer lifespan compared to other building materials, ensuring the longevity and efficiency of the cold storage facility. In addition to their strength and durability, steel structures offer flexibility in design and construction. The versatility of steel allows for customized layouts and configurations to meet specific storage requirements. This includes the ability to add mezzanine levels, partition walls, and adjustable racking systems, maximizing the use of space and optimizing storage capacity. Furthermore, steel structures are quick and cost-effective to erect, reducing construction time and expenses. The prefabricated nature of steel components allows for off-site fabrication and on-site assembly, minimizing disruptions to the cold storage operations. Additionally, steel structures can be easily modified, expanded, or relocated if the storage needs change in the future. Overall, steel structures play a crucial role in cold storage warehouses and facilities by providing strength, durability, and flexibility. They ensure the safe storage of perishable goods, withstand harsh environmental conditions, require minimal maintenance, and offer customization options. With these advantages, steel structures are a preferred choice for cold storage applications, supporting the efficient and effective management of temperature-sensitive products.

- Q: What are the different types of steel stadiums?

- There are several different types of steel stadiums, including retractable roof stadiums, open-air stadiums, domed stadiums, and multi-purpose stadiums.

- Q: What is the process of erecting a steel structure?

- The process of erecting a steel structure typically involves several steps. First, the site is prepared, which includes clearing the land, leveling the ground, and ensuring proper drainage. Next, the foundation is constructed, which could be a concrete slab or footings, depending on the design. Once the foundation is ready, steel columns and beams are assembled and connected using welding or bolting techniques. After the framework is in place, secondary steel components such as braces, purlins, and girts are added to provide stability and support. Finally, the structure is enclosed with metal roof and wall panels, and finishing touches such as insulation, electrical and plumbing systems are installed. Throughout the process, safety measures and engineering standards are followed to ensure a sturdy and durable steel structure.

- Q: What are the different types of steel canopies and walkways used in buildings?

- In buildings, steel canopies and walkways of various types are commonly utilized for different purposes and designs. Here are some of the most prevalent kinds: 1. Cantilever Canopies: These canopies achieve an extended overhang without additional support by relying on a single column or beam. Often found at entrances or outdoor gathering areas, cantilever canopies provide shade and protection from the elements. 2. Truss Canopies: Constructed using interconnected beams, truss canopies create a robust and stable structure. They are commonly used in larger buildings or outdoor spaces where a wide span needs to be covered, such as parking areas or loading docks. 3. Glass Canopies: Designed to offer a transparent and aesthetically pleasing cover for entrances or walkways, glass canopies are often supported by steel frames or cables. This sleek and modern appearance provides protection from the weather. 4. Pedestrian Walkways: Also known as skybridges or footbridges, pedestrian walkways are elevated structures that connect different parts of a building or multiple buildings. These walkways, typically made of steel, offer a safe and convenient passage for people. 5. Covered Walkways: Used to shield pedestrians from rain, snow, or excessive sunlight while moving between different areas of a building or across a campus, covered walkways can have simple structures with a roof supported by steel columns or more intricate designs with walls and additional features. 6. Trellis Canopies: Often used in outdoor spaces like patios, courtyards, or gardens, trellis canopies consist of a lattice-like steel structure that provides partial shade and creates an appealing environment. 7. Tensile Canopies: Distinguished by their design, tensile canopies feature a fabric membrane stretched over a steel framework. This type of canopy offers a lightweight and flexible solution for covering large areas, such as stadiums or outdoor event spaces. When selecting the appropriate type of steel canopy or walkway, it is crucial to consider the specific needs and requirements of the building. Factors such as climate, purpose, design aesthetic, and budget will influence the selection process. Seeking advice from architects, engineers, and construction professionals can aid in determining the most suitable type for a building project.

- Q: What are the design considerations for steel military buildings?

- Some design considerations for steel military buildings include structural integrity, durability, security measures, adaptability, and functionality. The buildings need to be designed to withstand extreme weather conditions, potential attacks, and protect the personnel and equipment inside. They should also be adaptable to accommodate changing requirements and technologies. Additionally, the layout and features need to facilitate efficient operations and provide necessary amenities for the military personnel.

- Q: How are steel structures used in power plants?

- The strength, durability, and versatility of steel structures make them widely used in power plants. They have a crucial role in supporting heavy machinery, equipment, and infrastructure necessary for power generation. One primary application of steel structures in power plants is the construction of the main building or powerhouse. Steel frames create a robust skeleton that supports various components, including turbines, generators, boilers, and cooling systems. These structures can withstand the immense weight and vibrations produced by these machines, providing a safe and stable environment for their operation. Steel structures are also employed in the construction of storage facilities within power plants. These facilities store fuel, such as coal or natural gas, used for power generation. Steel tanks and silos are commonly used to store and safeguard these materials from the elements. The high strength and corrosion resistance of steel make it a suitable choice for these purposes. Additionally, steel structures are utilized for the construction of transmission towers and electrical substations within power plants. Transmission towers support high-voltage power lines, while substations house transformers and other electrical equipment. Steel's ability to bear heavy loads and withstand environmental factors, such as wind and seismic forces, make it an ideal material for these critical structures. Furthermore, steel structures serve auxiliary purposes in power plants. These include walkways, platforms, and staircases that provide safe access to different areas within the plant for maintenance and inspection activities. In conclusion, steel structures are indispensable in power plants as they provide the necessary strength and stability for heavy machinery, fuel storage, and electricity transmission and distribution. Their versatility makes them a popular choice for power plant construction worldwide.

- Q: How are steel structures used in the construction of retail centers and shopping complexes?

- Steel structures are commonly used in the construction of retail centers and shopping complexes due to their strength, versatility, and cost-effectiveness. Steel beams and columns provide the necessary support for large open spaces, allowing for flexible layouts and the incorporation of multiple levels. Additionally, steel's durability and resistance to fire and pests ensure the safety and longevity of these structures. Overall, steel structures offer efficient and practical solutions for creating modern, spacious, and visually appealing retail spaces.

- Q: How are steel structures designed for different transportation systems?

- Steel structures for different transportation systems are designed by considering factors such as the type of transportation, load requirements, safety regulations, and environmental conditions. The design process involves analyzing the anticipated loads, such as weight and impact forces, and selecting appropriate steel materials and components. Additionally, structural engineers use computer-aided design software and mathematical models to simulate and optimize the performance of these structures. The goal is to ensure that the steel structures are strong, durable, and capable of withstanding the specific demands of each transportation system.

- Q: How are steel structures designed for thermal comfort?

- Steel structures can be designed for thermal comfort through various strategies that aim to regulate the internal temperature and enhance occupants' comfort. One of the key considerations is insulation. By incorporating effective insulation materials in the walls, roofs, and floors of steel structures, heat transfer can be minimized, thereby reducing heat gain or loss from the external environment. This insulation helps maintain a stable internal temperature, reducing the need for excessive heating or cooling. Another aspect of thermal comfort design for steel structures is the integration of efficient HVAC (heating, ventilation, and air conditioning) systems. These systems can be designed to provide adequate heating or cooling based on the specific requirements of the building and its occupants. By ensuring proper airflow and temperature control, occupants can experience a comfortable indoor environment throughout the year. In addition to insulation and HVAC systems, other design considerations include the orientation and placement of windows and shading devices. By strategically locating windows to maximize natural light while minimizing direct sunlight exposure, passive solar heating can be utilized to provide additional warmth during colder months. Shading devices such as blinds or overhangs can also help reduce solar heat gain during warmer months, preventing overheating. Furthermore, the selection of appropriate building materials is crucial in steel structure design for thermal comfort. For instance, utilizing high-performance glazing with low solar heat gain coefficients can help reduce unwanted heat transfer. Additionally, incorporating thermal mass materials, such as concrete or stone, in the building envelope can help regulate temperature fluctuations by absorbing and releasing heat slowly. Lastly, the use of advanced technologies, such as smart controls and energy management systems, can optimize energy consumption and enhance thermal comfort. These systems can monitor and adjust temperature, humidity, and ventilation levels based on occupancy patterns and weather conditions, ensuring a comfortable and energy-efficient indoor environment. Overall, steel structures can be designed for thermal comfort by implementing insulation, efficient HVAC systems, strategic window placement, shading devices, appropriate building materials, and advanced technologies. By considering these factors, architects and engineers can create steel structures that promote a comfortable and sustainable living or working environment.

Send your message to us

Prepainted Z Channel Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords