Standard Size Steel Channel Bar, Metal Channel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Standard Size Steel Channel Bar, Metal Channel Bar

1.Our company enjoys high reputation on manufacturing and supplying U channel steel. Among those steel products, the U channel steel as per japanese, chinese and european can be regarded as our primary products.

Under those standard, the material grade includes: GB Q235B,GB Q345B/JIS G3192, SS400/EN 10025,S235JR and so on.

Here,the U channel steel as per japanese standard is posted just as reference.

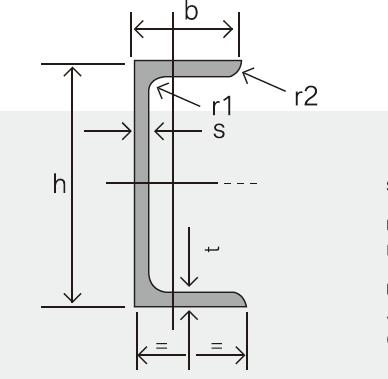

2. Dimension Figure:

Note:1.The height ranges from 50mm to 300mm

2.The breadth ranges from 25mm to 89mm

3.Theoretically speaking, the flange of U channel steel should bear stress, it’s to say that the U channel should be upright rather than lying under construction. Therefore, we strictly control the tolerance of the flange thickness.

3.The sections of U Channel Steel as per JIS Standard are shown in the below table:

JIS U CHANNEL | Standard h | Sectional b | Dimension s | t | Mass: Kg/m |

| (mm) | (mm) | (mm) | (mm) |

|

50x25 | 50 | 25 | 3.0 | 6.00 | 2.37 |

75X40 | 75 | 40 | 3.8 | 7.00 | 5.30 |

75X40 | 75 | 40 | 4.0 | 7.00 | 5.60 |

75X40 | 75 | 40 | 4.5 | 7.00 | 5.85 |

75X40 | 75 | 40 | 5.0 | 7.00 | 6.92 |

|

|

|

|

|

|

100X50 | 100 | 50 | 3.8 | 6.00 | 7.30 |

100X50 | 100 | 50 | 4.2 | 6.00 | 8.03 |

100X50 | 100 | 50 | 4.5 | 7.50 | 8.97 |

100X50 | 100 | 50 | 5.0 | 7.50 | 9.36 |

|

|

|

|

|

|

125X65 | 125 | 65 | 5.2 | 6.80 | 11.66 |

125X65 | 125 | 65 | 5.3 | 6.80 | 12.17 |

125X65 | 125 | 65 | 5.5 | 8.00 | 12.91 |

125X65 | 125 | 65 | 6.0 | 8.00 | 13.40 |

|

|

|

|

|

|

150x75 | 150 | 75 | 5.5 | 7.30 | 14.66 |

150x75 | 150 | 75 | 5.7 | 10.00 | 16.71 |

150x75 | 150 | 75 | 6.0 | 10.00 | 17.90 |

150x75 | 150 | 75 | 6.5 | 10.00 | 18.60 |

150x75 | 150 | 75 | 6.5 | 10.00 | 24.00 |

|

|

|

|

|

|

200X80 | 200 | 80 | 7.5 | 11.00 | 24.60 |

5.Mechanical Property of U Channel Steel as per JIS Standard:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS330 | ≧205 | ≧195 | ≧175 | ≧165 | 330-430 |

SS400 | ≧245 | ≧235 | ≧215 | ≧205 | 400-510 |

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

SS540 | ≧400 | ≧390 | - | - | ≧540 |

6. Chemical Composition of U Channel Steel as per JIS Standard:

Grade | Element(%) | |||

C | Mn | P | S | |

SS330 | -- | -- | ≦0.050 | ≦0.050 |

SS400 | ||||

SS490 | ||||

SS540 | ≦0.30 | ≦1.60 | ≦0.040 | ≦0.040 |

Note: we are also competent to supply structure steel u channel as per other sections, which depends on the customer's requirements for the quantity.

Applications of Standard Size Steel Channel Bar, Metal Channel Bar

U channel steel could be regarded as carbon steel or plain steel. Typically, it is stiff and strong. Carbon steels do rust easily, but they can be easily painted or primed. They are cheap so they are the normal choice for most fabrications. U channel steel is often used as supporting members, most commonly in the house raising industry to strengthen timber bears under houses. Transmission line towers.

And our products are widely used in Architectural Constructions,Telecom tower,Sub Station Structure,Microwave tower Factory and warehousing shed,Electrification projects, poles and earthing E.O.T. cranes,Material handling equipments,Ship building,Automobile

Package & Delivery of Standard Size Steel Channel Bar, Metal Channel Bar

The u channel steel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

And u channel steel could be loaded into 20ft or 40ft container, or by bulk cargo. If the weight of each bundle reaches less than 3.5 mt, the loading by break bulk cargo should be choosed. When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

In a word, we do try our best to satisfy all the customer's requirements.

Production Flow of Standard Size Steel Channel Bar, Metal Channel Bar

1.The steel billet shall be heated in the high temperature furnace.

2. The heated steel billet shall be rolled five to nine times with the aim of shaping the general figure of steel u channel.

3. The rolled steel u channel should be put onto the cooling bed to make the temperature low.

4. The steel u channel should be straighted on the straightener.

5. The straighted steel u channel will be cut into meters by saw, as per customer's requirements.

- Q: How do you calculate the maximum allowable stress for a steel angle?

- In order to determine the maximum allowable stress for a steel angle, one must take into account both the steel's material properties and the angle's specific geometry. To calculate this stress, follow these steps: 1. Find the yield strength (or tensile strength) of the steel angle, which can typically be found in engineering handbooks or material specification documents. The yield strength represents the maximum stress that the steel can endure without undergoing permanent deformation. 2. Decide on the desired safety factor for the application. The safety factor provides a margin of safety between the calculated maximum stress and the actual applied stress. The appropriate safety factor will vary depending on the specific application and industry standards, with common values ranging from 1.5 to 4. 3. Multiply the yield strength of the steel by the safety factor to calculate the maximum allowable stress for the steel angle. The formula is as follows: Maximum Allowable Stress = Yield Strength × Safety Factor For instance, if the yield strength of the steel angle is 300 MPa and the desired safety factor is 2, the maximum allowable stress would be: Maximum Allowable Stress = 300 MPa × 2 = 600 MPa It is crucial to use consistent units throughout the calculation, whether it is in megapascals (MPa), pounds per square inch (psi), or any other unit of stress. Please note that this calculation assumes the steel angle is subjected to a uniaxial stress state. If the angle is subjected to bending or torsional loads, additional calculations would be necessary to determine the maximum allowable stress based on the specific loading conditions and the angle's geometric properties.

- Q: How do steel angles perform in high-vibration environments?

- Steel angles perform well in high-vibration environments due to their inherent strength, stiffness, and durability. These structural components are specifically designed to resist bending and twisting forces, making them suitable for withstanding vibrations and maintaining structural integrity. Additionally, steel angles can be reinforced or dampened with additional materials to further enhance their performance in high-vibration environments.

- Q: Are there any industry standards or certifications for steel angles?

- Steel angles have industry standards and certifications. The main standard for steel angles is the ASTM standard, specifically the ASTM A36 specification. This specification outlines the necessary chemical composition, mechanical properties, and dimensional tolerances for structural steel angles. Aside from ASTM, other organizations like AISC and SJI also provide guidelines and standards for steel angles used in construction and structural engineering. These standards guarantee that steel angles meet specific requirements in terms of quality, strength, and performance. Moreover, certifications like ISO 9001:2015 and ISO 14001:2015 are widely recognized in the steel industry. These certifications indicate that a manufacturer has implemented a quality management system and complies with environmental management standards. Adhering to these industry standards and certifications is crucial for manufacturers, suppliers, and construction professionals. It ensures the dependability and safety of steel angles in various applications.

- Q: How do you calculate the axial load capacity of a steel angle?

- To calculate the axial load capacity of a steel angle, you need to consider several factors including the material properties of the angle, its dimensions, the type of loading, and the safety factor. First, you should determine the yield strength of the steel angle. This value represents the maximum stress the angle can withstand without permanent deformation. The yield strength can be obtained from the steel angle's specifications or by conducting material testing. Next, you need to measure the dimensions of the angle, including its length, thickness, and width. These values are crucial in determining the area of the cross-section of the angle. Once you have the yield strength and the cross-sectional area, you can calculate the axial load capacity using the formula: Axial load capacity = Yield strength × Cross-sectional area It is important to note that this formula assumes that the angle is subjected to direct axial loading. If the angle is subjected to combined loading or other complex loading conditions, additional calculations or structural analysis may be required. Moreover, it is customary to apply a safety factor to the calculated axial load capacity to account for uncertainties and ensure structural integrity. The safety factor is typically determined based on the specific application and industry standards. For example, a safety factor of 1.5 is commonly used in structural design. In summary, to calculate the axial load capacity of a steel angle, you need to know its yield strength, measure its dimensions, and apply the appropriate safety factor. This calculation provides an estimate of the maximum load the angle can bear without failure under axial loading conditions.

- Q: Can steel angles be used for stair treads?

- Yes, steel angles can be used for stair treads. Steel angles, also known as angle irons, are commonly used in construction and fabrication due to their strength and durability. When used as stair treads, steel angles provide a sturdy foundation for individuals to step on and walk up or down the stairs. The angled shape of the steel angles allows for better weight distribution and increased stability. Additionally, steel angles can be easily welded or bolted to the stair stringers or supports, making them a convenient and reliable choice for stair treads.

- Q: Can steel angles be used for support structures in sports facilities?

- Yes, steel angles can be used for support structures in sports facilities. Steel angles provide excellent strength and stability, making them suitable for supporting various components such as beams, trusses, and frames in sports facilities. They can effectively withstand heavy loads, ensuring the safety and durability of the structure. Additionally, steel angles are versatile and can be easily customized to meet specific design requirements, making them a reliable choice for support structures in sports facilities.

- Q: What is the typical length of a steel angle?

- The typical length of a steel angle can vary depending on the specific application or project requirements. However, standard lengths for steel angles often range from 10 to 20 feet.

- Q: What is angle iron?

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner.

- Q: Can steel angles be used as lintels or beams in construction?

- Steel angles can serve as lintels or beams in construction. These versatile structural elements lend support and strength to various kinds of structures. They are commonly utilized in construction projects due to their ability to bear heavy loads and resist bending or warping. When employed as lintels, steel angles are typically positioned horizontally above doors and windows to distribute the weight of the structure above and prevent sagging in the openings. As beams, steel angles can be employed to support floors, roofs, or other structural components. Their durability, versatility, and cost-effectiveness make them a popular choice compared to other materials. Nevertheless, it is crucial to seek advice from a structural engineer or construction professional to ensure that the specific steel angles being used are appropriate for the intended application and adhere to the necessary building codes and standards.

- Q: What are the different standards for steel angles?

- The different standards for steel angles include the American Society for Testing and Materials (ASTM) A36 standard, which is commonly used in the United States, and the European standard EN 10025, which is widely used in Europe. These standards outline the specific requirements for the chemical composition, mechanical properties, and dimensions of steel angles, ensuring consistency and quality in their production and use.

Send your message to us

Standard Size Steel Channel Bar, Metal Channel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords